Nickel-molybdenum-copper ternary metal phosphide as well as preparation method and application thereof

A ternary metal and phosphide technology, applied in the direction of phosphides, phosphorus compounds, chemical instruments and methods, etc., can solve the problems of unpopularity, high cost, and low reserves, etc., and achieve excellent stability, low cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

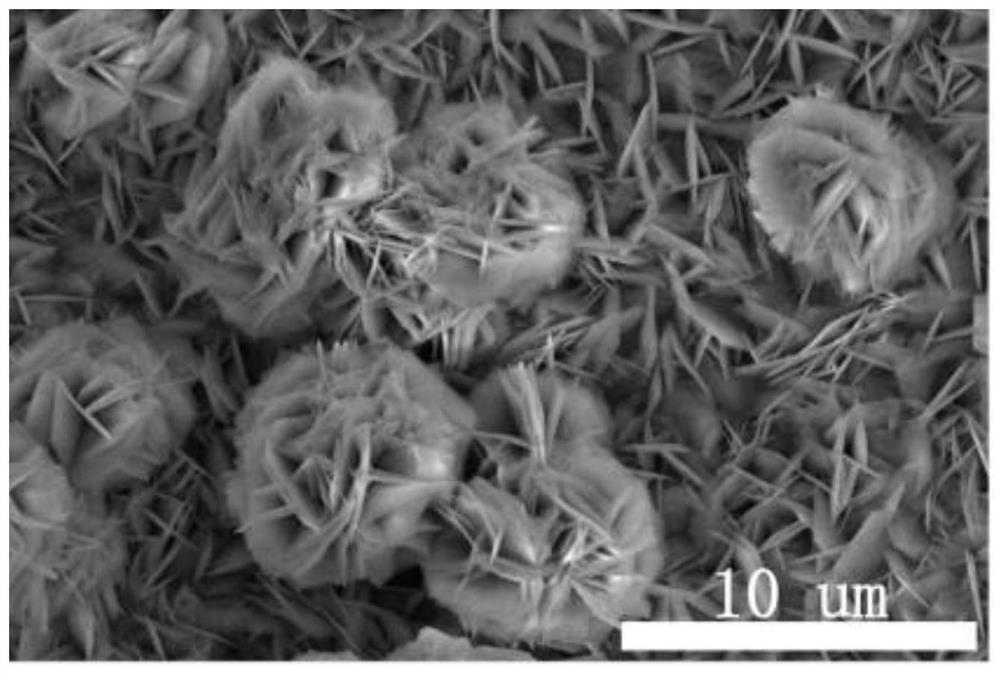

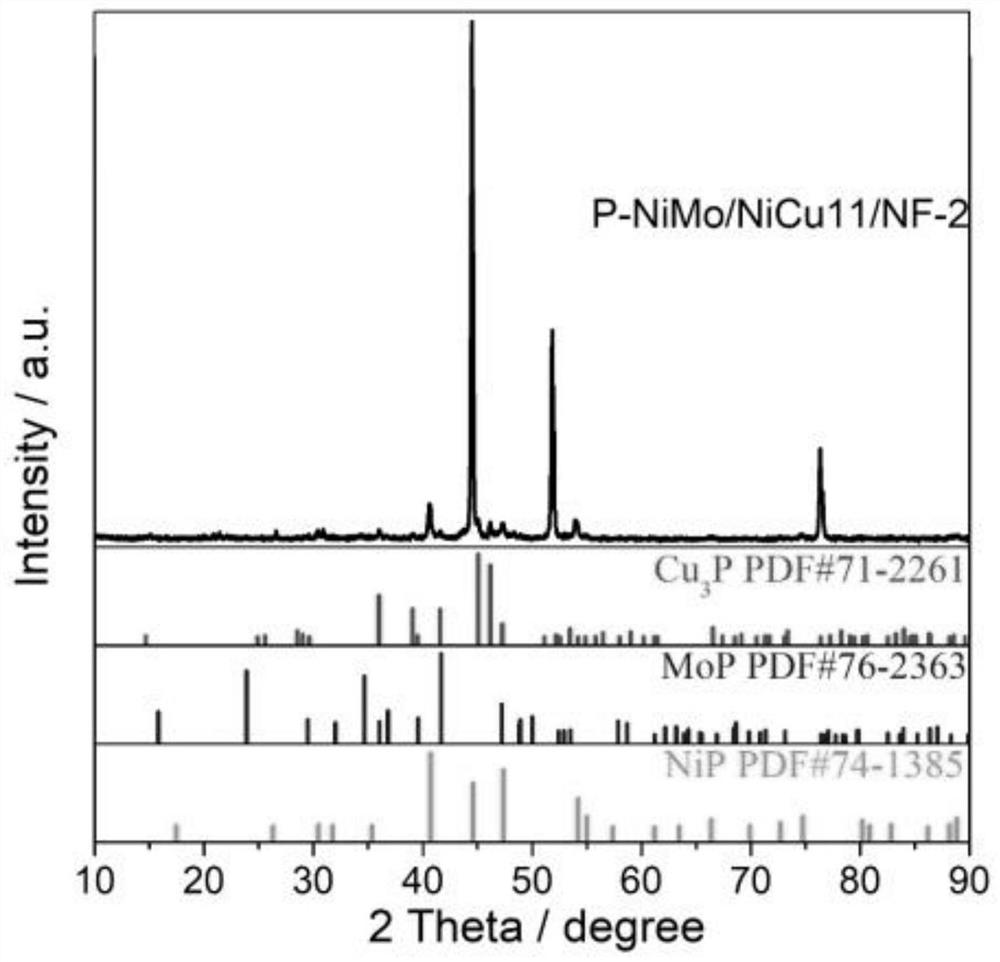

[0034] In this embodiment, a method for preparing a nickel-molybdenum-copper ternary metal phosphide comprises the following steps:

