Device for conveniently cutting radish to small strips

A convenient and radish technology, applied in metal processing, food processing, applications, etc., can solve the problems of waste, high resistance, radish breakage, etc., and achieve the effects of avoiding loss, stable cutting work, and convenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

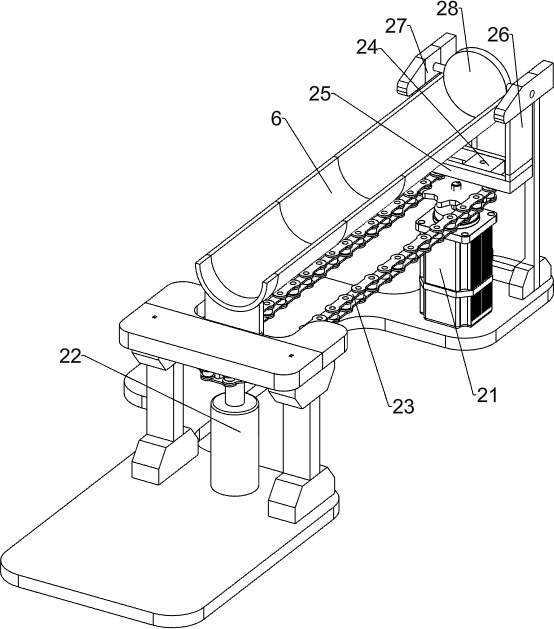

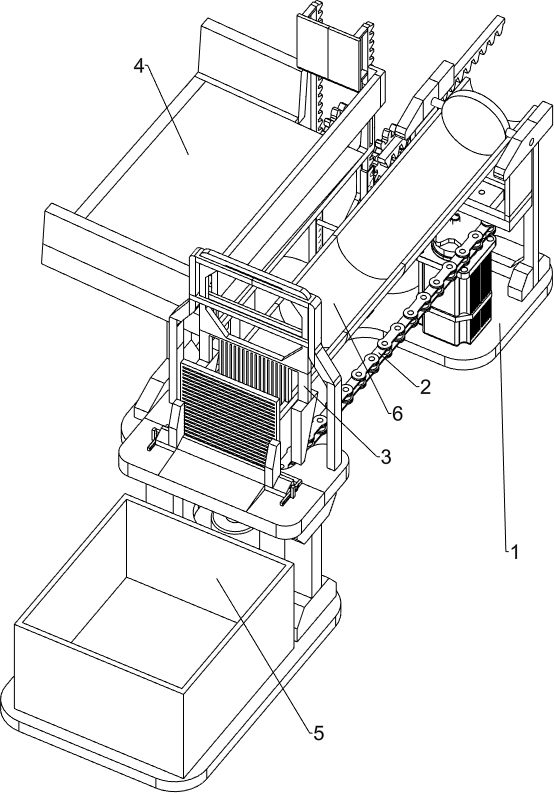

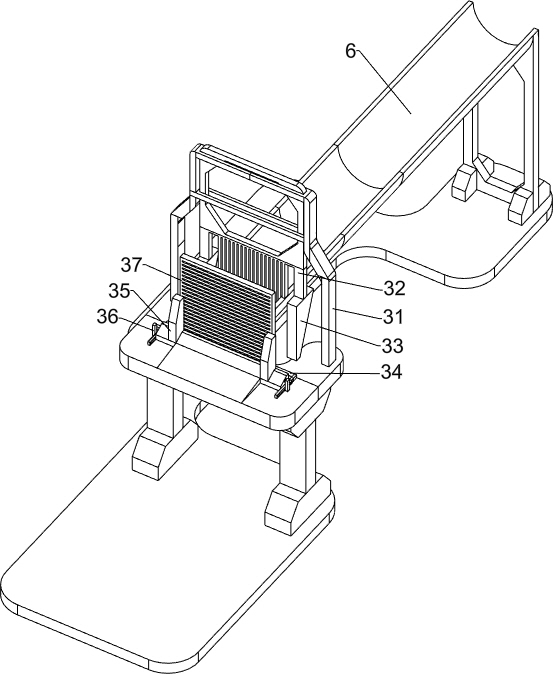

[0043] A kind of radish convenient cutting strip device, such as figure 1 As shown, it includes a mounting base 1, a power mechanism 2, a shred assembly 3 and a workbench 6. The shred assembly 3 is provided on the left side of the top of the mounting base 1, and the power mechanism 2 is connected between the left and right sides of the top of the mounting base 1. A workbench 6 is connected between the left and right sides of the seat 1 top.

[0044] When it is necessary to cut the radish into strips for making dried radish, the staff can put the radish into the working table 6, and then start the power mechanism 2 to work, and the power mechanism 2 works to transfer the radish to the shredding assembly 3 and cut it into pieces, and then The work of the power mechanism 2 drives the internal parts of the shredding assembly 3 to work, so that the internal parts of the shredding assembly 3 cut the block radishes into strips, and the staff can collect the cut radishes. After the ra...

Embodiment 2

[0046] On the basis of Example 1, such as figure 2 As shown, the power mechanism 2 includes a motor 21, a support column 22, a sprocket assembly 23, a slider 24, a slide rail 25, a connecting plate 26, a first wedge block 27 and a push plate 28, and the top right side of the mounting base 1 is provided with For the motor 21, a support column 22 is provided on the left side of the top of the mounting seat 1, and a sprocket assembly 23 is connected between the support column 22 and the output shaft of the motor 21, and a slide rail 25 is provided on the top of the sprocket assembly 23 near the motor 21 side. The slide rail 25 is slidingly connected with a slide block 24, the two ends of the slide block 24 are connected with a connecting plate 26, the top of the connecting plate 26 is provided with a first wedge block 27, and a push plate 28 is connected between the first wedge block 27, The push plate 28 is located in the workbench 6 .

[0047] Start the motor 21 to work, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com