Wood cutting device for active carbon processing

A cutting device, activated carbon technology, applied in wood processing appliances, manufacturing tools, special molding/shaping machines, etc., can solve the problems of waste of resources, time-consuming and laborious, and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

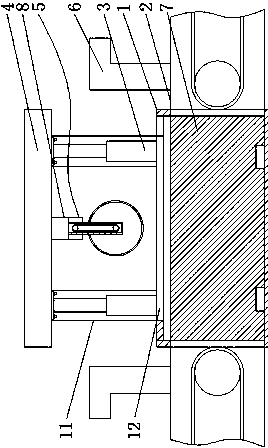

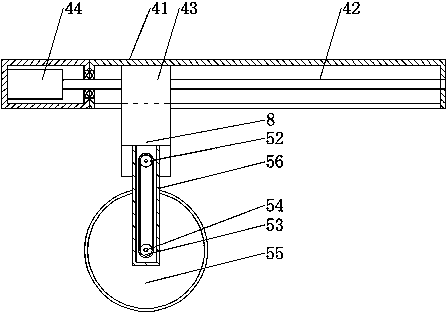

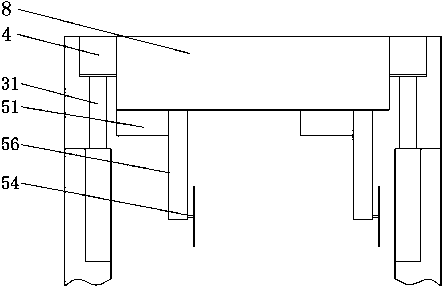

[0026] to combine Figure 1 to Figure 7 As shown, a wood cutting device for activated carbon processing disclosed in this embodiment includes: a collection box 1, a material delivery channel 2, a lifting device 3, a moving device 4 and a cutting device 5; the two ends of the collection box 1 are respectively A group of material delivery channels 2 are provided, and a material delivery conveyor belt 21 is arranged in the material delivery channel 2, and a preheating drying device 6 is also arranged in the material delivery channel 2, and one end of the material delivery channel 2 is provided with There is a feeding trough 22, the other end of the conveying channel 2 is communicated with the collecting box 1, the one end of the collecting box 1 is provided with a pressing device 7, and the two sides of the collecting box 1 are respectively provided with installation fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com