A kind of boiler anti-coking anti-corrosion treatment agent and preparation method and application thereof

A technology for corrosion treatment and boiler, which is applied in the field of anti-coking and anti-corrosion treatment agent for boiler and its preparation, which can solve the problems of coking and affect the thermal efficiency of the boiler, achieve uniform temperature, ensure safe and economical operation, and improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

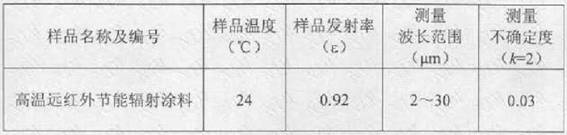

Image

Examples

Embodiment 1

[0035] An anti-coking and anti-corrosion treatment agent for boilers in this embodiment, the treatment agent includes, in parts by mass, 3 parts of zirconia, 5 parts of refractory fine soil, 5 parts of sodium soil powder, 13 parts of silicon carbide, and boron nitride. 13 parts, 20 parts of brown corundum, 1.5 parts of cobalt oxide, 10 parts of chromium oxide green, 10 parts of aluminum oxide, 12 parts of phosphoric acid solution, 6 parts of aluminum dihydrogen phosphate solution, 1 part of graphene, 2 parts of carboxymethyl cellulose, 17 parts water.

[0036] The fineness of the zirconia is 2500 meshes, the fineness of the refractory fine soil is 1000 meshes, the fineness of the sodium soil powder is 800 meshes, the fineness of the silicon carbide is 2500 meshes, the fineness of the boron nitride is 1500 meshes, The fineness of brown corundum is 3500 mesh, the fineness of cobalt oxide is 1200 mesh, the fineness of chrome oxide green is 3000 mesh, the fineness of alumina is 15...

Embodiment 2

[0049] An anti-coking and anti-corrosion treatment agent for boilers in this embodiment, the treatment agent includes, in parts by mass, 5 parts of zirconia, 10 parts of refractory fine soil, 5 parts of sodium soil powder, 13 parts of silicon carbide, and boron nitride. 15 parts, 25 parts of brown corundum, 2 parts of cobalt oxide, 10 parts of chromium oxide green, 10 parts of aluminum oxide, 10 parts of phosphoric acid solution, 5 parts of aluminum dihydrogen phosphate solution, 0.8-1 part of graphene, 1 part of carboxymethyl cellulose parts, 15 parts of water.

[0050] The fineness of the zirconia is 3000 meshes, the fineness of the refractory fine soil is 1000 meshes, the fineness of the sodium soil powder is 1000 meshes, the fineness of the silicon carbide is 3000 meshes, the fineness of the boron nitride is 1500 meshes, The fineness of brown corundum is 3500 mesh, the fineness of cobalt oxide is 1500 mesh, the fineness of chromium oxide green is 3000 mesh, the fineness of...

Embodiment 3

[0057] An anti-coking and anti-corrosion treatment agent for boilers in this embodiment, the treatment agent includes, in parts by mass, 4 parts of zirconia, 8 parts of refractory fine soil, 4 parts of sodium soil powder, 12 parts of silicon carbide, and boron nitride. 14 parts, 23 parts of brown corundum, 1.5 parts of cobalt oxide, 13 parts of chromium oxide green, 11 parts of aluminum oxide, 11 parts of phosphoric acid solution, 5.5 parts of aluminum dihydrogen phosphate solution, 0.9 parts of graphene, 1.5 parts of carboxymethyl cellulose, 16 parts water.

[0058] The fineness of the zirconia is 2500 meshes, the fineness of the refractory fine soil is 800 meshes, the fineness of the sodium soil powder is 800 meshes, the fineness of the silicon carbide is 2500 meshes, the fineness of the boron nitride is 1500 meshes, The fineness of brown corundum is 3500 mesh, the fineness of cobalt oxide is 1200 mesh, the fineness of chrome oxide green is 3000 mesh, the fineness of alumina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com