Manufacturing method for applying soft and hard combined plate to adaptor connector

A soft-rigid combination board and transfer connector technology, which is applied in the direction of connection, connection/disconnection of connecting device, circuit/collector parts, etc. Can not be plugged in, occupying space and other problems, to avoid external signal intrusion to interfere with signal transmission, stable signal transmission, and prevent electromagnetic wave leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to achieve the above-mentioned purpose and effect, the technical means and the structure adopted by the present invention are hereby illustrated in detail with respect to the preferred embodiments of the present invention. The features and functions are as follows for a complete understanding.

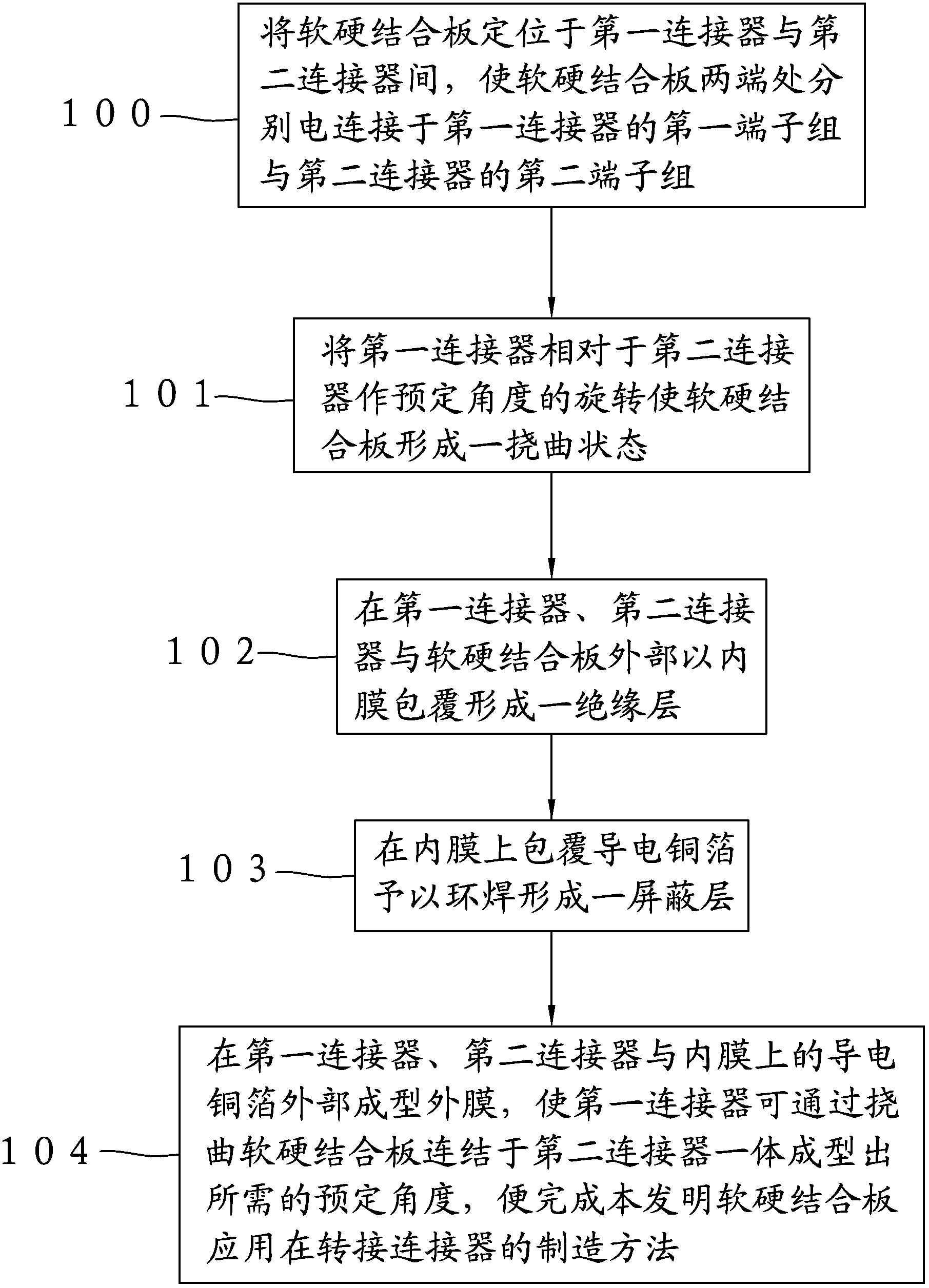

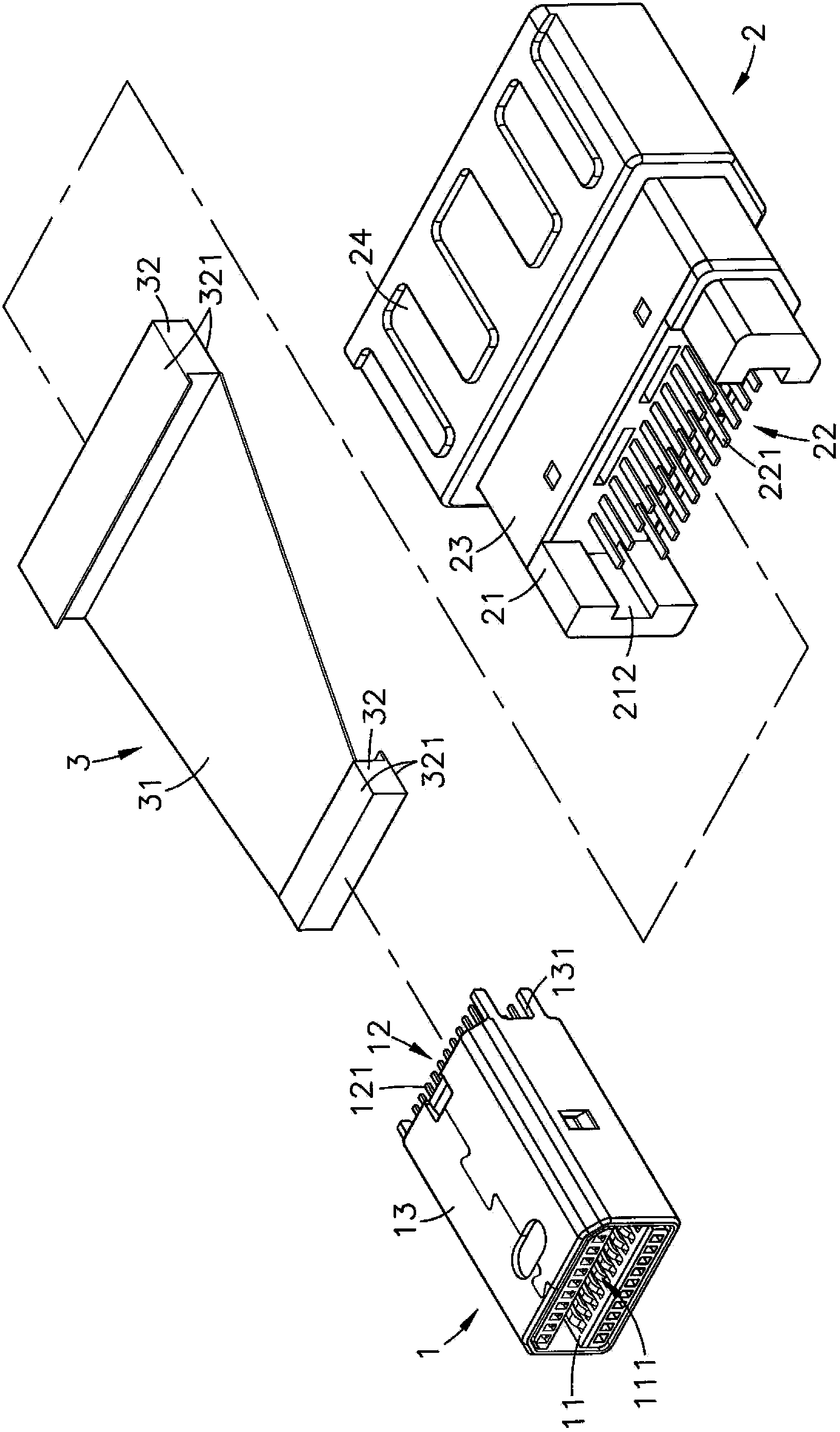

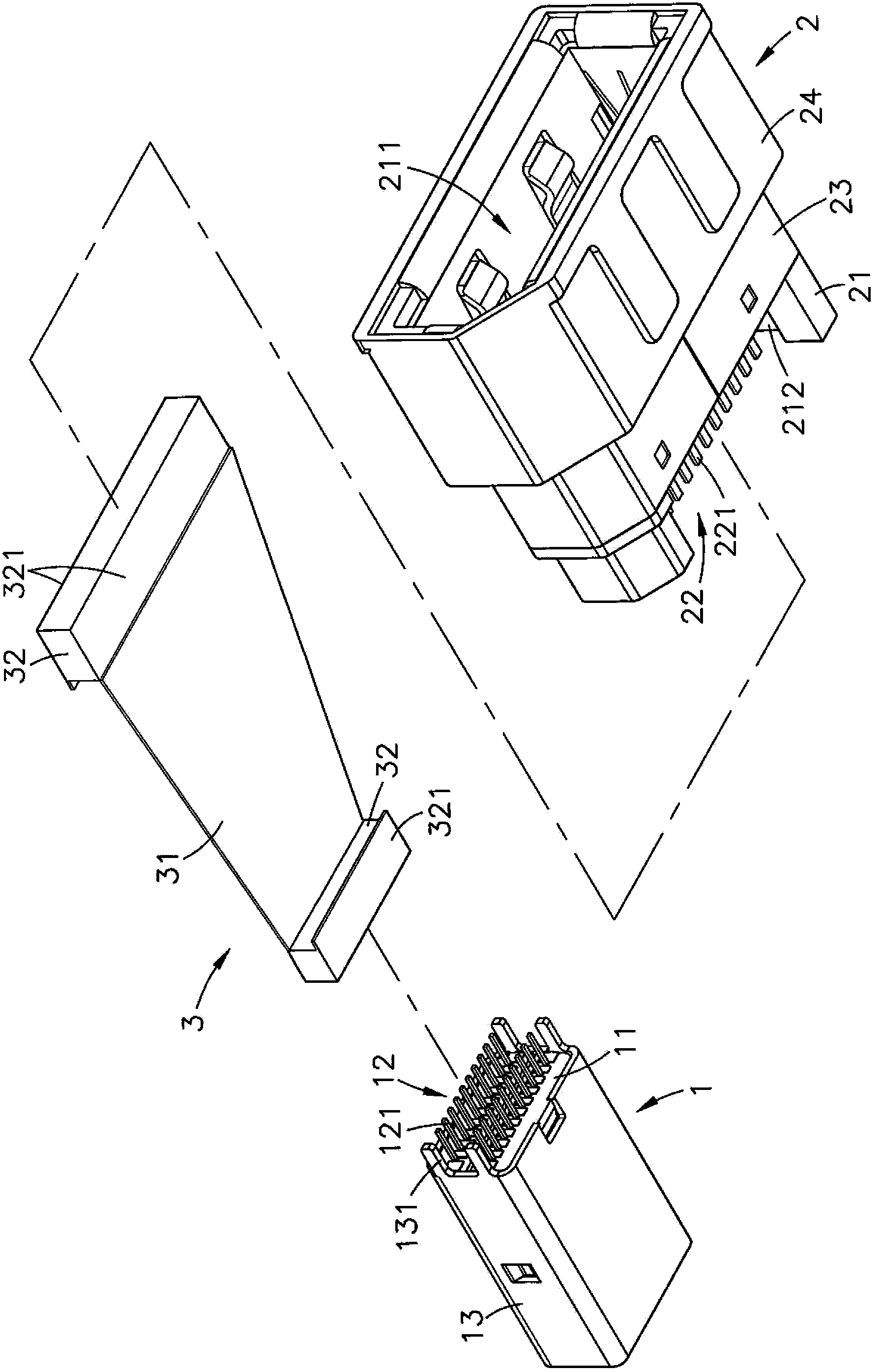

[0035] seefigure 1 , figure 2 , image 3 , Figure 4 As shown, they are the manufacturing flow chart of the present invention, the perspective exploded view of the first connector, the second connector and the rigid-flex board before assembly, the perspective exploded view of another perspective before assembly, and the perspective appearance view after assembly , it can be clearly seen from the figure that the present invention includes a first connector 1, a second connector 2 and a rigid-flex board 3, wherein:

[0036] The first connector 1 has a base 11, and on one side of the base 11 is provided with a first docking portion 111 and a first terminal group 12 arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com