Preparation method for high purity tantalum foil for organic light emitting diode (OLED)

A high-purity, tantalum foil technology, used in metal rolling and other directions, can solve the problems of low production efficiency, difficult processing, and unguaranteed product quality, and achieve the effect of low impurity content and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Aiming at the deficiencies of the prior art, the purpose of the present invention is to provide a high-purity tantalum foil for OLED with impurity content strictly in line with the standard, less structural defects, fine grain structure, high uniformity, and high isotropy of the internal mechanical properties of the plate material. Preparation.

[0039] The technical solution adopted by the present invention to solve technical problems is:

[0040] The method for preparing high-purity tantalum foil for OLED is characterized in that it comprises the following steps:

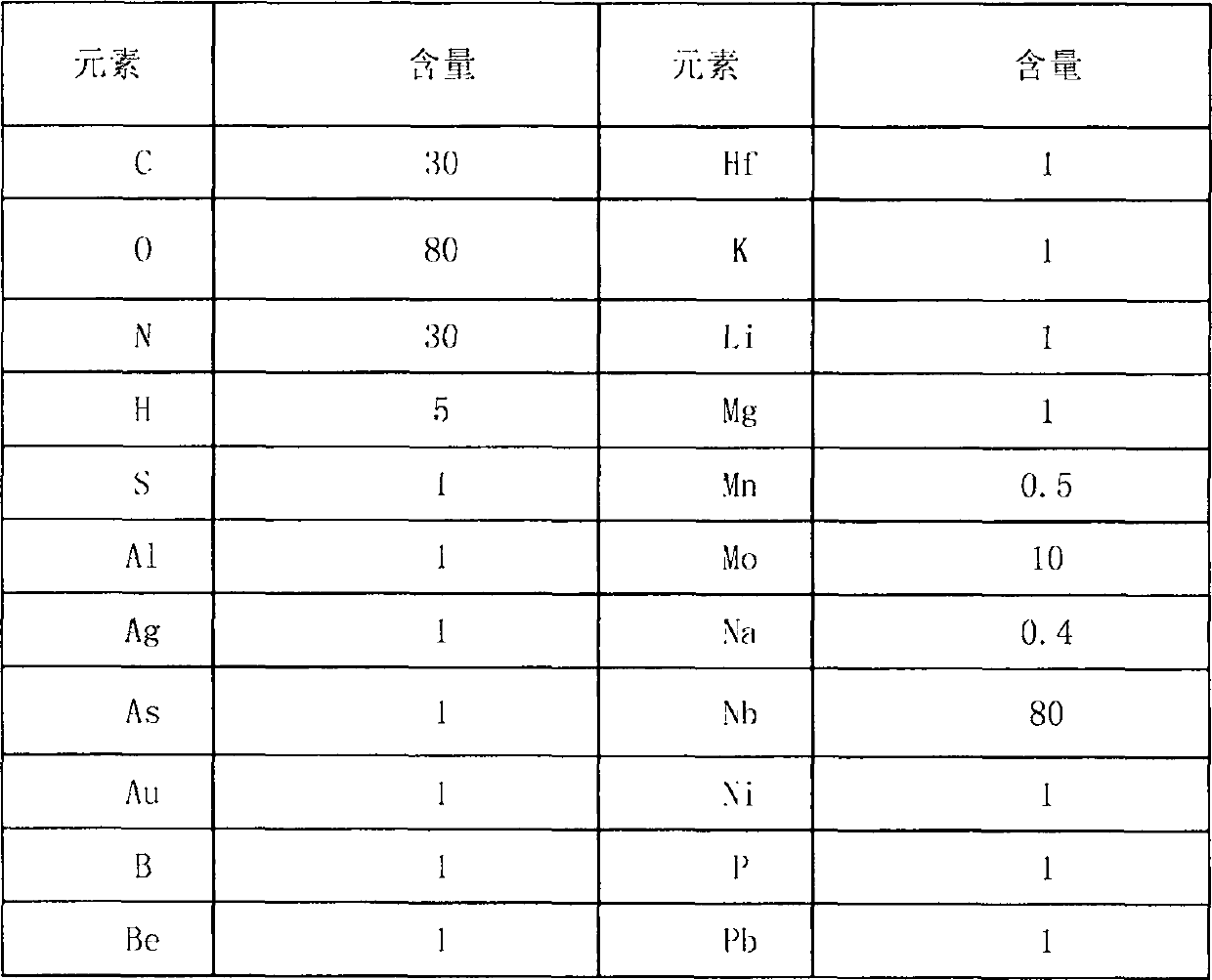

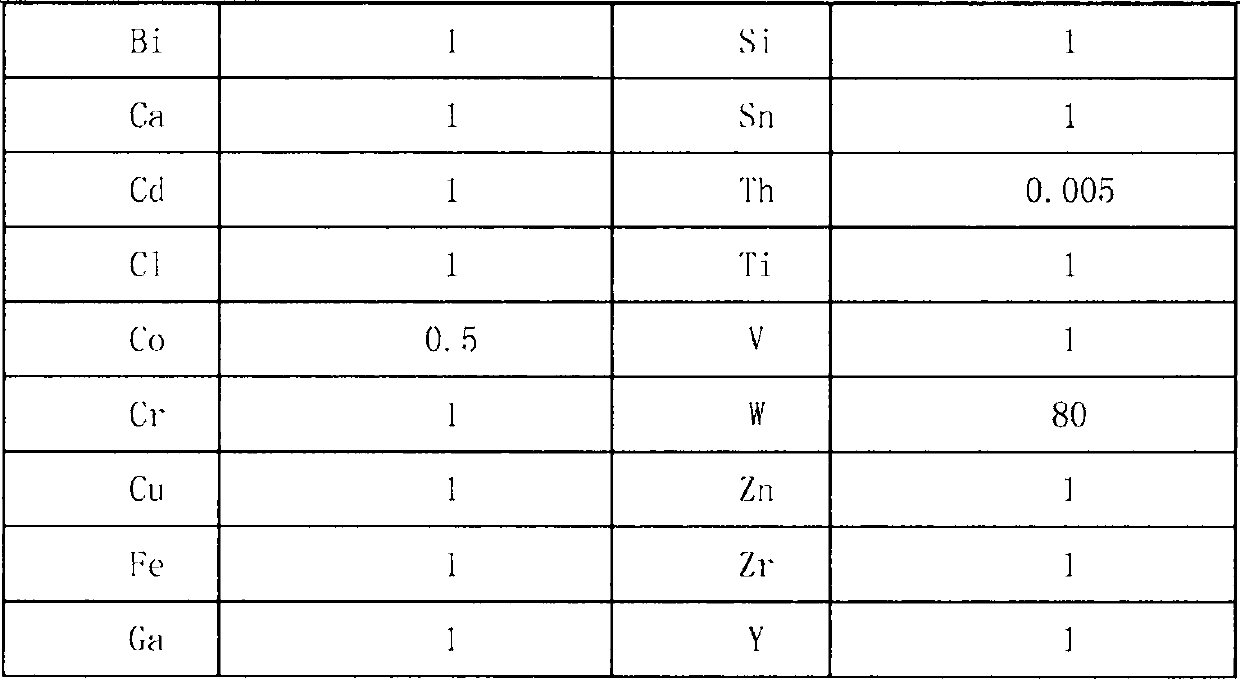

[0041] Step 1: Prepare materials: select tantalum bars with low niobium and tungsten content and purity ≥ 99.8%;

[0042]Step 2 Furnace loading: clean the furnace, ensure that there are no debris in the vacuum chamber, clean the reactor, avoid pollution, maintain a high-purity environment, and load the furnace with tantalum strips;

[0043] Step 3: Primary smelting: use electron beam furnace for smelting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com