Insulating skeleton, stator assembly, motor

A technology of insulating frame and frame, which is applied in the fields of motors, insulating frames, and stator components. It can solve problems such as loose connection of circuit boards, increased material costs, and increased motor height. It achieves reduced manufacturing costs, simple and compact structure, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

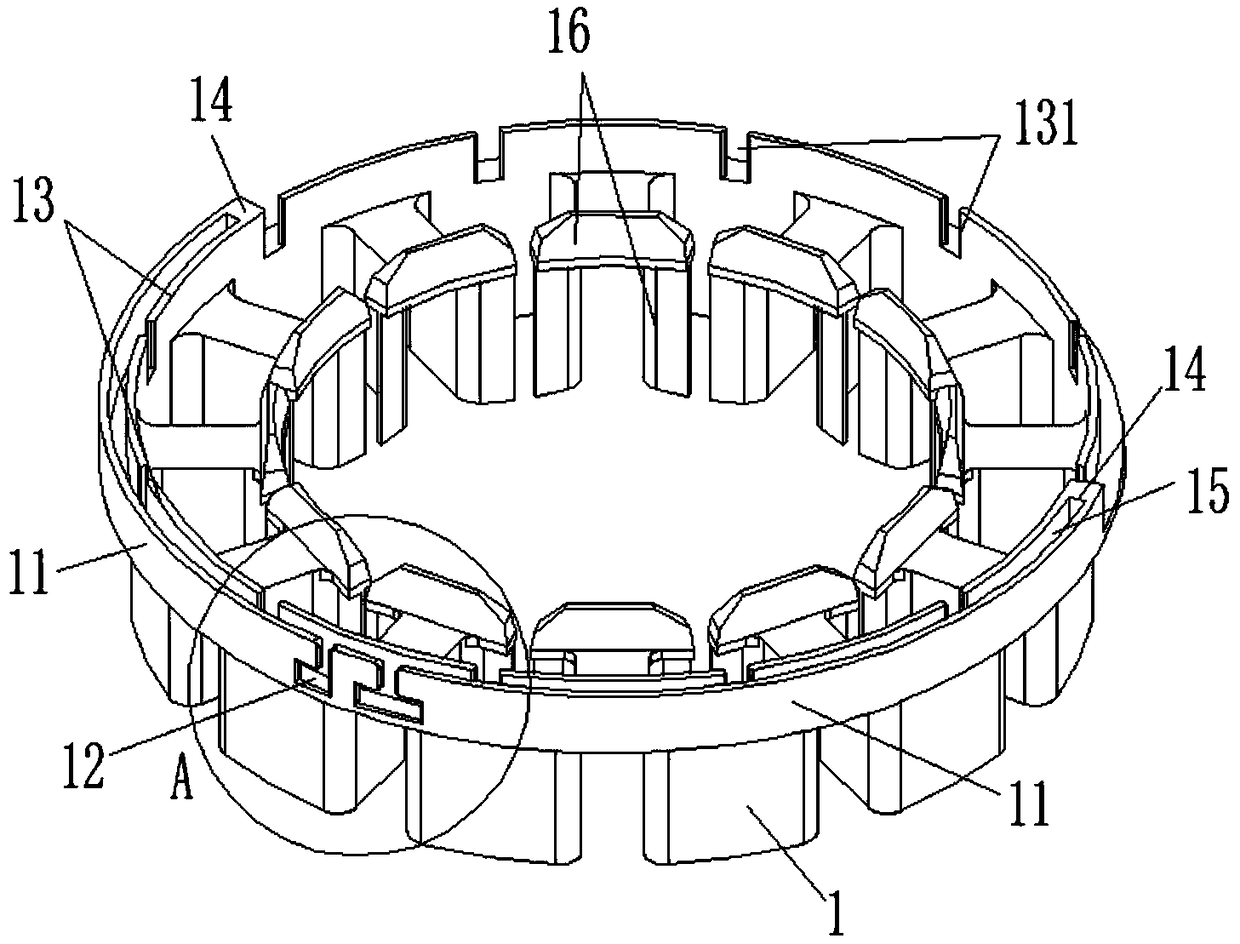

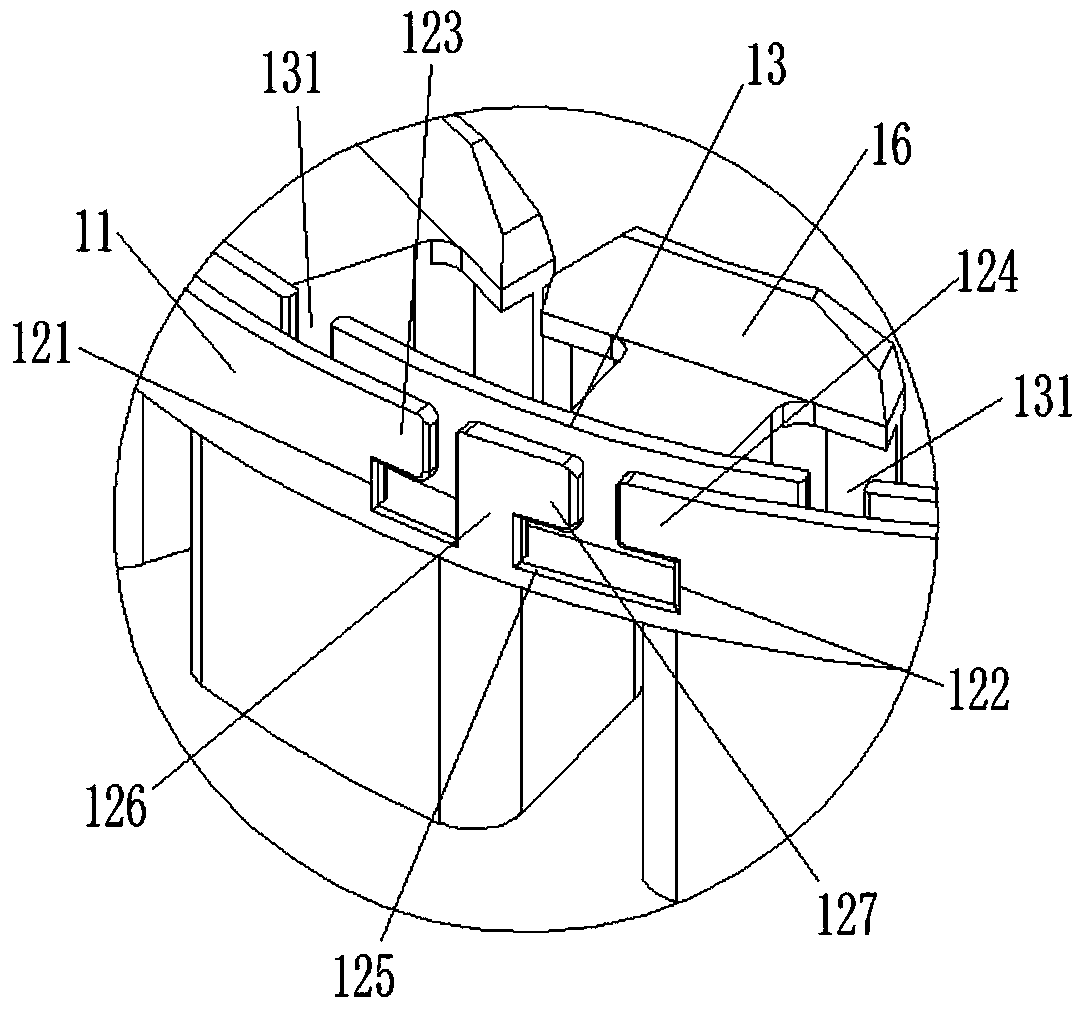

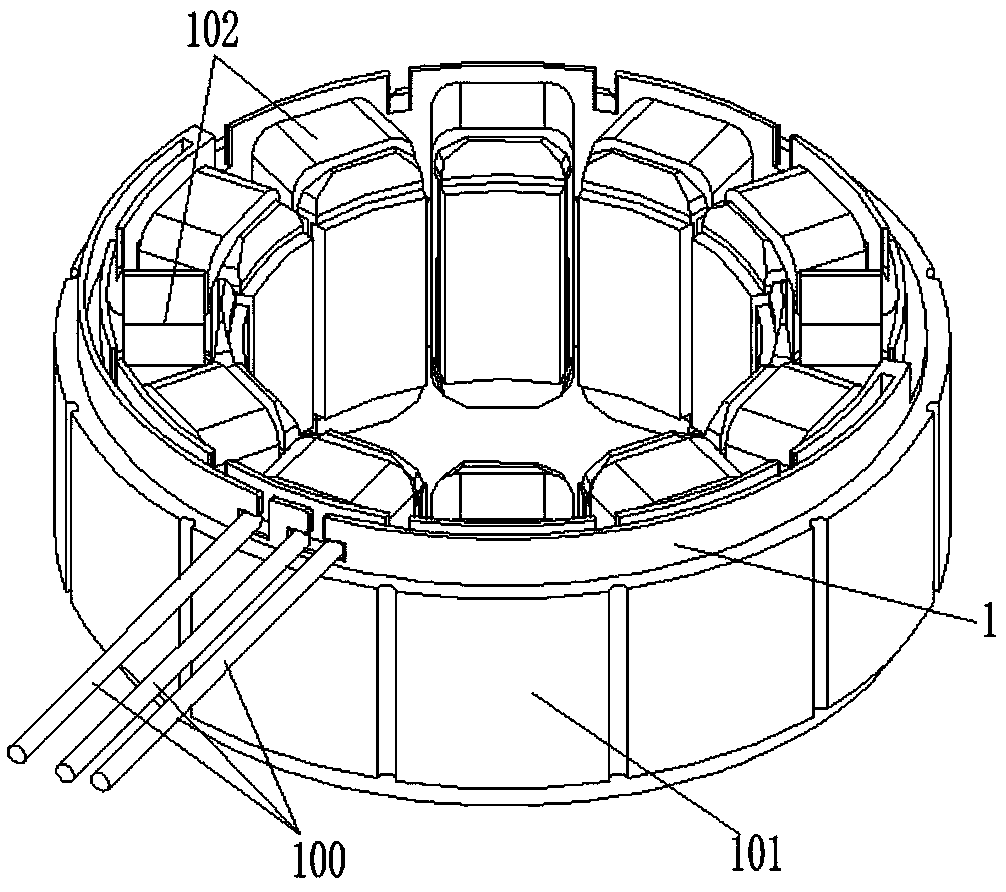

[0023] see in conjunction Figure 1 to Figure 3 As shown, according to the embodiment of the present invention, an insulating frame is provided, including a frame body 1, an outer ring wall 11 extending axially along the end surface of the frame body 1 is configured, and the outer ring wall 11 has a The limiting groove 12 limits the power cord 100 . In this technical solution, a limit groove 12 is set on the outer ring wall 11 to limit the power cord 100, so that the structure of the motor becomes simpler and more compact, the size is smaller, the manufacturing cost of the motor is reduced, and the power cord is effectively avoided. , Loose connection between winding lead wires, winding disconnection and other quality problems. The limiting groove 12 can be, for example, a groove with a constriction structure. It can be understood that the size of the limiting groove 12 should match the wire diameter of the power cord 100, and it is best to be able to A transition or even an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com