A kind of preparation method of high catalytic activity electrocatalyst 1t' phase tungsten sulfide

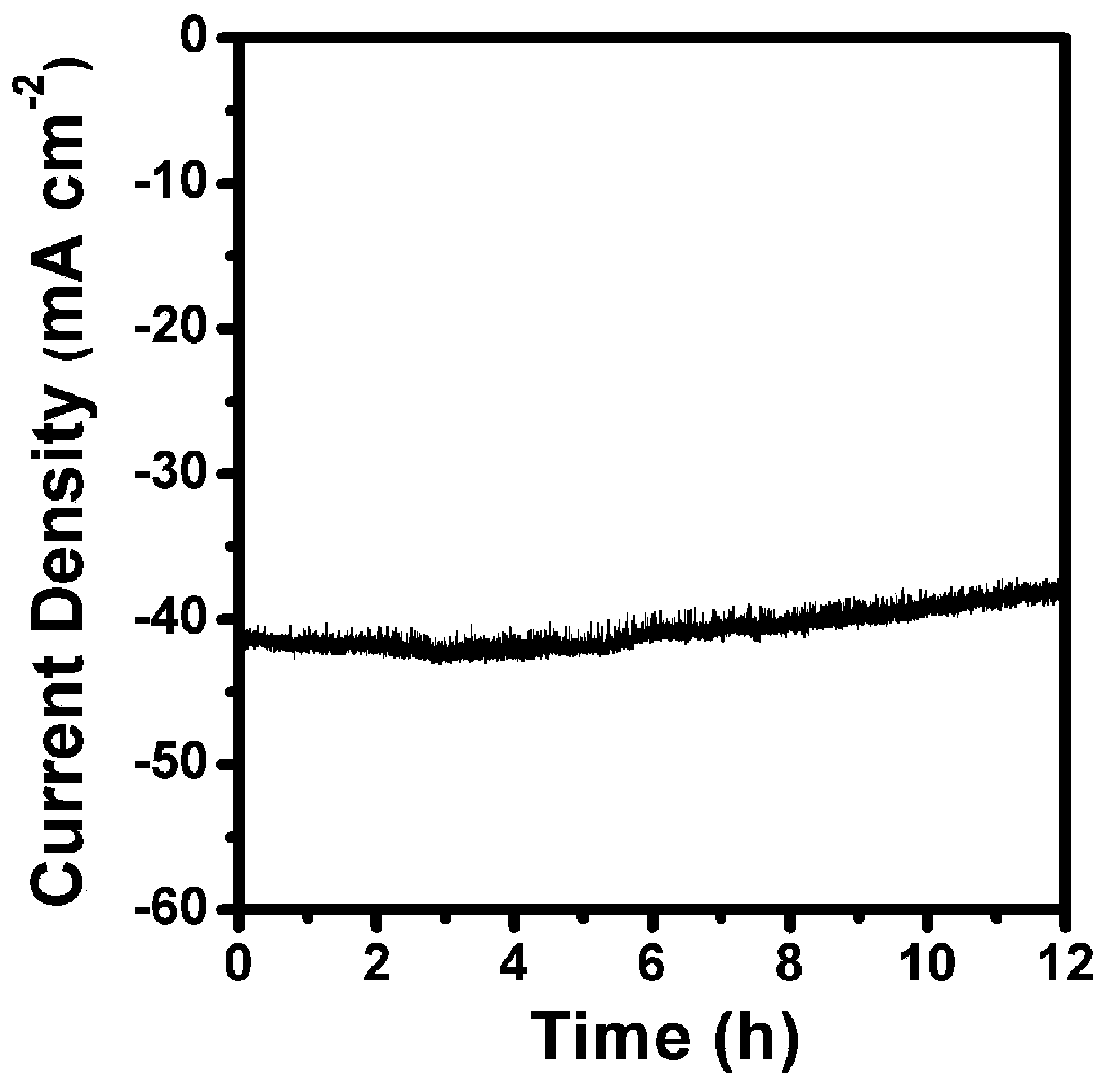

A high catalytic activity, electrocatalyst technology, applied in the field of material chemistry, can solve the problems of limited later application, and achieve the effect of uniform size, small Tafel slope, and multiple catalytic active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

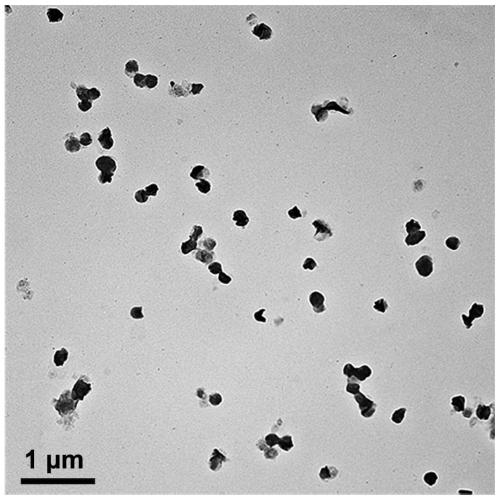

[0018] Dissolve 0.2mmol of ammonium tungstate and 0.6mmol of thiourea in 20mmol of high boiling point solvent octadecylamine, heat to 100°C under the protection of nitrogen until the solution turns light yellow, and then react at 280°C for 60 Minutes, after natural cooling to room temperature, add 50mL of ethanol, filter to obtain a filter cake, wash and dry the filter cake to obtain a black powder with a size of 160nm, which is the high catalytic activity electrocatalyst 1T'phase tungsten sulfide.

