Condense-dilute type double-cyclone cylinder pulverized coal burner and pulverized coal boiler using same

A technology of pulverized coal burners and pulverized coal boilers, which is applied in the direction of burning powder fuel burners, burners, and the combustion of lump fuel and powder fuel, to achieve the effects of small changes, reduced NOx emissions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

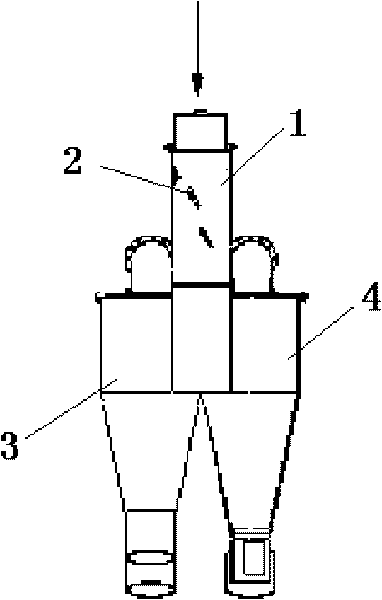

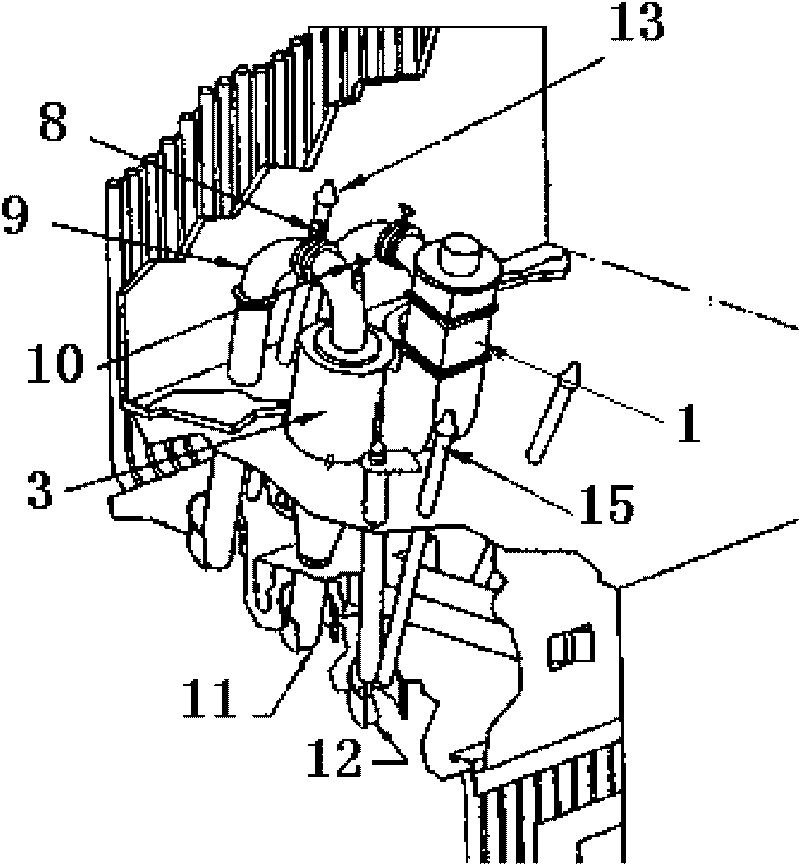

[0019] Specific embodiments of the present invention, such as figure 1 As shown, a thick-lean double-cyclone pulverized coal burner includes a pulverized coal inlet channel 1 and two cyclone-separated burners connected to the pulverized-coal inlet channel 1, and the pulverized coal nozzle of the cyclone-separated burner is located at the bottom of the boiler In the furnace, one of the two cyclone-separated burners, one cyclone-separated burner 3, is adjacent to the side wall and wing wall of the boiler, and the other cyclone-separated burner 4 is far away from the side wall and wing wall of the boiler. 1 is equipped with a pulverized coal concentrator 2, and the blades of the pulverized coal concentrator are inclined toward the side away from the side wall and wing wall of the adjacent boiler along the direction of the pulverized coal flow, so that the coal pulverized Distributed against the wall.

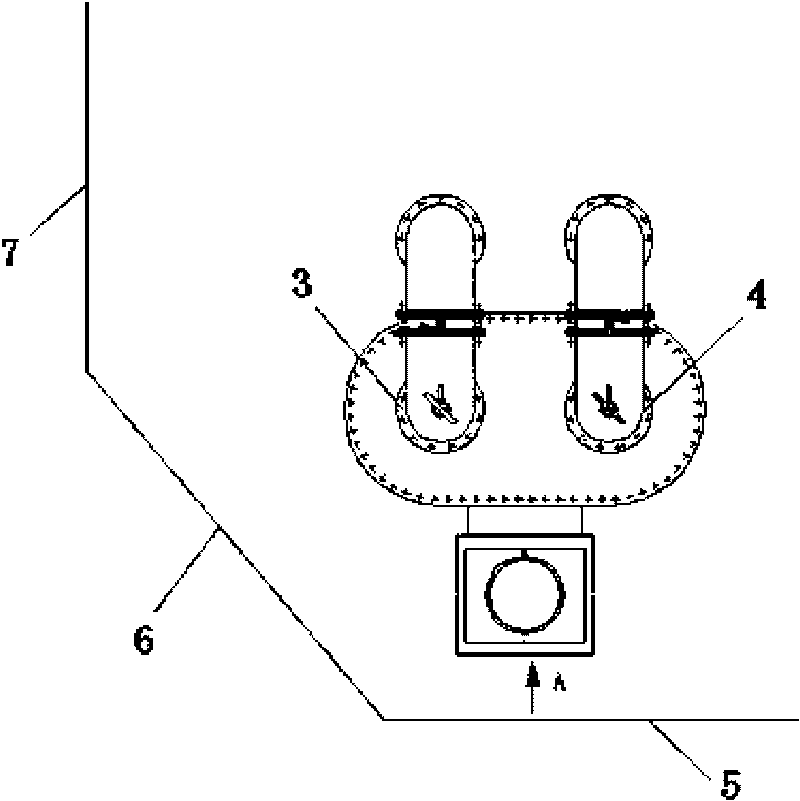

[0020] Such as figure 2 Shown, be that a above-mentioned thick-thin type d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com