Embedding mould suitable for anaerobic resins

An anaerobic resin and mold technology, which is applied in the field of anaerobic resin embedding molds, can solve problems such as difficult removal, poor sealing, and unsuitable shape and size, and achieve the effect of easy placement and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

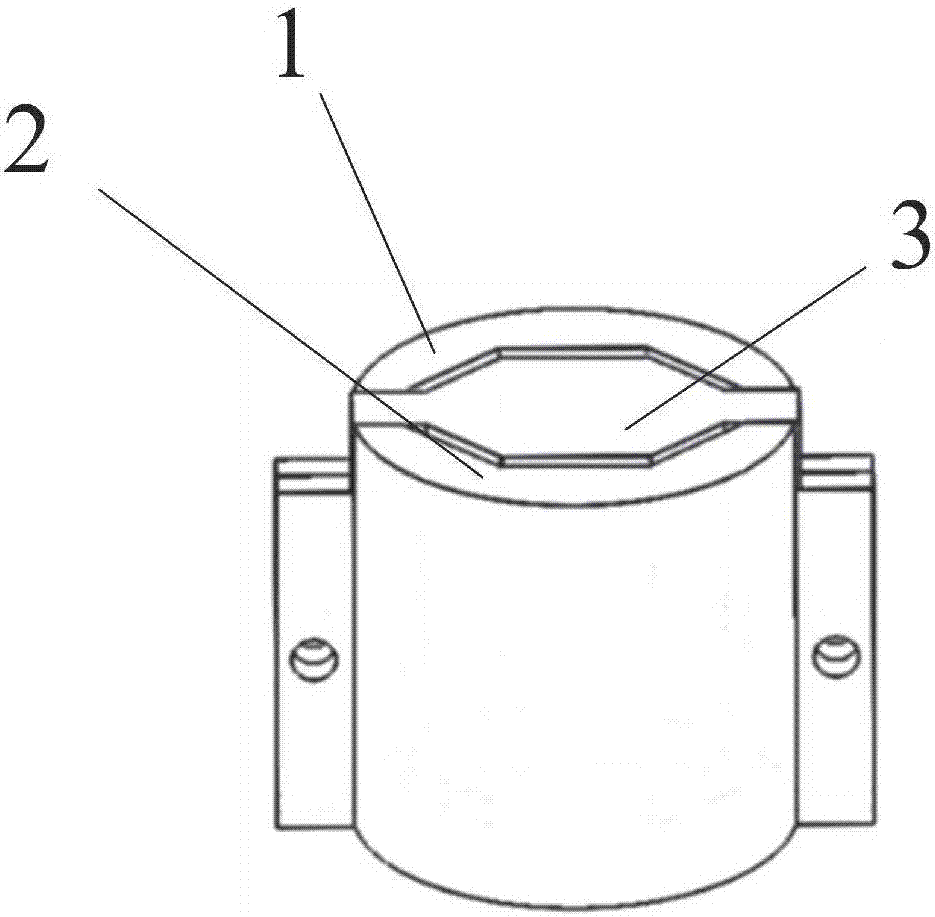

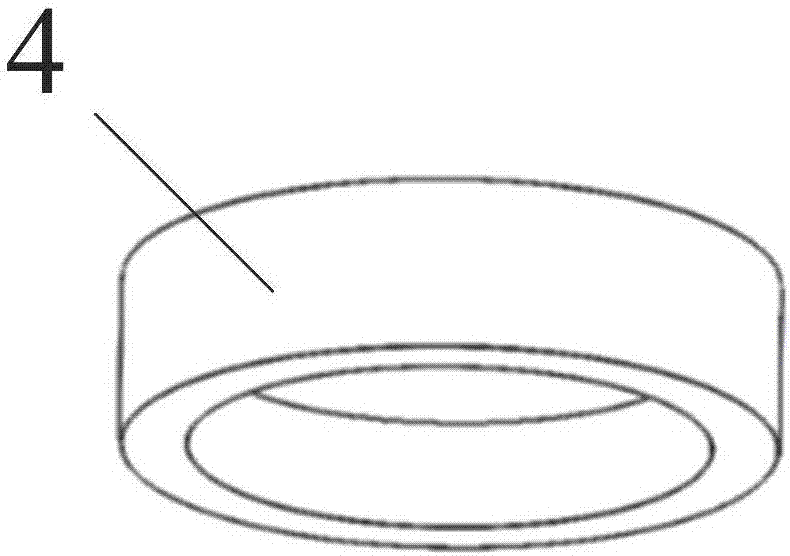

[0021] Such as figure 1 , figure 2 As shown, the present invention is applicable to the anaerobic resin embedding mold including left mold main body 1, right mold main body 2, solid octahedron 3, top cover 4, solid octahedron 3 both sides are respectively connected with left mold main body 1, right mold main body 2 Connection, the left mold main body 1, the right mold main body 2, and the solid octahedron 3 are all connected with the top cover 4, wherein:

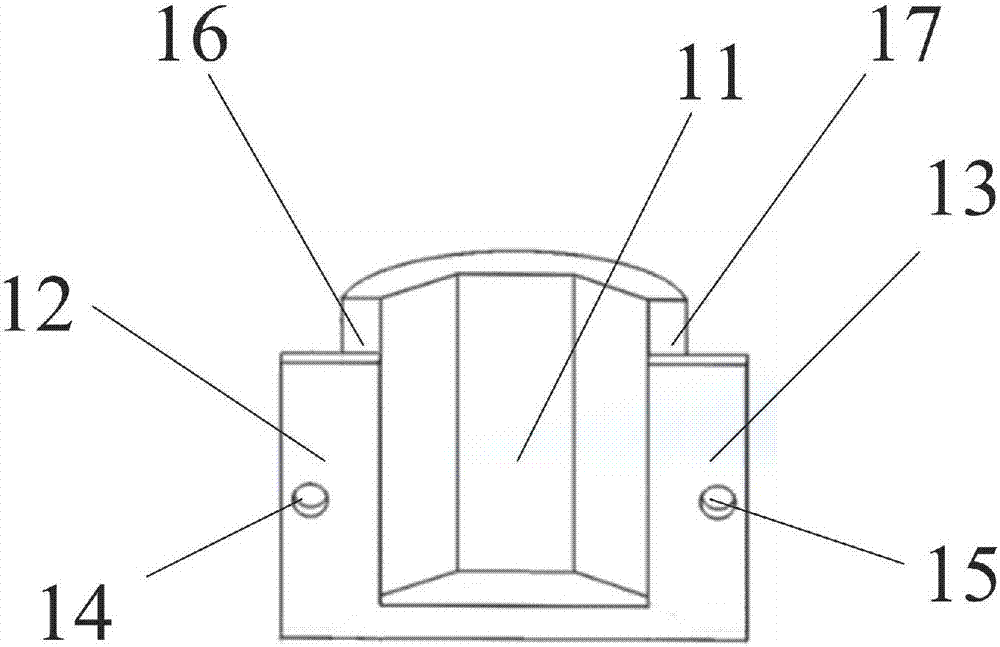

[0022] Such as image 3 As shown, the left mold body 1 includes an octagonal prism groove 11, a left convex strip 12, a right convex strip 13, a left threaded hole 14, a right threaded hole 15, a left notch 16, a right notch 17, a left convex strip 12, a right convex strip 13 are all connected with octagonal prism groove 11, and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com