[0035] (1) Put nickel foam with a size of 20mm×30mm into 20mL of acetone and ultrasonically clean it for 10 minutes, then ultrasonically wash it with 20mL of 3M hydrochloric acid for 10 minutes; then use ultrapure water and absolute ethanol to clean the surface successively. The foamed nickel is placed in an oven at 60°C until dry;

[0036] (2) 8mmol urea, 6mmol NH 4 F, 1mmol Ni(NO 3 ) 2 ·6H 2 O and 1mmol Cu(NO 3 ) 2 ·3H 2 O was dissolved in 30mL deionized water; a mixed solution was obtained; the mixed solution and the nickel foam obtained in the step (1) were moved into a 50mL reaction kettle, dried in a drying oven, and kept at 120°C for 6 hours ; Then the dried material was washed three times with deionized water and ethanol respectively, and the obtained clean material was dried in a vacuum oven at 60° C. for 12 hours;

[0037] (3) ...

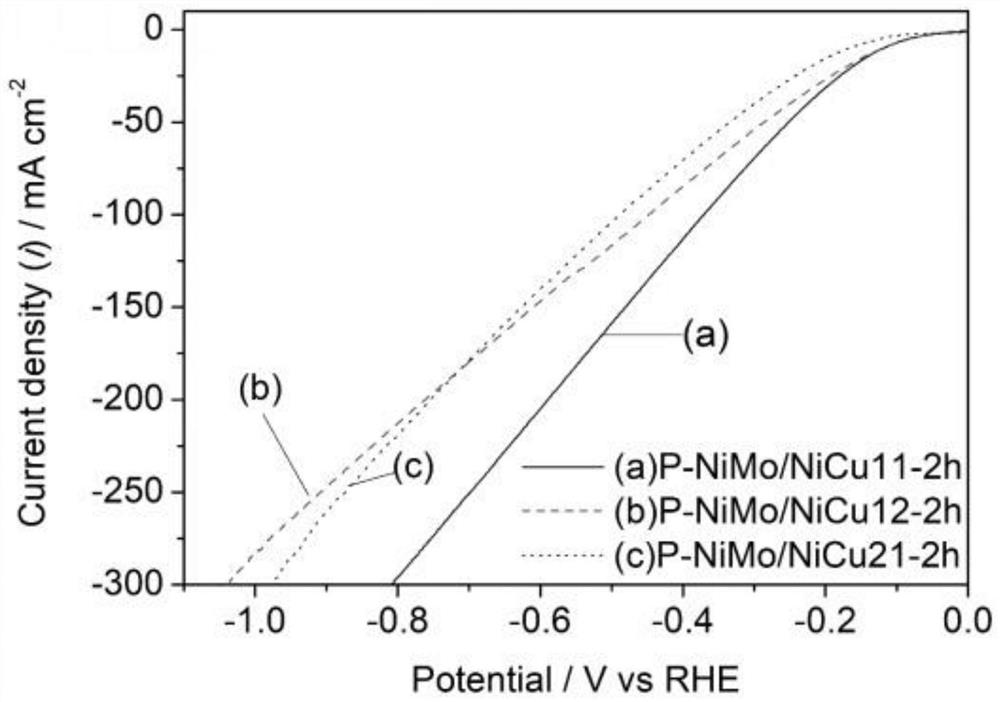

Embodiment 2

[0040] This embodiment is basically the same as Embodiment 1, especially in that:

[0041] In this embodiment, a method for preparing a nickel-molybdenum-copper ternary metal phosphide comprises the following steps:

[0042] (1) Put nickel foam with a size of 20mm×30mm into 20mL of acetone and ultrasonically clean it for 10 minutes, then ultrasonically wash it with 20mL of 3M hydrochloric acid for 10 minutes; then use ultrapure water and absolute ethanol to clean the surface successively. The foamed nickel is placed in an oven at 60°C until dry;

[0043] (2) 8mmol urea, 6mmol NH 4 F, 0.67mmol Ni(NO 3 ) 2 ·6H 2 O and 1.33mmol Cu(NO 3 ) 2 ·3H 2 O was dissolved in 30mL deionized water; a mixed solution was obtained; the mixed solution and the nickel foam obtained in the step (1) were moved into a 50mL reaction kettle, dried in a drying oven, and kept at 120°C for 6 hours ; Then the dried material was washed three times with deionized water and ethanol respectively, and the ...

Embodiment 3

[0047] This embodiment is basically the same as the above-mentioned embodiment, and the special features are:

[0048] In this embodiment, a method for preparing a nickel-molybdenum-copper ternary metal phosphide comprises the following steps:

[0049] (1) Put nickel foam with a size of 20mm×30mm into 20mL of acetone and ultrasonically clean it for 10 minutes, then ultrasonically wash it with 20mL of 3M hydrochloric acid for 10 minutes; then use ultrapure water and absolute ethanol to clean the surface successively. The foamed nickel is placed in an oven at 60°C until dry;

[0050] (2) 8mmol urea, 6mmol NH 4 F, 1.33mmol Ni(NO 3 ) 2 ·6H 2 O and 0.67mmol Cu(NO 3 ) 2 ·3H 2 O was dissolved in 30mL deionized water; a mixed solution was obtained; the mixed solution and the nickel foam obtained in the step (1) were moved into a 50mL reaction kettle, dried in a drying oven, and kept at 120°C for 6 hours ; Then the dried material was washed three times with deionized water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com