Method for predrying, powdering and conveying feed coal and special processing system thereof

A pre-drying and raw material technology, which is applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of high nitrogen or carbon dioxide content, great influence on efficiency, weakening oxygen consumption and coal consumption reduction of dry pulverized coal gasification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1, raw coal pre-drying, pulverizing and conveying method and its special treatment system

[0074] 1. Special treatment system for raw coal pre-drying, pulverization and transportation

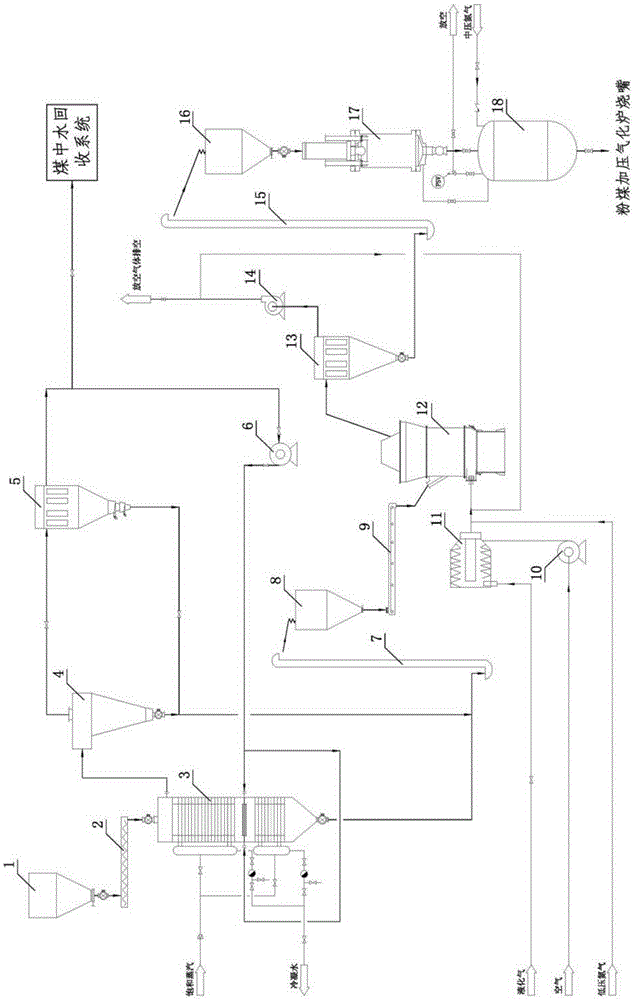

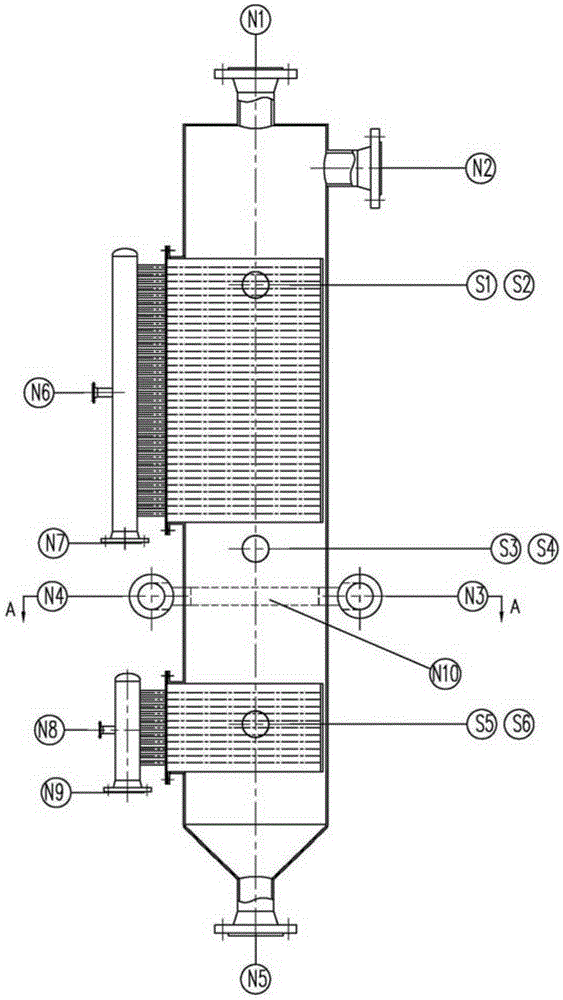

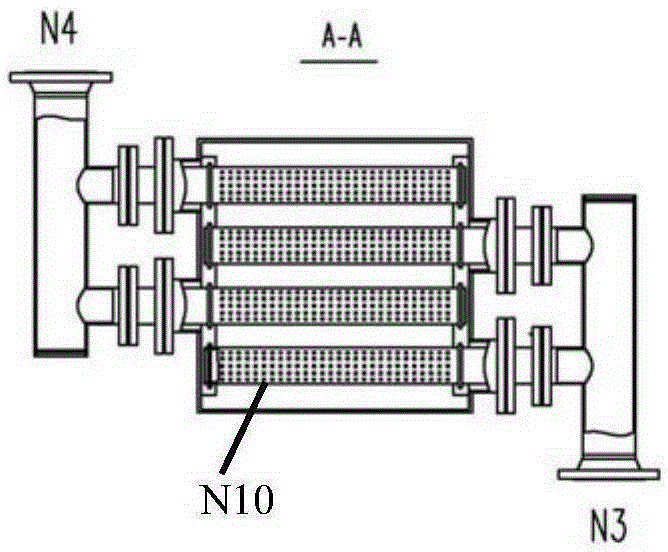

[0075] like figure 1 Shown is the special processing system of the method for raw coal pre-drying, pulverizing and conveying of the present invention, including pre-drying feed bin 1, fluidized bed drying furnace 3, pulverizing feed coal bunker 8, vertical Coal mill 12, pulverized coal bin 16, solid pulverized coal delivery pump 17 and high-pressure pulverized coal tank 18; the outlet of pre-drying feed bin 1 is connected with the feed port of fluidized bed drying furnace 3 through screw conveyor 2; The outlet of the fluidized bed drying furnace 3 is connected to the inlet of the pulverizing feed coal bunker 8 through the pre-drying bucket elevator 7, and the outlet of the pulverizing feed coal bunker 8 is connected to the vertical feeder 9 through the fully sealed belt feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com