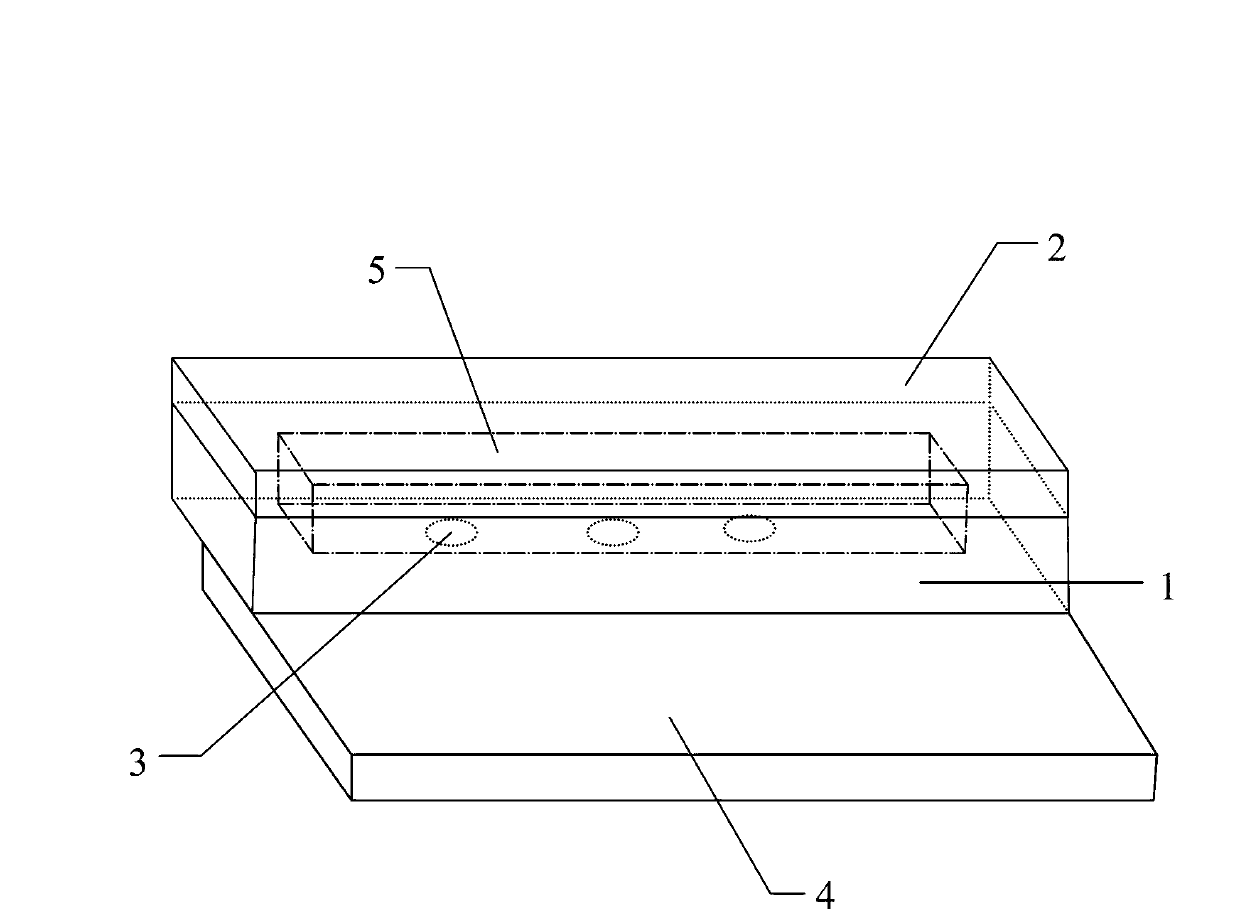

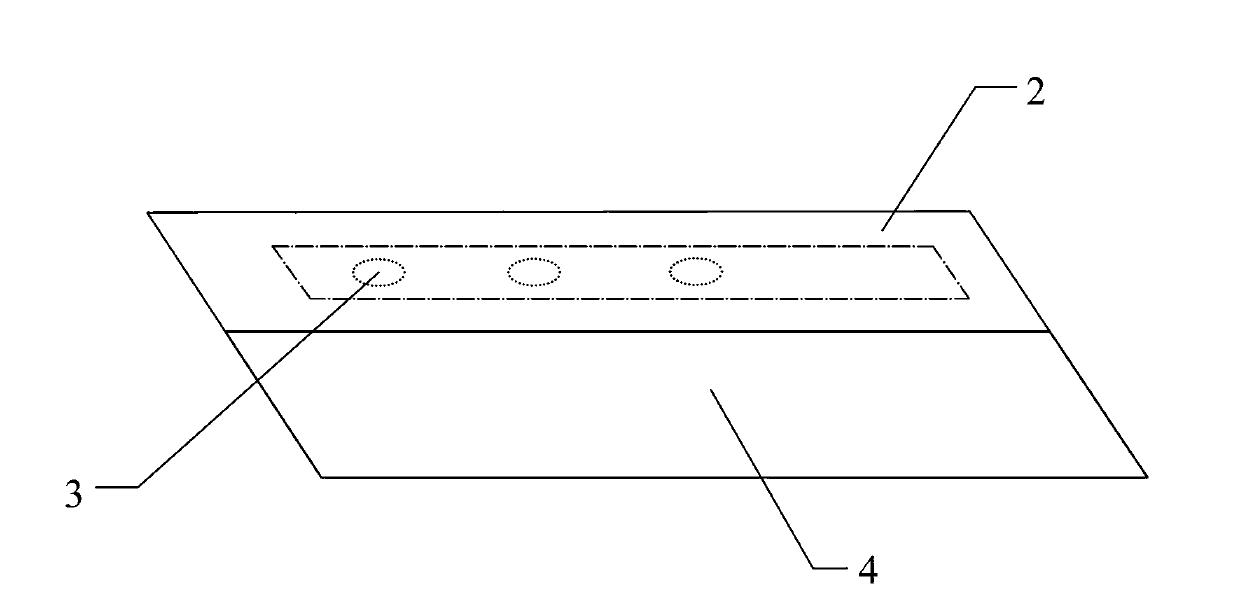

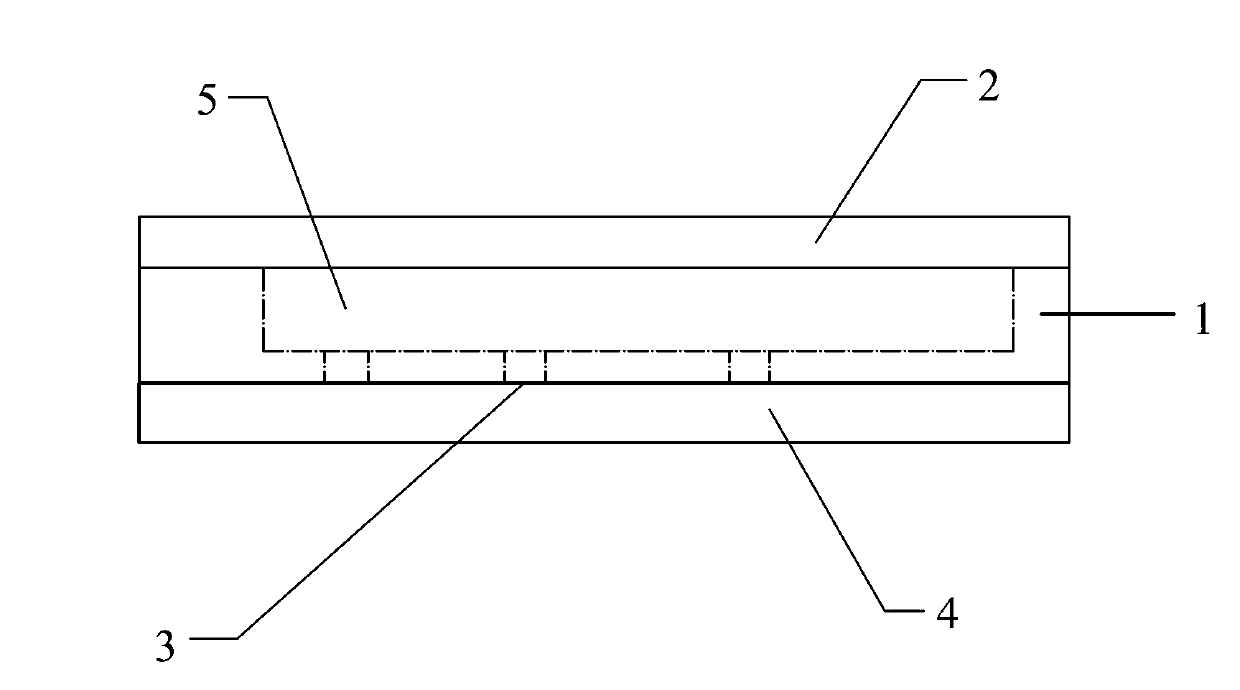

Stereo display electrode and manufacturing method thereof

A technology of three-dimensional display and display electrodes, which is applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problem of difficult control of photolithography process accuracy and production time, and the inability to effectively use flat panel display space, raw materials, environmental burden and energy. High energy consumption and other issues, to achieve the effect of improving visible light transmittance, increasing volume, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] On the glass substrate, an inorganic three-dimensional display electrode is made, the insulating layer material is made of domestic Ruihong RZJ304 positive photoresist, and the sealing insulating layer is made of SW-B UV-cured epoxy resin. Inorganic conductive materials use silver nanoparticle ink (SEINTRONICS INK), which has good dispersion and conductivity necessary for the formation of inkjet printed circuits, and can form high-quality auxiliary three-dimensional electrodes due to the characteristics of non-agglomeration and less clogging . The transparent thin film display electrode uses ITO thin film.

[0068] The specific process is as follows:

[0069] The glass substrate is coated, and the ITO film thickness of the transparent film display electrode is 100 angstroms;

[0070] Scrub with cleaning solution, the water temperature is 40 ° C, and the concentration of the clear solution is 10%;

[0071] Rinse and dry with ultrapure water at 40°C;

[0072] UV light...

Embodiment 2

[0090] On the PET substrate, a three-dimensional display electrode mixed with inorganic and organic is made, the insulating layer material is made of domestic Ruihong RZJ304 positive photoresist, and the sealing insulating layer is made of SW-B UV-cured epoxy resin. The organic conductive material uses PEDOT:PSS solution to form high-quality auxiliary three-dimensional electrodes. The transparent thin film display electrode uses ITO thin film.

[0091] The specific process is as follows:

[0092] Coating at low temperature on the PET substrate, the ITO film thickness of the transparent film display electrode is 100 angstroms;

[0093] Rinse with cleaning solution, the water temperature is 40 ° C, and the concentration of the clear liquid is 10%;

[0094] Rinse and dry with ultrapure water at 40°C;

[0095] Slight exposure to ultraviolet light to remove organic matter;

[0096] Spin-coating photoresist, the thickness is controlled at 0.5μm;

[0097] Exposure, 10mj / cm 2 ; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com