Removal device and removal method for wastewater containing bisphenol A

A wastewater and aeration device technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve high energy consumption, secondary pollution, poor adaptability to initial concentration fluctuations of chemical and electrochemical oxidation methods, etc. problems, achieve the effect of solving clogging and oxygen-enrichment problems, improving impact resistance, and compensating for instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

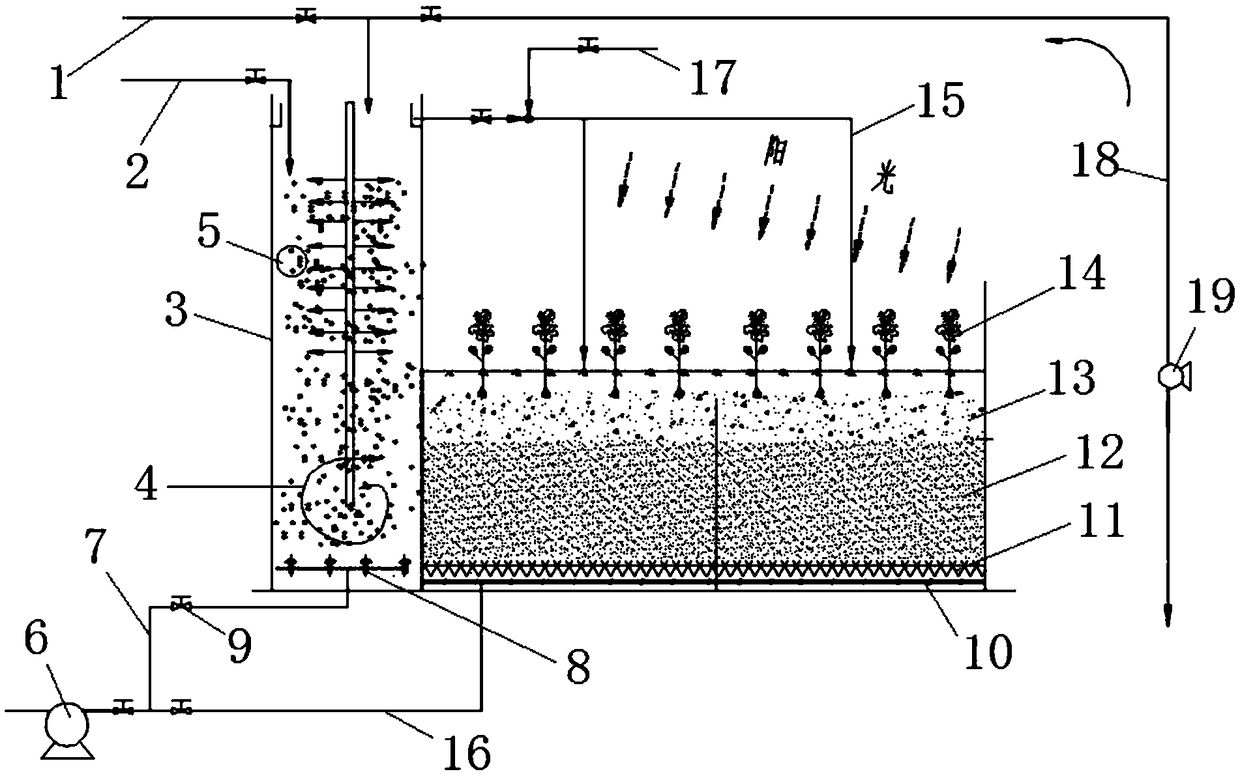

Method used

Image

Examples

Embodiment 1

[0050] S1, configure BPA simulated wastewater 12mg / l, collect domestic sewage COD Cr 351mg / L, BOD 5 167mg / L, ammonia nitrogen 26mg / L, total phosphorus 2.2mg / L;

[0051] S2. Adjust the flow rate of BPA simulated wastewater to 5L / h, adjust the initial pH of simulated BPA wastewater to 4.5, and add 1.2g / L of α-Fe 2 o 3 The amount of photocatalyst, the amount of peroxysulfate added is 0.4g / L, the aeration rate is controlled to be 0.6L / min, and the concentration of BPA in the effluent is 1.05mg / L by high-performance liquid chromatography and the national standard method;