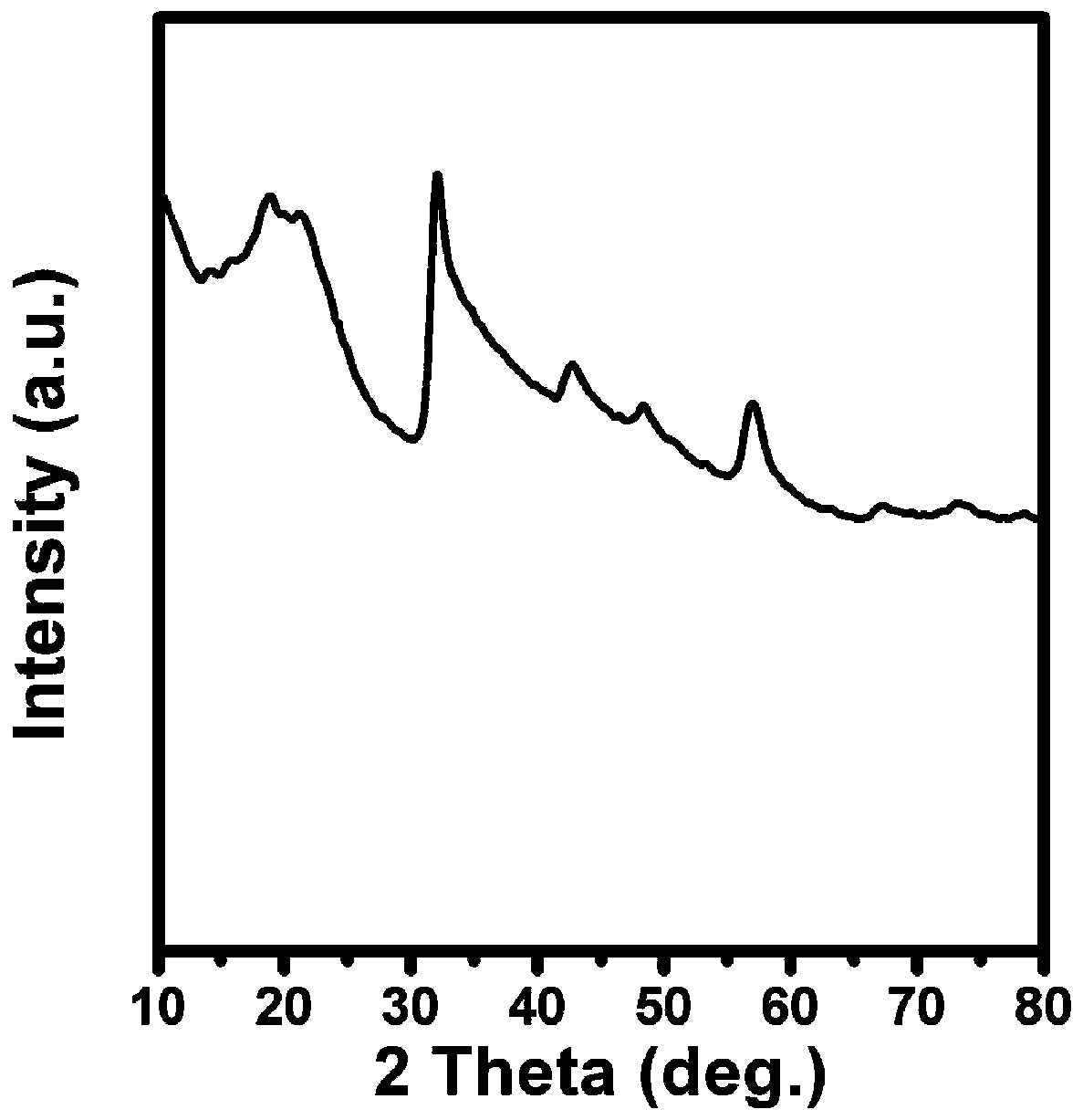

[0019] see figure 1 , the prepared product was identified as metallic 1T' phase WS by powder X-ray diffraction 2 .

[0020] see figure 2 , the product was observed by transmission electron microscopy as spherical nanoparticles with a size of 160nm.

Embodiment 2

[0022] Dissolve 0.2mmol of ammonium tungstate and 0.6mmol of thiourea in 10mmol of high boiling point solvent hexadecylamine, heat to 120°C under the protection of nitrogen until the solution turns light yellow, and then react at 300°C for 90 Minutes, after natural cooling to room temperature, add 50mL of ethanol, filter to obtain a filter cake, wash and dry the filter cake to obtain high catalytic activity electrocatalyst 1T'phase tungsten sulfide.

Embodiment 3

[0024] Dissolve 0.2mmol of ammonium tungstate and 0.6mmol of thiourea in 20mmol of a mixed solvent of high boiling point solvent dodecane and oleylamine, heat to 120°C under the protection of nitrogen until the solution turns light yellow, and then at 300 React at ℃ for 60 minutes, cool to room temperature naturally, add 50mL of ethanol, filter to obtain a filter cake, wash and dry the filter cake to obtain high catalytic activity electrocatalyst 1T'phase tungsten sulfide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com