Honeycomb panel-type radiator

A radiator and honeycomb-shaped technology, applied in the field of cold and heat exchange devices, can solve the problems of low structural strength, weak heat dissipation ability, difficult to work, etc., and achieve the effect of good structural strength, simple structure and good structural support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

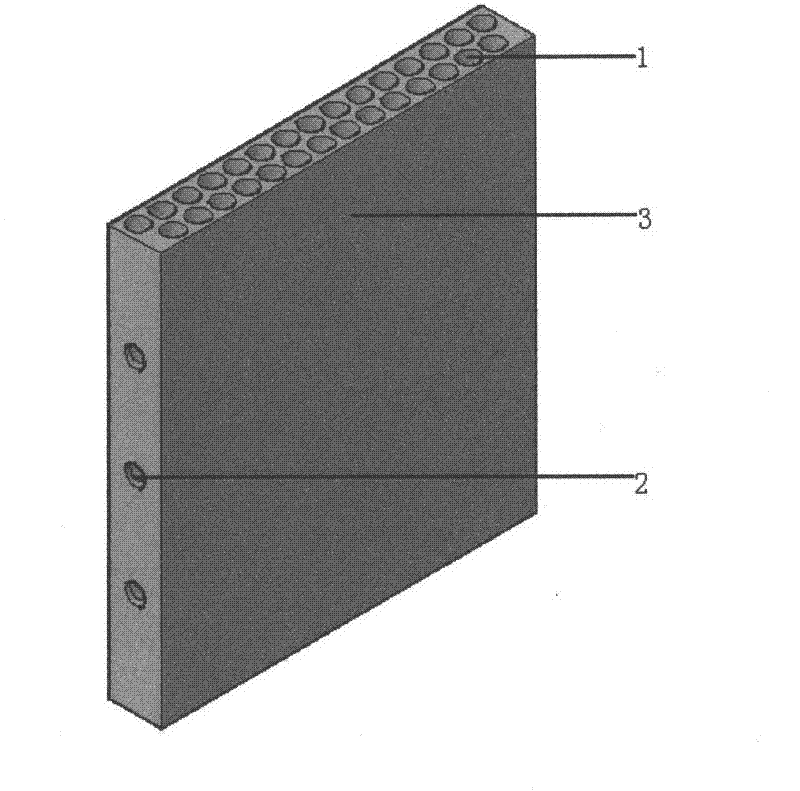

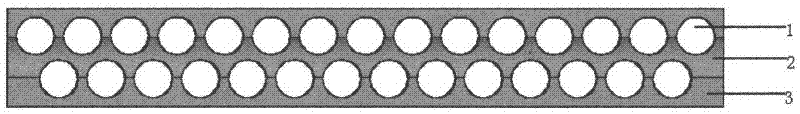

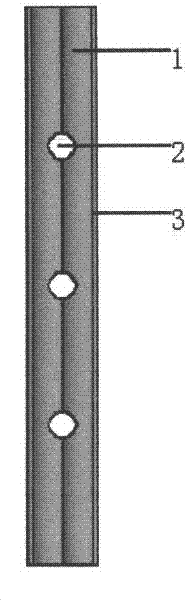

[0018] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Among them, after the radiator collects the heat, the temperature rises, and the heat conduction plate (3) evenly sends the heat to each longitudinal guide hole (1) of the radiator. Due to the temperature difference, the heat sink and the air in the longitudinal backflow hole (1) generate convection, and the convection in the relatively closed longitudinal flow guide hole (1) is continuously superimposed and enhanced, and the heat exchange efficiency is improved. While the convection in the longitudinal diversion hole (1) is enhanced, the horizontal flow supply hole (2) supplements the fluid in the longitudinal diversion hole (1). Since both the longitudinal guide holes (1) and the transverse flow supply holes (2) are in the shape of pipes, a large heat exchange area is generated and the external force borne by the radiator can be evenly sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com