Coal gangue blending combustion anti-coking treatment method

A treatment method, coal gangue technology, applied in the petroleum industry, solid fuel, fuel additives, etc., can solve the problems of 1% to 2.5% reduction in thermal efficiency, increased ventilation resistance, destructive consequences, etc., to reduce boiler operating costs, Suppresses coking in boilers, and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

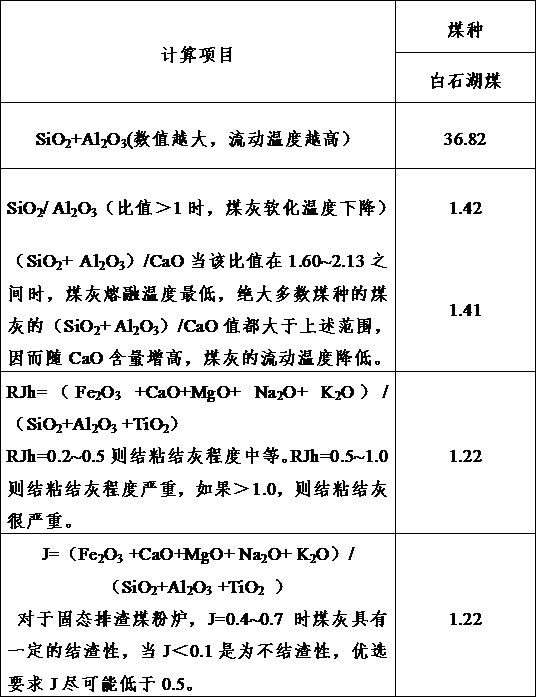

[0023] Implementation method: Based on the coal quality of Guanghui Baishi Lake, conduct blending tests of other coal types and media, adjust the combustion, adjust the blending ratio, observe in the furnace, collect data, analyze and compare, and finally obtain the best blending plan.

[0024] Through the comprehensive elemental analysis, industrial analysis, and characteristic analysis and comparison of Baishi Lake coal, it is concluded that Guanghui Baishi Lake coal in Yiwu County, Hami, Xinjiang belongs to high coking and high pollution coal, and its coal characteristics are very close to Xinjiang Zhundong coal characteristics. The specific analysis and comparison materials are shown in Table 1.

[0025] Table 1

[0026] project unit Baishi Lake Coal Coal ash melting characteristic temperature / deformation temperature (DT) ℃ 1240 Coal ash melting characteristic temperature / softening temperature (ST) ℃ 1270 Coal Ash Fusion Characteristic Temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com