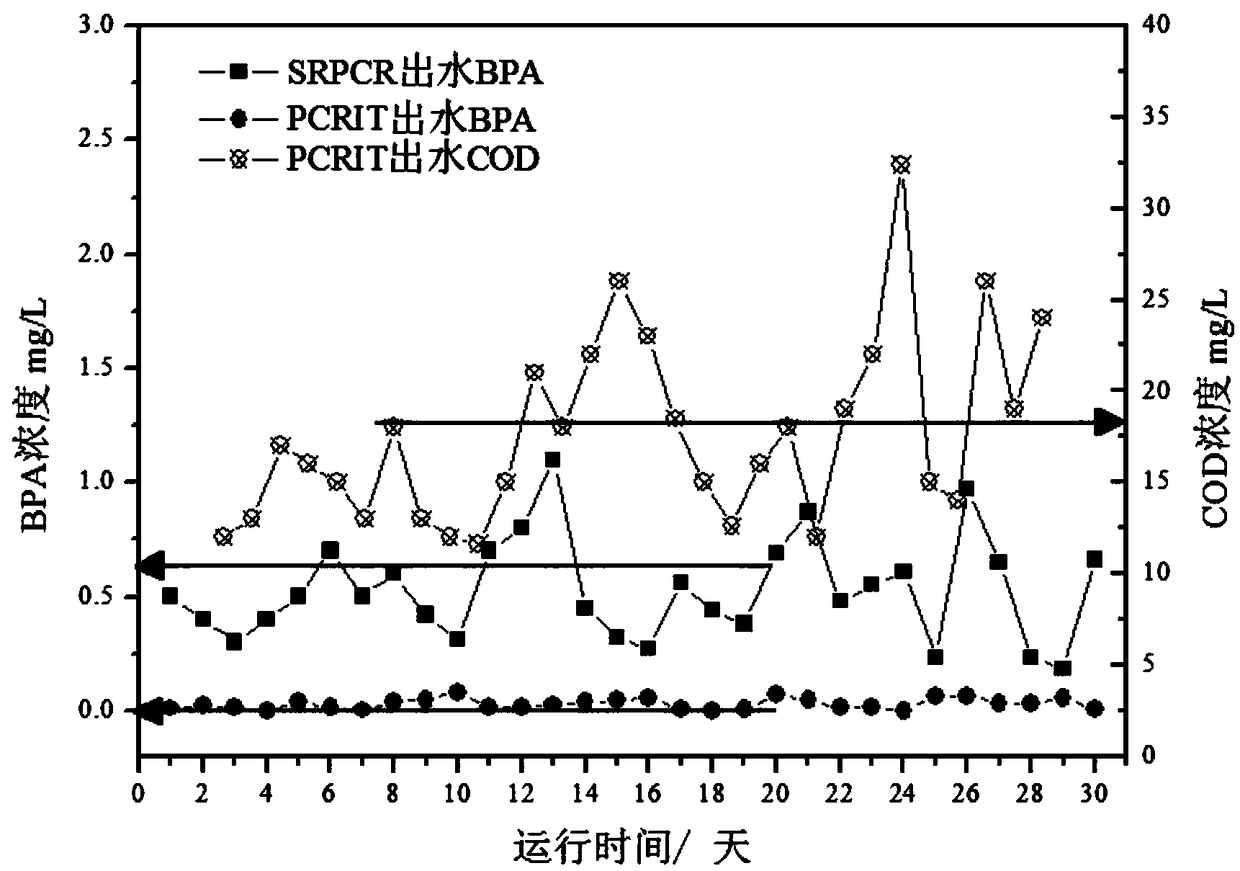

[0052] S3. SRPCR treats the effluent, adjusts the domestic sewage flow rate to 5L / h, and merges it into PCRIT. The operating cycle is 24 hours, and the single pool working cycle is 12 hours. The wet-dry ratio is controlled to be 1:1, that is, 1 hour is used for water distribution and 3 hours for Drainage, 4h is used for drying, using high-performance liquid chromatography and national standard method detection...

Embodiment 2

[0054] S1, configure BPA simulated wastewater 2mg / l; collect domestic sewage COD Cr 269mg / L, BOD 5 105mg / L, ammonia nitrogen 11mg / L, total phosphorus 1.8mg / L;

[0055] S2. Adjust the flow rate of BPA simulated wastewater to 5L / h, adjust the initial pH of simulated BPA wastewater to 5, and add 1.0g / L of α-Fe 2 o 3 The amount of photocatalyst is 0.6g / L peroxosulfate, the aeration rate is controlled at 0.5L / min, and the concentration of BPA in the effluent is 1.2mg / L when detected by high-performance liquid chromatography and the national standard method;

[0056] S3. SRPCR treats the effluent, adjusts the domestic sewage flow rate to 5L / h, and merges it into PCRIT. The operation cycle is 24 hours, and the single pool work cycle is 12 hours. The wet-dry ratio is controlled to be 1:1, that is, 1 hour is used for water distribution and 5 hours is used for Drainage, 6h for drying, using high-performance liquid chromatography and national standard method detection, PCRIT effluent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com