Method for efficiently and synergically processing food waste and household kitchen waste based on single-phase wet anaerobic digestion

A technology for anaerobic digestion and catering waste, applied in the direction of microorganism-based methods, biochemical equipment and methods, biological sludge treatment, etc., can solve the problem of anaerobic reactor operation collapse, complex components of catering waste, and complicated process operations To achieve the effect of ensuring efficient and stable operation, improving degradation rate, and improving gas production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

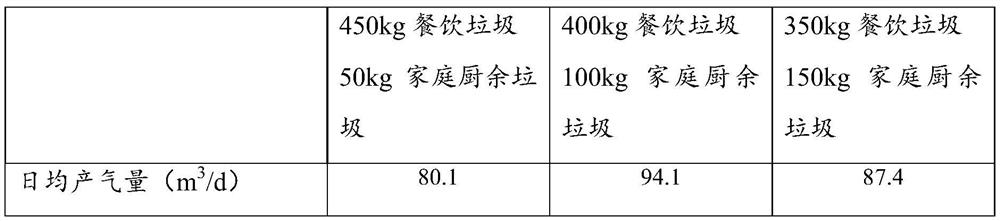

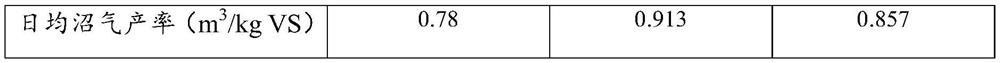

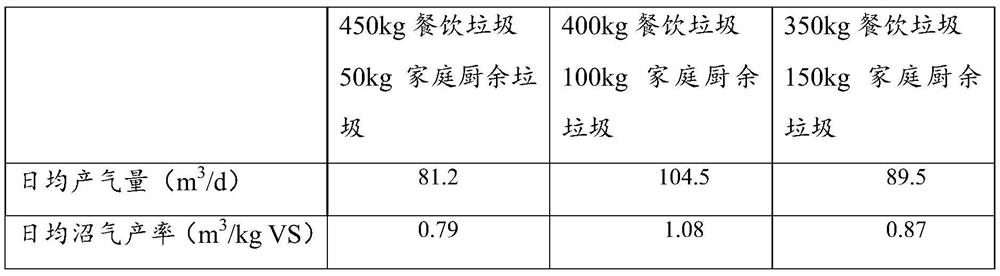

Embodiment 1

[0026] (1) Choose food waste in Chongqing area (organic degradable matter 92.3±5%, bone 2.8±1.5%, plastic 3.1±2%, pH6.7~7.0, solid content 22±2%, volatile solid 18±2% %) and household kitchen waste (kitchen waste 41.9±4%, paper product 25.8±2%, fruit peel 20.5±2%, plastic 11±1%, garden waste 8.7±1%, fiber fabric 6.2±1%, PH7 .1~8.0, solid content 18±2%, volatile solid 12±2%) as raw materials, pretreatment of food waste and household kitchen waste by removing impurities and pulping, removing large-sized glass and stones from raw materials Plastic bags, etc., made into a slurry with a particle size of less than 8mm.

[0027] (2) The design volume is 56m 3 , the actual effective volume is 50m 3 , the single-phase wet CSTR anaerobic digestion tank with a diameter-to-height ratio of 0.9 is used as the reactor, and the slurry of food waste and household kitchen waste is added to the anaerobic digestion reactor. The amount is 50kg / d.

[0028] Add 0.4L / day of trace element nutrient...

Embodiment 2

[0038] (1) Choose food waste in Chongqing area (organic degradable matter 92.3±5%, bone 2.8±1.5%, plastic 3.1±2%, pH6.7~7.0, solid content 22±2%, volatile solid 18±2% %) and household kitchen waste (kitchen waste 41.9±4%, paper product 25.8±2%, fruit peel 20.5±2%, plastic 11±1%, garden waste 8.7±1%, fiber fabric 6.2±1%, PH7 .1~8.0, solid content 18±2%, volatile solid 12±2%) as raw materials, pretreatment of food waste and household kitchen waste by removing impurities and pulping, removing large-sized glass and stones from raw materials Plastic bags, etc., made into a slurry with a particle size of less than 8mm.

[0039] (2) The design volume is 56m 3 , the actual effective volume is 50m 3 , the single-phase wet CSTR anaerobic digestion tank with a diameter-to-height ratio of 0.9 is used as the reactor, and the slurry of food waste and household kitchen waste is added to the anaerobic digestion reactor. The amount is 50kg / d. Add 0.5L / day of trace element nutrient solution...

Embodiment 3

[0048] (1) Choose food waste in Chongqing area (organic degradable matter 92.3±5%, bone 2.8±1.5%, plastic 3.1±2%, pH6.7~7.0, solid content 22±2%, volatile solid 18±2% %) and household kitchen waste (kitchen waste 41.9±4%, paper product 25.8±2%, fruit peel 20.5±2%, plastic 11±1%, garden waste 8.7±1%, fiber fabric 6.2±1%, PH7 .1~8.0, solid content 18±2%, volatile solid 12±2%) as raw materials, pretreatment of food waste and household kitchen waste by removing impurities and pulping, removing large-sized glass and stones from raw materials Plastic bags, etc., made into a slurry with a particle size of less than 8mm.

[0049] (2) The design volume is 56m 3 , the actual effective volume is 50m 3 , the single-phase wet CSTR anaerobic digestion tank with a diameter-to-height ratio of 0.9 is used as the reactor, and the slurry of food waste and household kitchen waste is added to the anaerobic digestion reactor. The amount is 50kg / d. Add 0.6L / day of trace element nutrient solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com