Preparation technique of composite film electrode used for a super capacitor

A technology of supercapacitors and composite films, applied in the direction of capacitor electrodes, capacitor parts, etc., can solve the problems of application limitation and high price, and achieve the effects of high specific capacity, easy operation and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

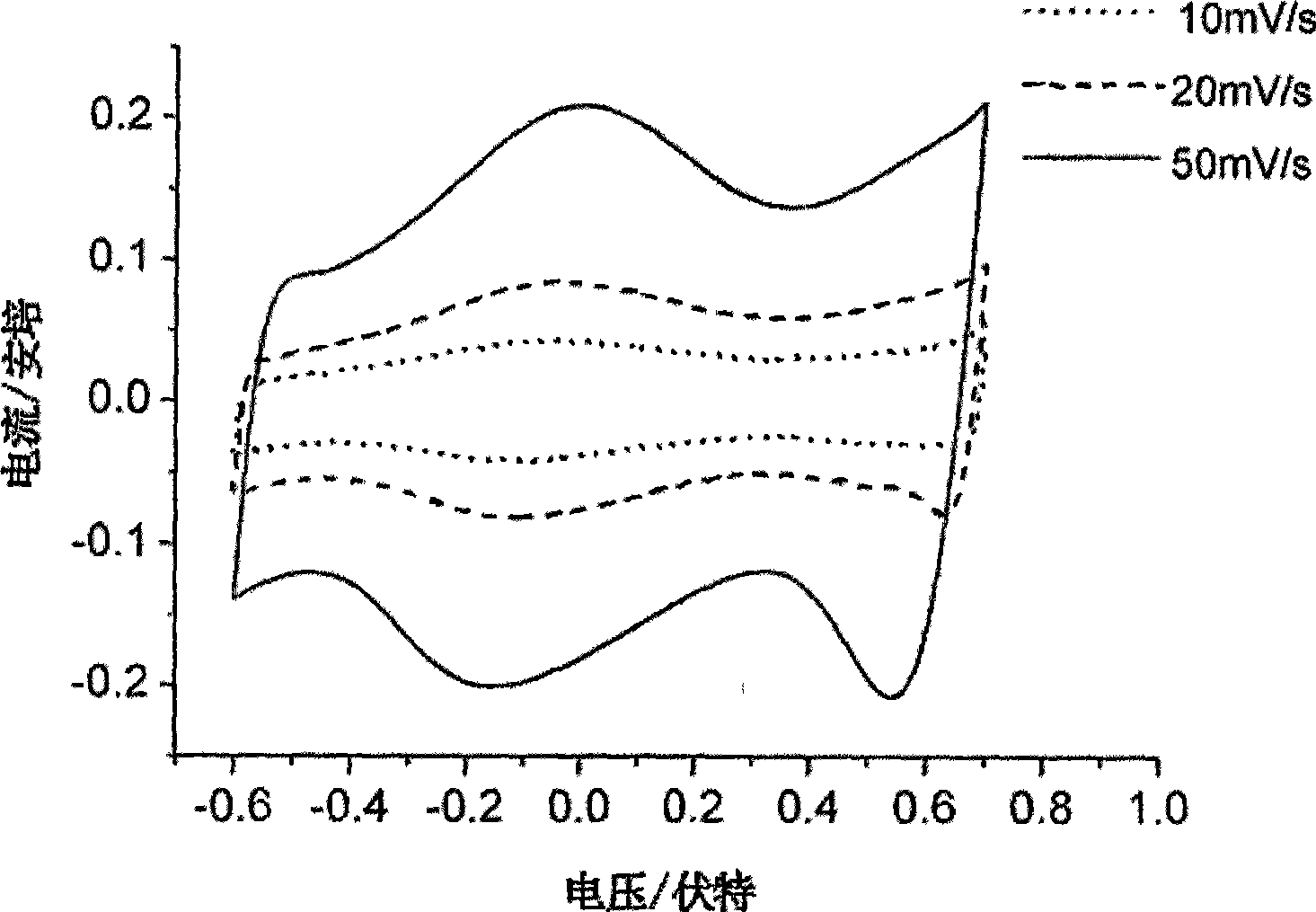

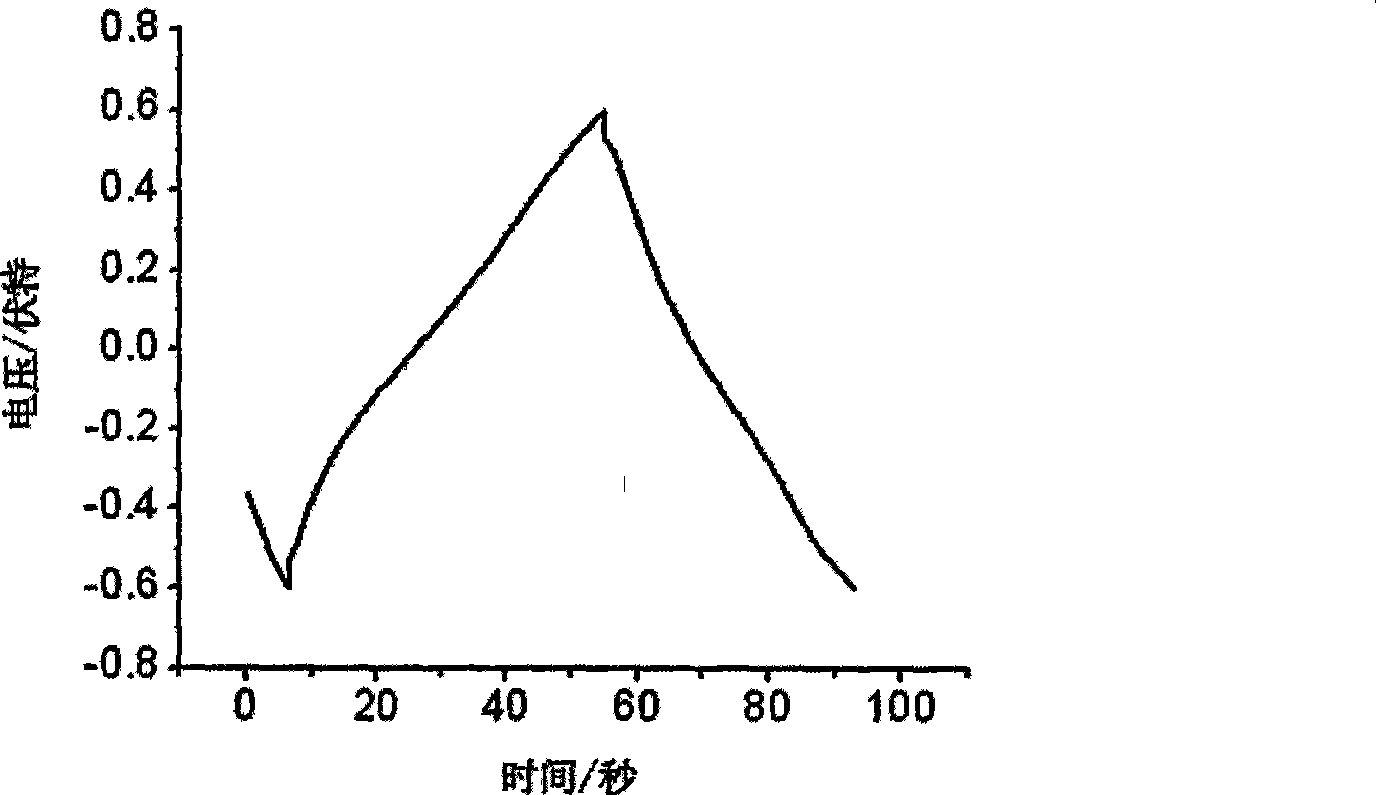

Image

Examples

Embodiment 1

[0028] ①Pretreatment process: First, use 400# metallographic sandpaper for roughening treatment, 800# metallographic sandpaper for grinding and polishing, then wash with acetone for 5-10 minutes; use phosphoric acid 40g / L, sodium hydroxide 5g / L, sodium silicate 20g / L and sodium carbonate 10g / L is heated and soaked for 10-15min, at 100mA / cm 2 , 70 ~ 80 ℃ cathodic electrolytic degreasing; hot washing in 20mL of hydrofluoric acid with a concentration of 40%, 10mL of nitric acid with a concentration of 1.4g / mL and 15mL of sulfuric acid with a concentration of 1.84g / mL, and then degreasing After cleaning with ion water, it is ready to use. During the cleaning process, ultrasonic cleaning is used to assist cleaning.

[0029] ② Configure electrodeposition solution, RuCl 3 2H 2 The concentration of O is fixed at 5mmol / L, and the SnCl 2 2H 2 The concentration of O depends on the Sn in the solution 2+ with Ru 3+ The molar concentration ratio is 1:1, the HCl and SnCl added in the ...

Embodiment 2

[0034] ①Pretreatment process: First, use 400# metallographic sandpaper for roughening treatment, 800# metallographic sandpaper for grinding and polishing, then wash with acetone for 5-10 minutes; use phosphoric acid 40g / L, sodium hydroxide 5g / L, sodium silicate 20g / L