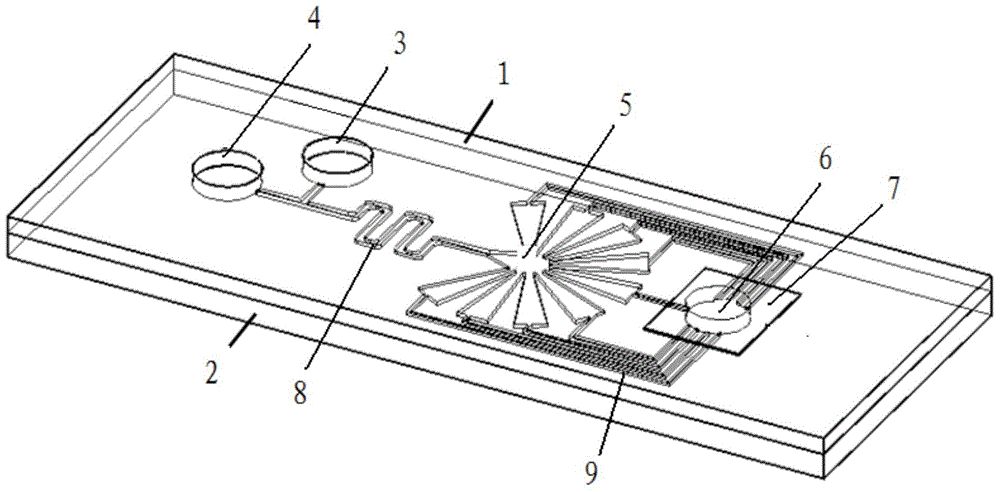

Portable type micro-droplet generator based on self-powered vacuum micro pump

A technology of micro droplets and generators, which is applied in the directions of containers, laboratory utensils, chemical instruments and methods for laboratory use, can solve problems such as being unsuitable for portable analysis and detection, increase dead volume, etc., and achieve simple and easy assembly. Manipulate, avoid effects of flow connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

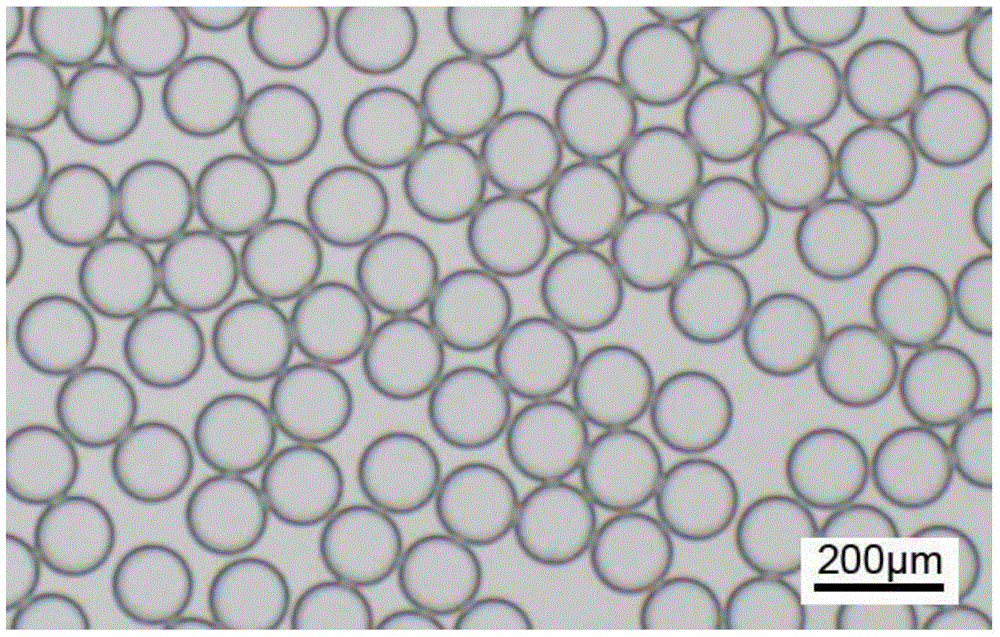

[0022] The production of the microstructure on the cover sheet 1 with microstructure is as follows: first use photo-etching technology to make SU-8 template, then cast polydimethylsiloxane on the template, polymerize in an oven at 80°C for 2 hours, and finally The polymer imprinted with the microstructure is peeled from the mold. The flat substrate 2 is flat glass, and the cover sheet 1 and the flat substrate 2 with microstructures are treated with oxygen plasma and sealed together to form a microfluidic channel. Place the sealed chip in an oven at 80°C overnight to restore the hydrophobicity of the polydimethylsiloxane. Place the micro-droplet generator in a vacuum desiccator for degassing before use, and then quickly add the water phase solution and oil phase solution drops to the micro-droplet generator from the water phase solution inlet 3 and the oil phase solution inlet 4 respectively. Inside. Under the action of the negative pressure in the liquid microchannel 8 and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com