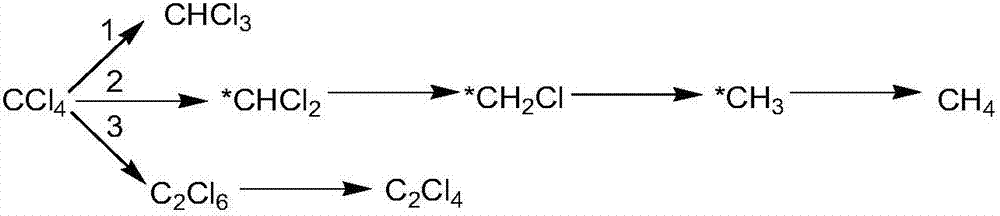

High-efficiency catalyst for producing chloroform by gas phase hydrogenation of carbon tetrachloride

A technology for dechlorination to chloroform and carbon tetrachloride, which is applied in the field of high-efficiency catalysts, can solve problems such as harsh reaction conditions, reduced catalyst activity, and difficult regeneration, achieve high conversion rate and selectivity, prolong catalyst life, alleviate coking and The effect of carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific implementation examples

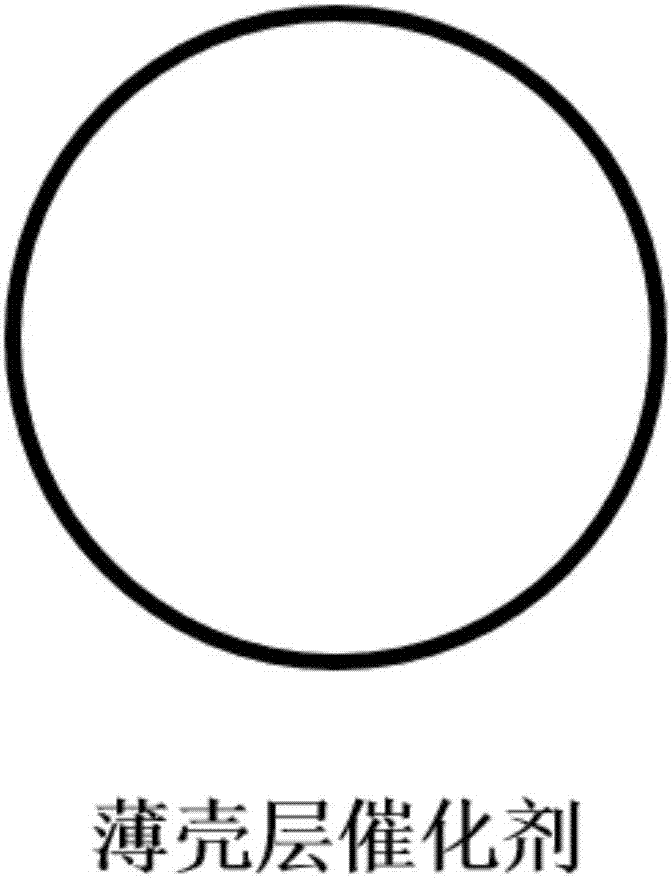

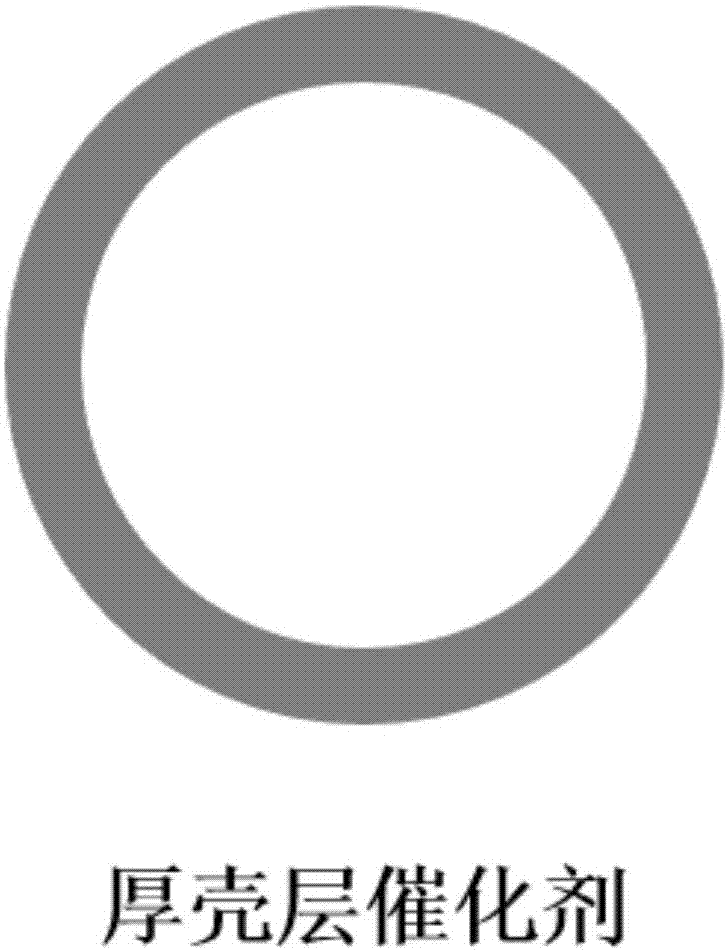

[0026] 1. Preparation of thin shell catalyst

[0027] Material preparation:

[0028] 100g round and straight active γ-Al2O3 carrier, particle size 2.5mm, particle length 5-15mm, compressive strength ≥ 38N / cm, bulk density 0.4±0.05g / ml, leaching aqueous solution is weakly acidic, put it into a beaker; 1.867g of chloroplatinic acid hydrate with a Pt content of about 37.5%, equivalent to 0.700g of Pt, was dissolved in 150g of deionized water.

[0029] Preparation:

[0030] Quickly pour the chloroplatinic acid aqueous solution on the carrier, and rotate and mix evenly, so that the chloroplatinic acid is evenly distributed on the carrier, then stand for 1 hour, and rotate from time to time, filter, bake at 120°C for 2h, and then bake at 250°C for 2h, put Put it into a tubular reactor, replace the air with nitrogen, switch to a small flow of hydrogen, reduce at 350 ° C for 4 hours, continue to flow hydrogen and cool to room temperature na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com