and sodium carbonate 10g / L is heated and soaked for 10-15min, at 100mA / cm 2 , 70 ~ 80 ℃ cathodic electrolytic degreasing; hot washing in 20mL of hydrofluoric acid with a concentration of 40%, 10mL of nitric acid with a concentration of 1.4g / mL and 15mL of sulfuric acid with a concentration of 1.84g / mL, and then degreasing After cleaning with ion water, it is ready to use. During the cleaning process, ultrasonic cleaning is used to assist cleaning.

[0035] ② Configure electrodeposition solution, RuCl 3 2H 2 The concentration of O is fixed at 5mmol / L, and the SnCl 2 2H 2 The concentration of O depends on the Sn in the solution 2+ with Ru 3+ The molar concentration ratio is 2:1, the HCl and SnCl added in the ...

Embodiment 3

[0040] ①Pretreatment process: First, use 400# metallographic sandpaper for roughening treatment, 800# metallographic sandpaper for grinding and polishing, then wash with acetone for 5-10 minutes; use phosphoric acid 40g / L, sodium hydroxide 5g / L, sodium silicate 20g / L and sodium carbonate 10g / L is heated and soaked for 10-15min, at 100mA / cm 2 , 70 ~ 80 ℃ cathodic electrolytic degreasing; hot washing in 20mL of hydrofluoric acid with a concentration of 40%, 10mL of nitric acid with a concentration of 1.4g / mL and 15mL of sulfuric acid with a concentration of 1.84g / mL, and then degreasing After cleaning with ion water, it is ready to use. During the cleaning process, ultrasonic cleaning is used to assist cleaning.

[0041] ② Configure electrodeposition solution, RuCl 3 2H 2 The concentration of O is fixed at 5mmol / L, and the SnCl 2 2H 2 The concentration of O depends on the Sn in the solution 2+ with Ru 3+ The molar concentration ratio, the preparation ratio is 3:1, the HCl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com