Metal evaporation device applied to evaporation coatings

A metal evaporation and evaporation coating technology, which is applied in vacuum evaporation coating, metal material coating process, sputtering coating, etc., can solve the problems of reducing the service life of vacuum thermal evaporation coating device, no temperature monitoring, slow heating, etc. Achieve fast heating speed, reduce heat loss and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

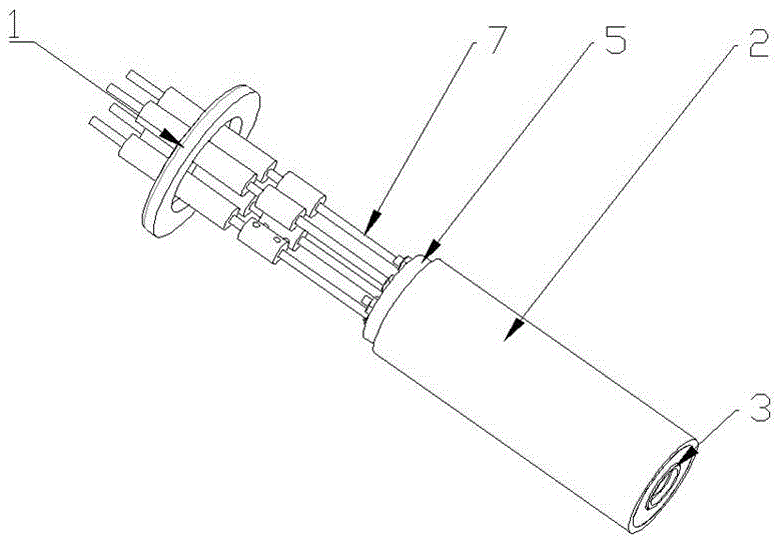

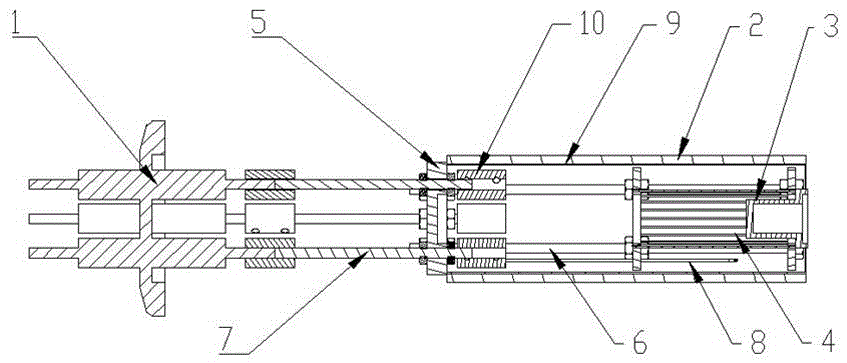

[0030] The invention provides a metal evaporation device applied to evaporation coating, which has the characteristics of low energy consumption. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

[0031] Such as figure 1 with figure 2 As shown, the metal evaporation device applied to evaporative coating includes a ceramic sealing electrode 1 and a metal evaporation body, wherein the metal evaporation body includes a ceramic tube 2, a crucible 3, a heating wire 4 and a main body support, and the main body support is composed of a plurality of supporting wire rods 6 respectively run through at least three pieces of alumina ceramic sheets 5, and the supporting wire rod 6 is relatively fixed with the alumina ceramic sheet 5 to form the main frame. Specifically, it consists of four supporting wire rods and three alumina ceramic sheets, and the supportin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com