Adjustable high-precision biaxial slitting machine

A high-precision, adjustable technology, applied in metal processing, sending objects, thin material processing, etc., can solve the problems of difficult control of film width, unstable cutting quality, inconvenient replacement operation, etc., to achieve easy control of film size, Easy cutting quality, stable cutting quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

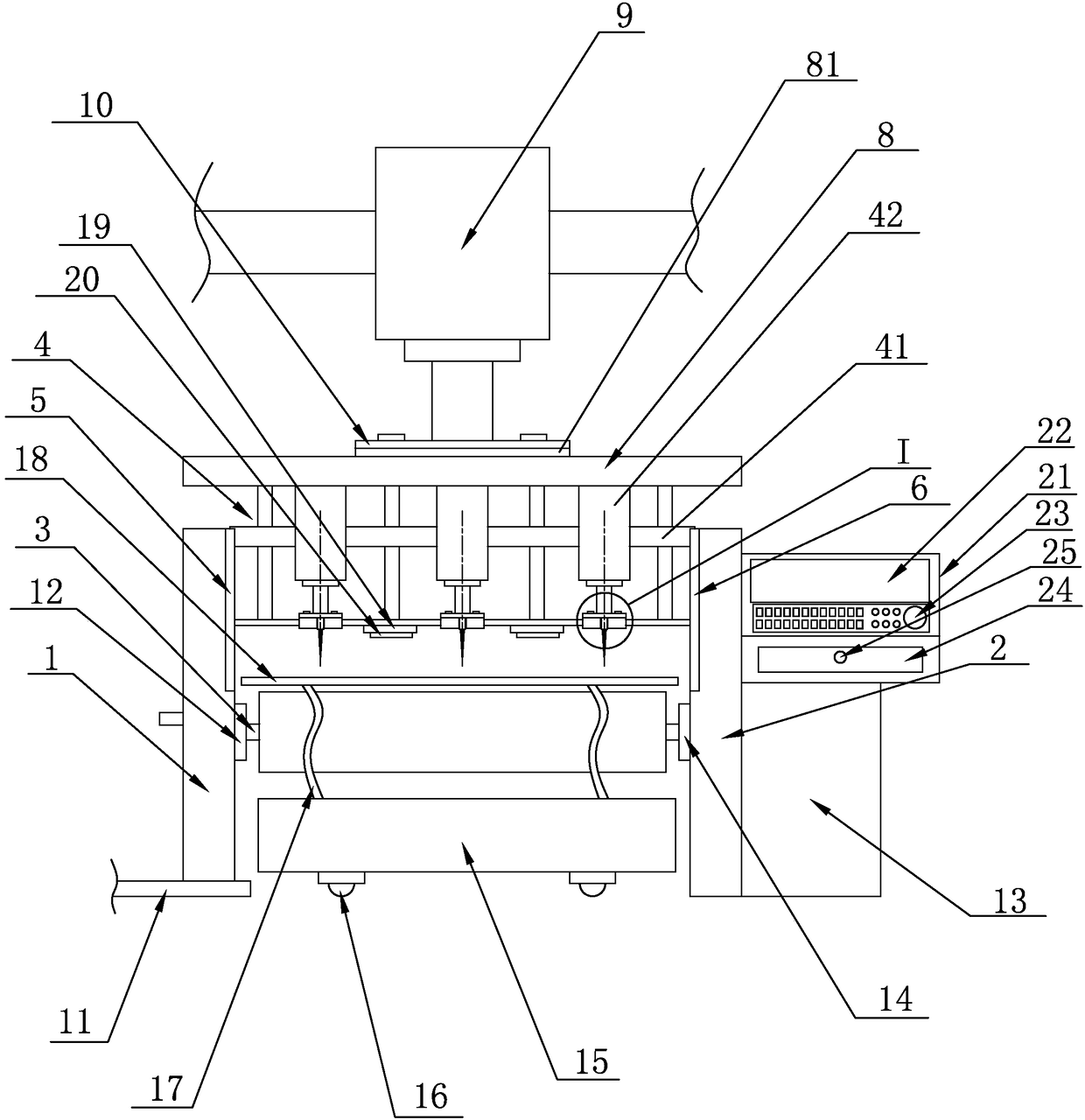

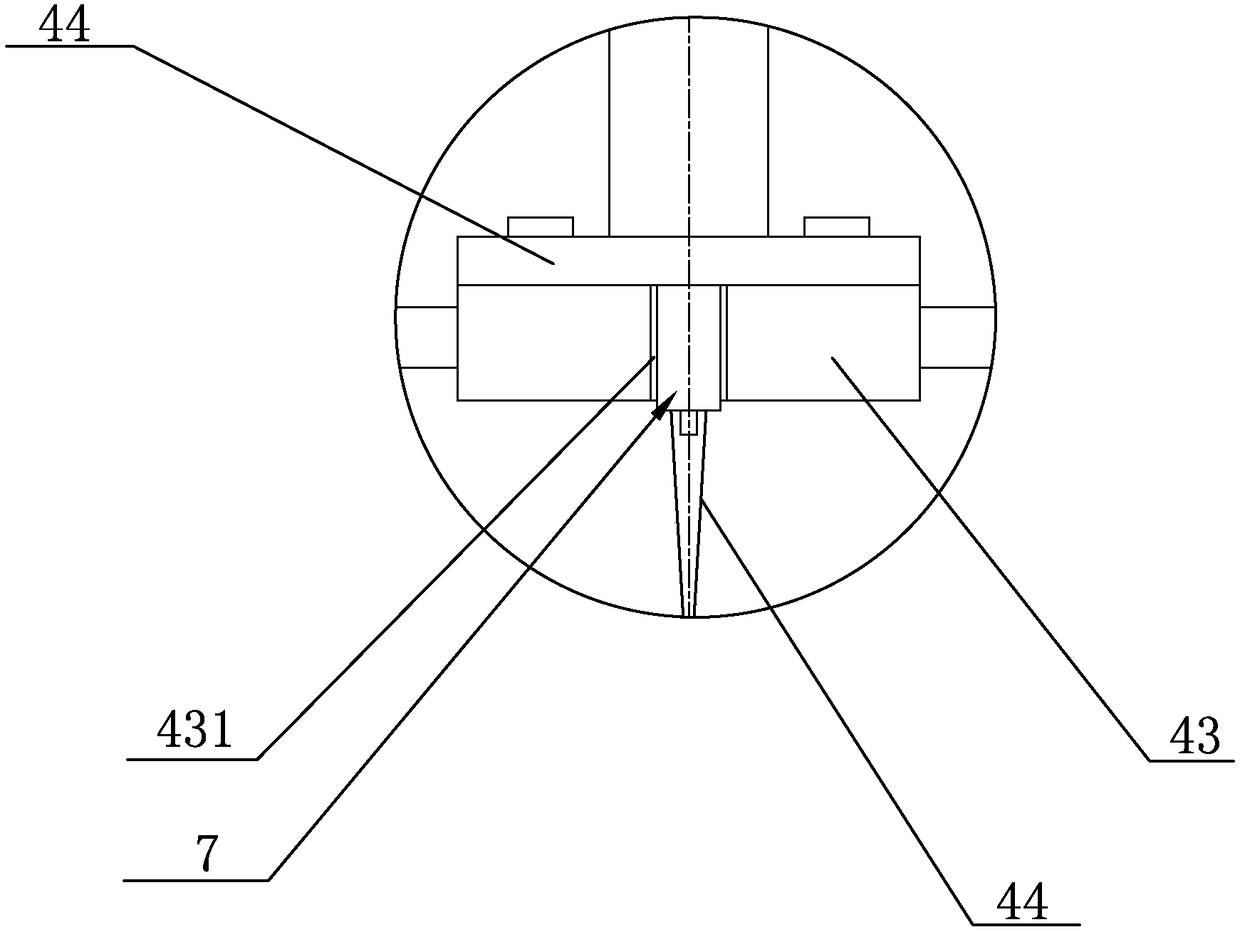

[0016] see figure 1 with figure 2 , an adjustable high-precision biaxial slitting machine disclosed by the present invention, comprising a left support 1, a right support 2 and a film roll 3, the film roll 3 is rotatably arranged on the left support 1 and the right support 2, the film A cutting tool device 4 is arranged above the roller 3, a left vertical guide rail 5 is welded on the right end surface of the left support 1, a right vertical guide rail 6 is welded on the left end surface of the right support 2, and the left vertical guide rail 5 and the right vertical guide rail 6 Symmetrically arranged; the cutting tool device 4 includes a cylinder frame 41, a cutter adjusting cylinder 42, a cutter fixing block 43 and a cutting knife 44, and several cutter adjusting cylinders 42 are detachably arranged on the cylinder frame 41, and each cutter adjusting cylinder 42 The piston rods are set downwards, and the lower end of the piston rod of each cutter adjustment cylinder 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com