Method and apparatus for continuously and rapidly separating pyrolysis oil

A pyrolysis oil, fast technology, applied in the energy field to increase the degree of turbulence, simple and convenient operation, and avoid static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

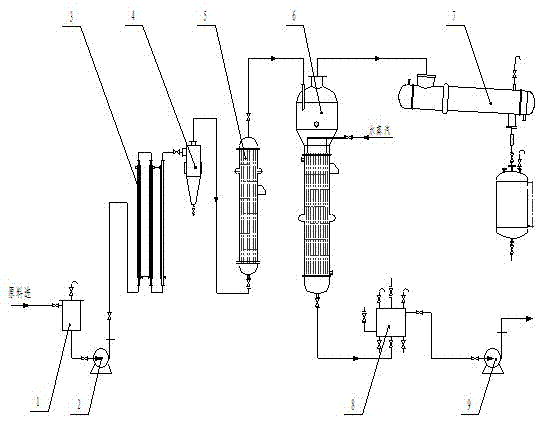

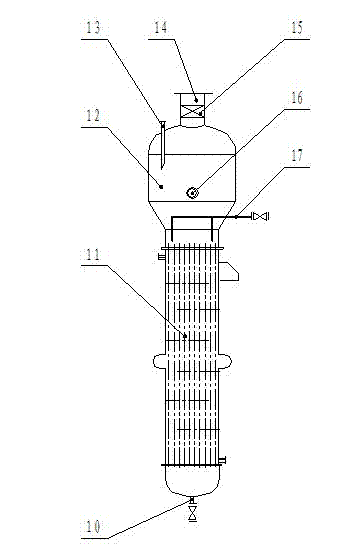

[0036] Example 1: Send waste plastic oil into a filter to remove particulate impurities below 100 mesh. Control the flow rate of the material at about 2m / s, and send it into the standpipe preheater by the feed pump and heat it to 80°C. Then the material enters the hydrocyclone to separate the remaining impurities in the material. Then it enters the evaporation preheater to preheat the material to 160°C, and finally enters the evaporator. The temperature of the evaporator is maintained at 190°C and steam is fed all the time, and about 50kg of steam at 160°C is fed into every 1000kg of plastic oil. Due to the existence of steam, the boiling point of the high boiling point components in the plastic oil is reduced, and the steam carries the distilled components into the condenser for condensation recovery. The unevaporated heavy components enter the discharge pump from the bottom of the evaporator and are sent to the finished product storage tank.

[0037] Table 1 is the proper...

Embodiment 2

[0039] Embodiment 2: waste rubber oil is sent into filter, removes particle impurity below 100 orders. Control the flow rate of the material at 3m / s, send it into the standpipe preheater by the feed pump and heat it to 100°C. Then the material enters the hydrocyclone to separate the remaining impurities in the material. Then it enters the evaporation preheater to preheat the material to 170°C, and finally enters the evaporator. The temperature of the evaporator is maintained at 190°C and steam is fed all the time, and about 80kg of steam at 180°C is fed into every 1000kg of plastic oil. Due to the existence of steam, the boiling point of the high boiling point components in the plastic oil is reduced, and the steam carries the distilled components into the condenser for condensation recovery. The unevaporated heavy components enter the discharge pump from the bottom of the evaporator and are sent to the finished product storage tank.

[0040] Table 2 is the property change ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com