Sand-blasting protective clamp for centrifugal impeller combination

A technology for protecting fixtures and centrifugal impellers, applied in manufacturing tools, processing devices for used abrasives, abrasives, etc., to achieve the effects of improving production efficiency and product quality, saving production costs, and shortening the processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

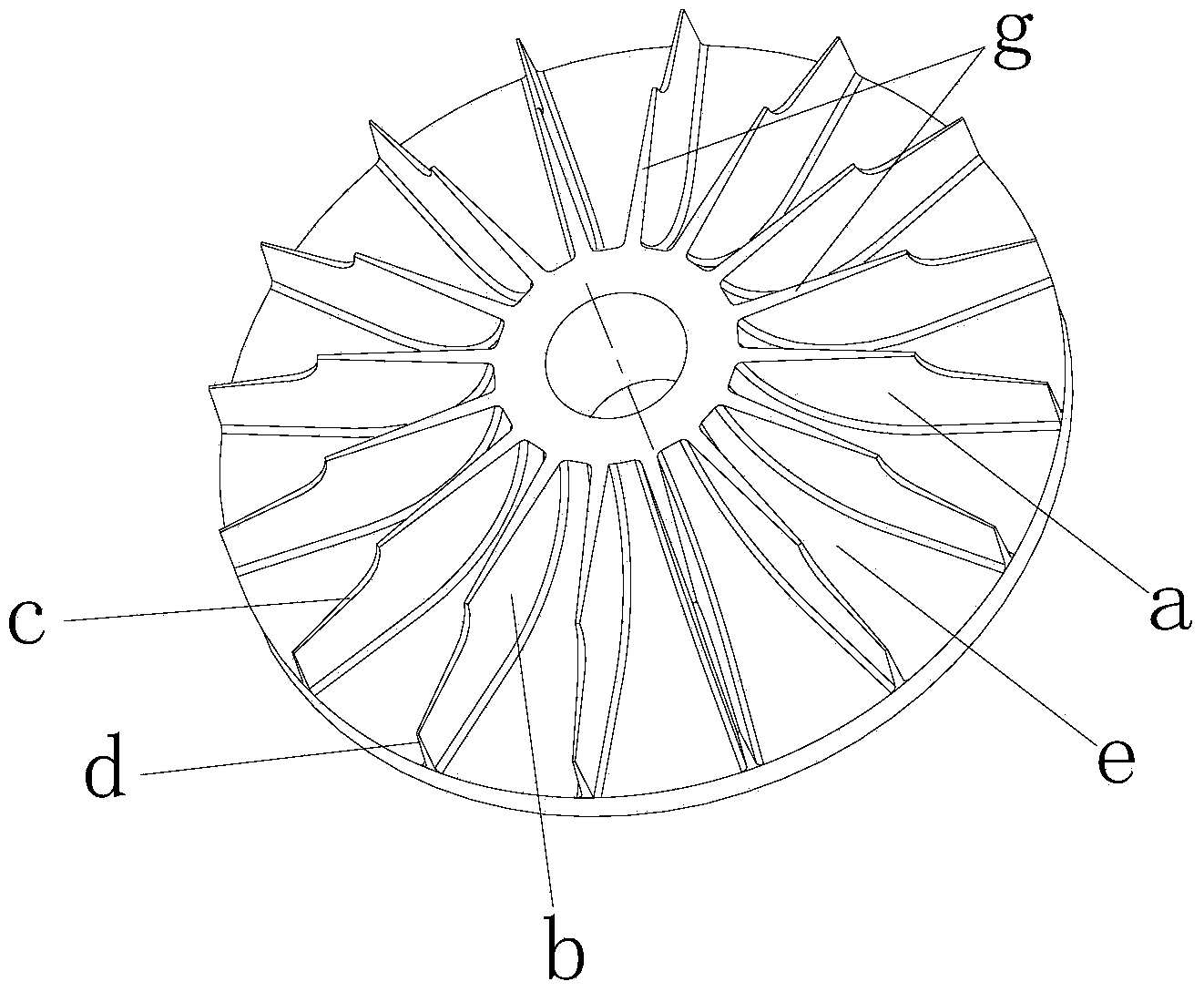

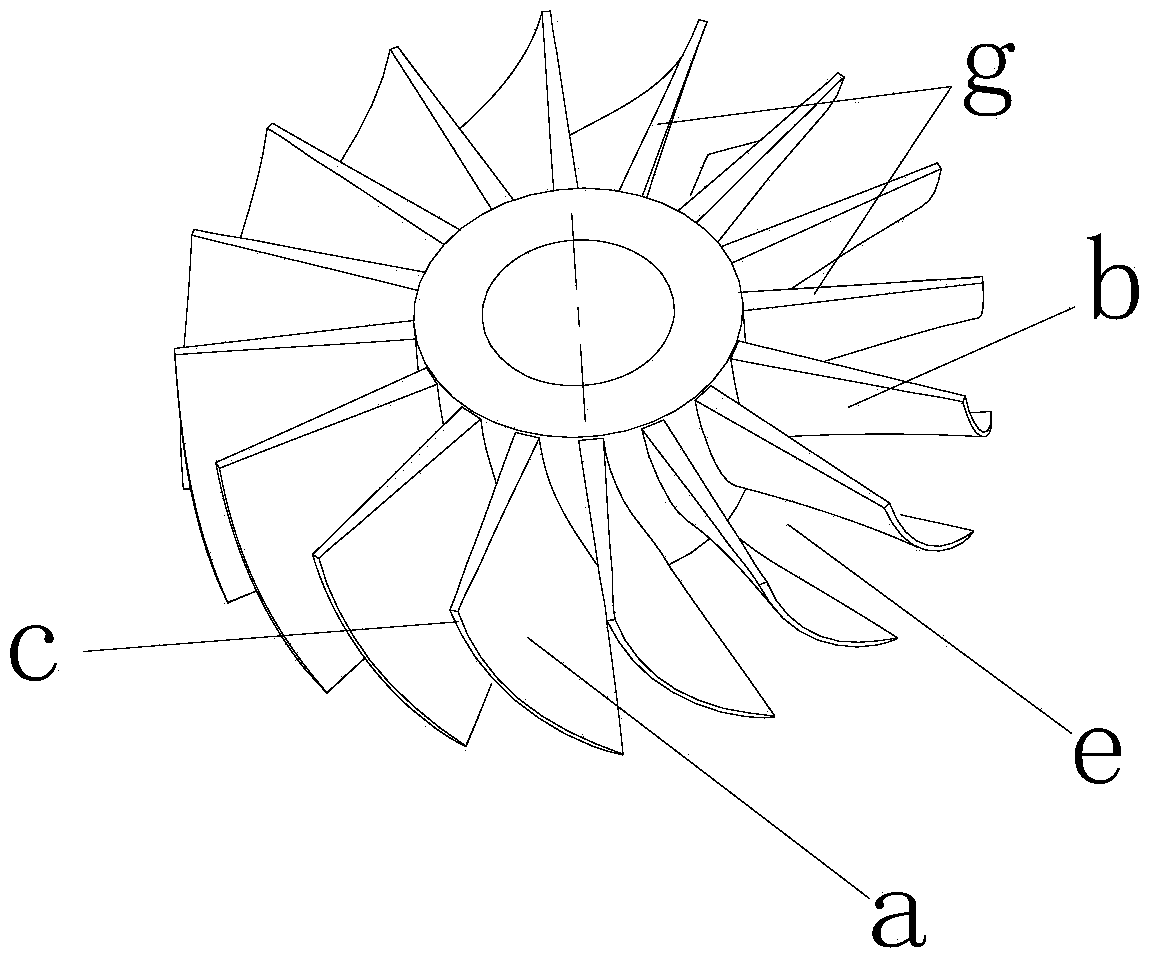

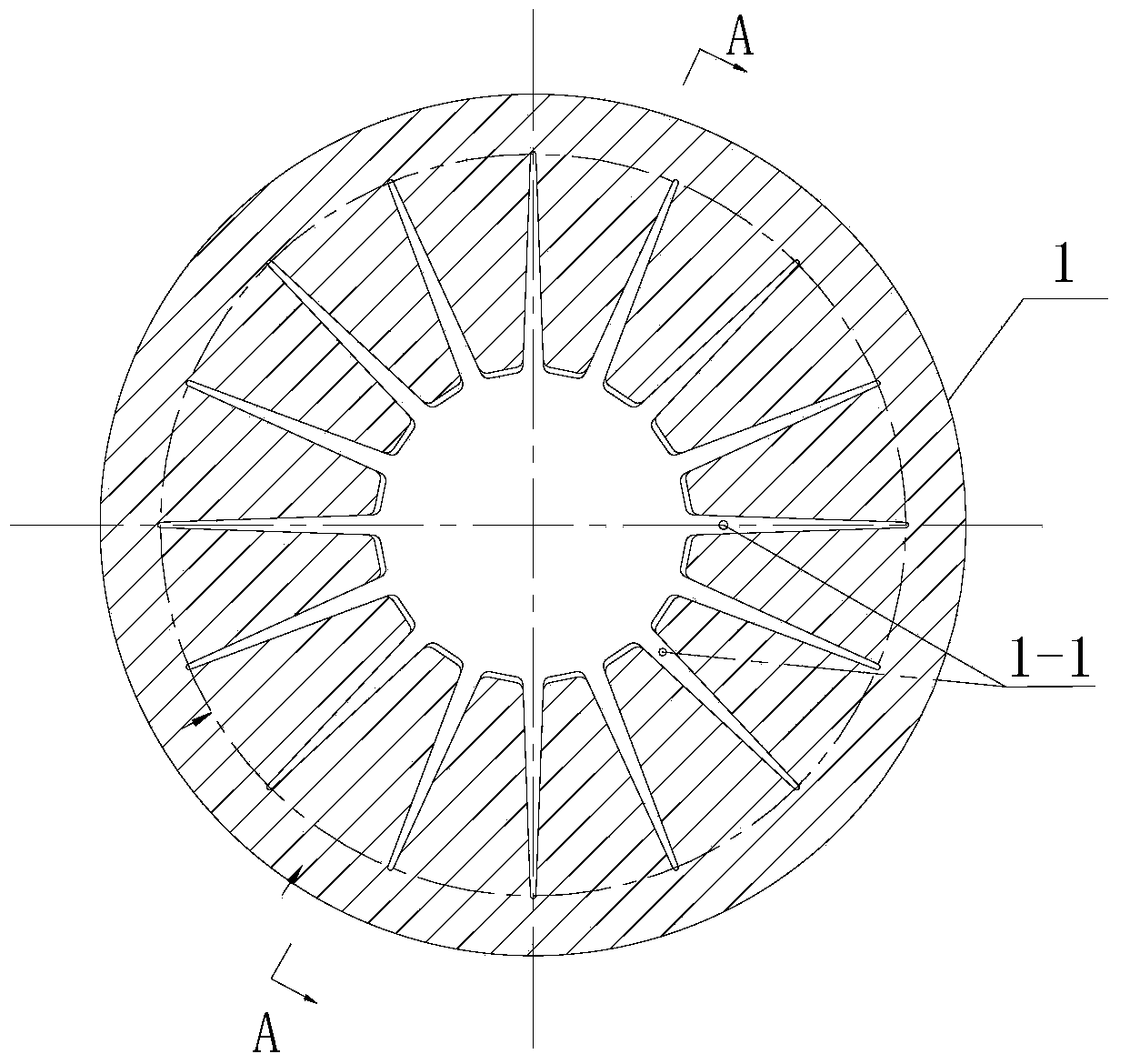

[0020] See figure 1 As shown in -4, a centrifugal impeller combined sand blowing protection fixture includes: first and second protection fixtures.

[0021] The first protective fixture includes: a first annular cover plate 1, a plurality of isosceles triangle notches 1-1 are distributed on the inner circle of the first annular cover plate 1, each notch 1-1 on the first annular cover plate 1 1 corresponds to the distribution of the surface to be sanded on each blade of the impeller, and the surface to be sanded on each blade of the impeller is suitable for being respectively embedded in each notch on the first annular cover plate 1- 1, and the assembly gap between each notch 1-1 on the first annular cover plate 1 and the surface to be sand-blown in the notch 1-1 is 0.3 to 0.6mm (preferably 0.5mm).

[0022] The second protective fixture includes: a second annular cover plate 1', a plurality of isosceles triangle notches 1-1 are distributed on the inner circle of the second ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com