Sludge breaking and centrifugal filtration integrated machine

A centrifugal filtration, all-in-one technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Gas pollution to the surrounding environment and other problems, to achieve the effect of small equipment footprint, low operating cost, and short cracking cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

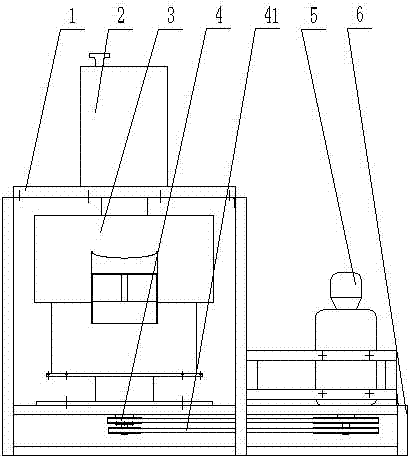

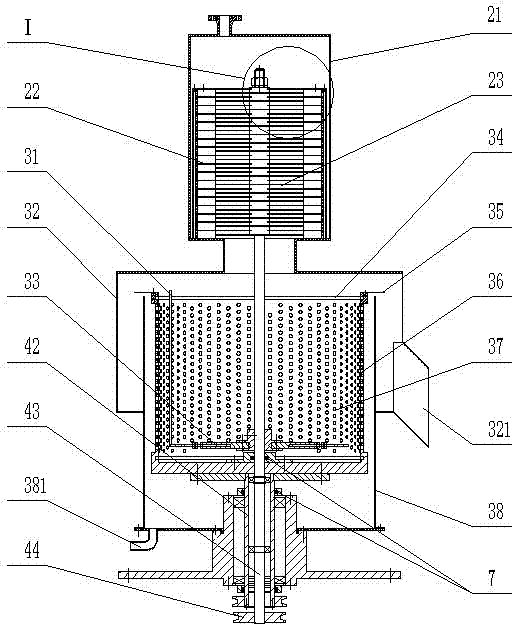

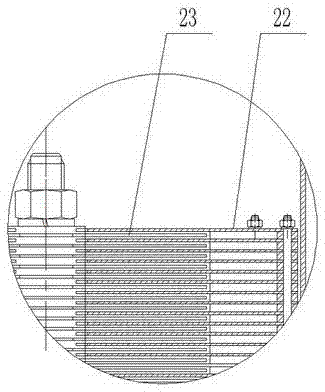

[0013] The present invention includes a machine base 6, a motor 5, a transmission device 4, a sludge cracking device 2, and a centrifugal filter device 3. The transmission device 4 includes a pulley 44, a belt 41, an inner shaft 43, an outer shaft 42, and the inner shaft 43 and the outer shaft 42 are concentric and connected to the motor 5 through the pulley 44 and the belt 41; the sludge cracking device 2 includes a cracking cavity 21 fixedly connected to the machine base 6 through the bracket 1, and a fixed disc 22 arranged on the inner wall of the cracking cavity 21 and the moving disc 23 arranged on the inner shaft 43, the fixed disc 22 and the moving disc 23 are arranged alternately in the axial direction; the centrifugal filter device 3 includes a filter cavity housing 32, a water collection tank 38 with a water outlet pipe 381 at the bottom, The elastic scraper 31, the annular baffle 35 and the filter hub 37 arranged on the outer shaft 42, the bottom of the filter cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com