Vapor chamber and manufacturing method for the same

一种制造方法、均温板的技术,应用在热传导领域,能够解决困难等问题,达到增加冷却表面面积、避免变形或泄漏、提升回流速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

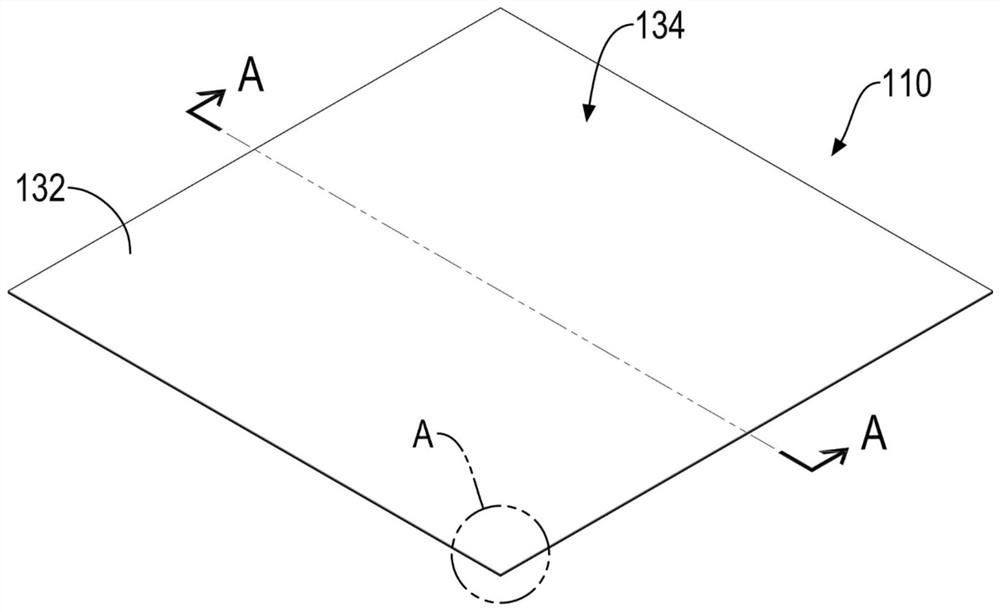

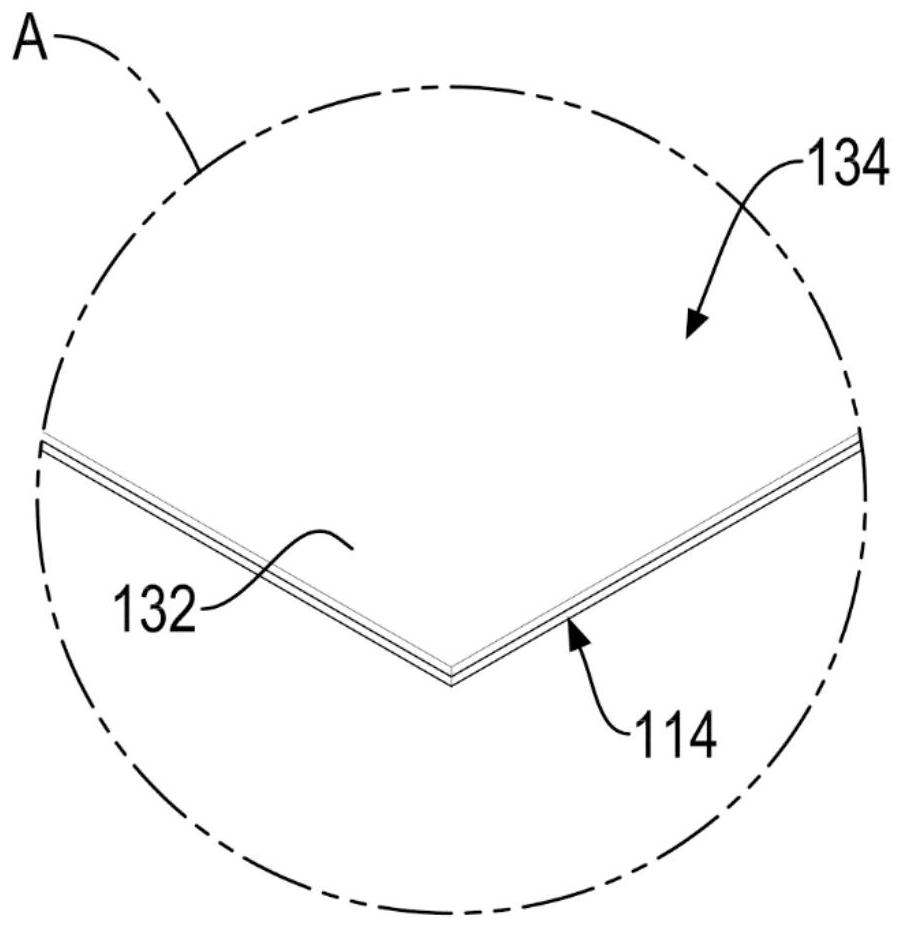

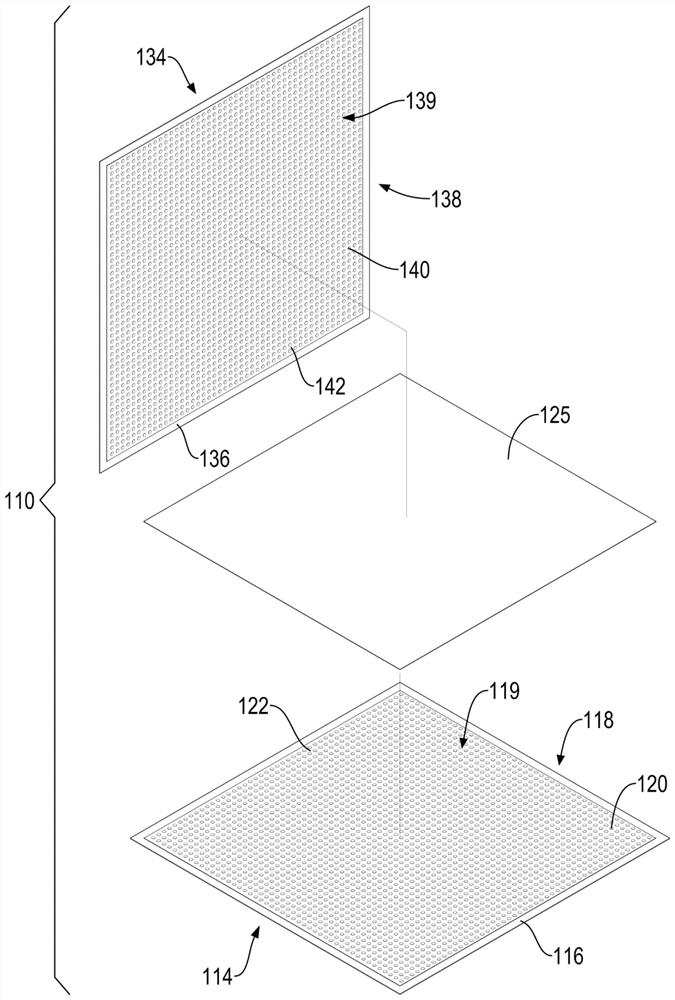

[0051] The present invention relates to a vapor chamber. Please refer to Fig. 1 to Fig. 3. It can be seen from the figures that the vapor chamber 110 of the present invention includes a top shell 134, a bottom shell 114 and a capillary structure 125. The top shell 134 and the bottom shell 114 have a first surface 132, 112 and a second surface 138, 118 respectively, wherein the first surface 132, 112 is used to thermally couple with the heat load of a heat source, such as the first surface 112 of the bottom shell 114 , and each second surface 138, 118 has a heat exchange area 139, 119 surrounded by an outer ring portion 136, 116, each heat exchange area 139, 119 includes a plurality of evaporation areas 142, 122 Separated surface features 140, 120, preferably, the top case 134 and the bottom case 114 are made of a heat-conducting material with relatively high heat-conducting efficiency, such as copper or aluminum, and the first surfaces 132, 112 thereof are a plane, It is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com