Glue dispensing device of hollow cup motor rotor

A motor rotor and glue dispensing device technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of occupying the operator's operating time, restricting the manufacturing cost of the hollow cup motor, and unstable dispensing quality. Achieve the effect of precise automatic dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

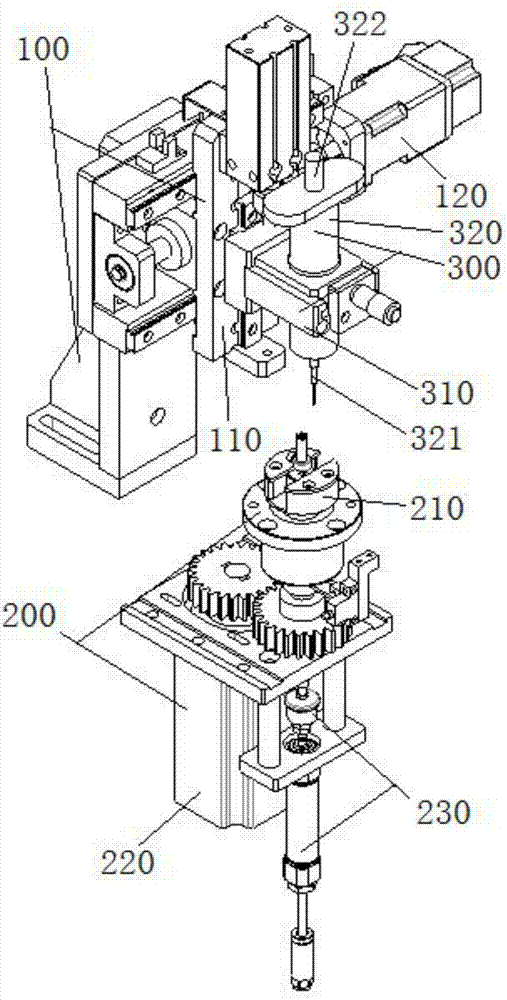

[0034] Such as figure 2 As shown, the present invention provides a coreless motor rotor dispensing device, comprising: a servo translation mechanism 100, a coreless motor rotor rotation mechanism 200 and an automatic dispensing device 300; the servo translation mechanism is provided with a moving slider 110 and Servo driving device 120, the moving slider 110 has a degree of freedom of movement in the horizontal direction and / or vertical direction under the action of the servo driving device 120; the automatic dispensing device 300 is fixed on the moving On the slider 110, the automatic dispensing device 300 includes: a rubber cartridge fixing device 310 and a glue cartridge 320 provided with a dispensing needle 321; the glue cartridge 320 is provided with a compressed air injection port 322; the glue cartridge is fixed The device 310 is firmly connected with the moving slider 110; the rubber tube 320 is fixed on the rubber tube fixing device 310; the coreless motor rotor rota...

Embodiment 2

[0038] On the basis of Embodiment 1, this embodiment also includes a compressed air source, the air outlet of the compressed air source is provided with a solenoid valve, and the gate valve is connected to the valve provided on the rubber cartridge through the pipeline provided with a pressure stabilizing valve. Compressed air injection port connection.

[0039] The invention configures an independent compressed air source for the hollow cup motor rotor dispensing device, so that the hollow cup motor rotor dispensing device does not depend on the arrangement position of the air source on the production line, and provides a strong structural support for independent work. Usually, the hollow cup motor The rotor automatic production line will be equipped with a compressed air source, and an independent compressed air source will be configured for the coreless motor rotor dispensing device, which will help to set the coreless motor rotor dispensing device at the processing position...

Embodiment 3

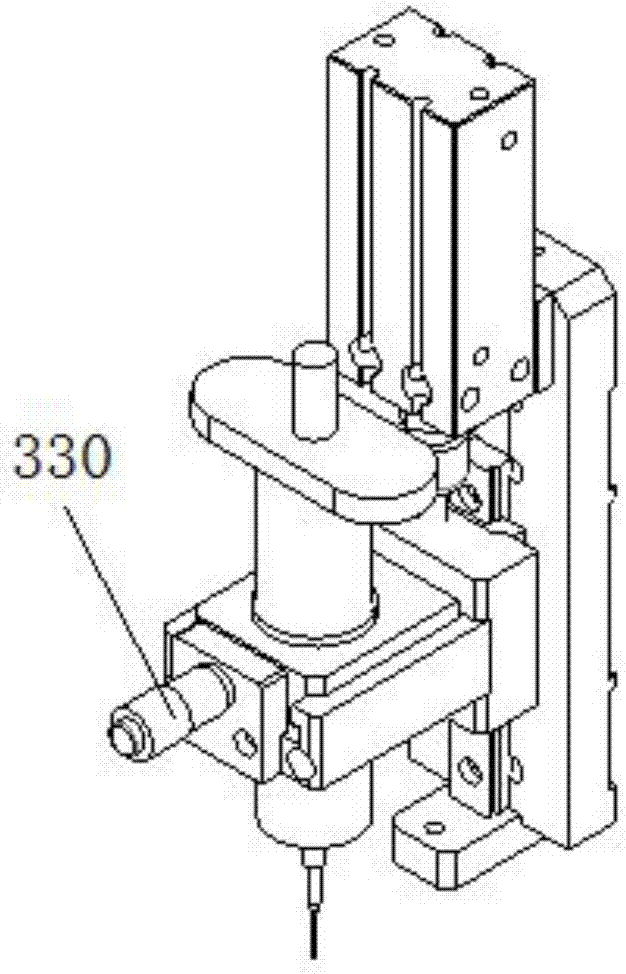

[0041] preferred, such as image 3 In the illustrated embodiment, on the basis of the above-mentioned embodiments, the rubber cartridge fixing device is provided with a rubber cartridge height fine-tuning device 330, and the rubber cartridge height fine-tuning device 330 can fine-tune the relative height of the rubber cartridge within the range of 3-5mm. at the height of the dispensing fixture.

[0042] The present invention further provides a fine adjustment device for the height of the rubber cylinder on the rubber cylinder fixing device, which helps to fine-tune the dispensing position of the dispensing needle after the coreless motor rotor dispensing device has been used for a period of time, and provides a strong structural support, which is convenient for timely adjustment of wear and tear The dispensing position of the rear dispensing needle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com