Process for preparing trimethylolpropane by adopting centrifugal filtering calcium method

A technology of trimethylolpropane and preparation process is applied in the new process field of plate filter press method, which can solve the problems of environmental hazards of sewage, waste of manpower and material resources, etc., and achieve the effects of reducing extraction, reducing floor space and reducing sedimentation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

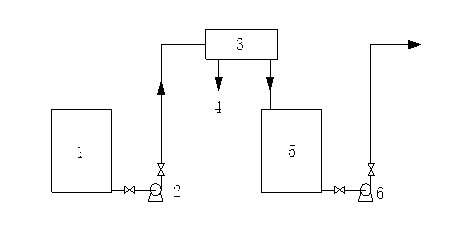

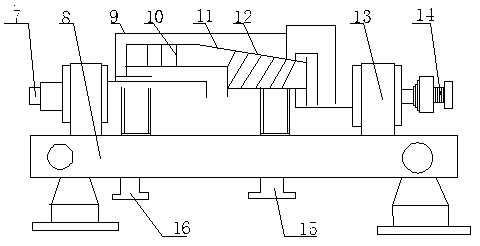

[0028] (1) Feed according to 10mol n-butyraldehyde, feed formaldehyde, n-butyraldehyde, and calcium hydroxide according to 3.2:1:0.8, the mass content of calcium hydroxide is 90%, obtain the reaction liquid for separation, start the screw centrifuge to The speed is 3000 rev / min. Centrifuged out is a clear mother liquor, the removal rate of impurities is 98%, the specific operation is as follows: figure 1 The reaction solution in the reaction solution tank 1 containing suspended solids in the reaction solution is taken out by the pump 2 to the horizontal screw centrifuge 3, and enters the drum 11 through the feed pipe 7, and the strong centrifugal force generated by the high-speed rotating drum 11 makes the The solid phase settles to the inner wall net 12 of the drum, and the relative motion of the conveying screw 10 and the drum 11 is caused by the different rotation speed, so that the solid phase flows out of the slag car 4 from the sink 15, and the liquid phase flows from th...

Embodiment 2

[0032] (1) Feed according to 10mol n-butyraldehyde, formaldehyde, n-butyraldehyde, and calcium hydroxide are fed according to 3.2:1:0.8, (calcium hydroxide content is 90%) to obtain the reaction liquid for separation, start the screw centrifuge to rotate at 3500 turn / min. The centrifugation is clear mother liquor, and the impurity removal rate is 99%, and the specific operations are the same as in Example 1;

[0033] (2) The centrifuged mother liquor enters the concentration tower for evaporation, and calcium formate is separated during the concentration process, and the trihydric solution is subjected to rectification in the light component separation tower, and finally trihydric is distilled in the trihydric separation tower to obtain trihydric. 2.101 kg of trimethylolpropane with a mass content of 99.5% was obtained, and the yield in terms of n-butyraldehyde was 84.2%.

Embodiment 3

[0035] (1) Feed according to 10mol n-butyraldehyde, formaldehyde, n-butyraldehyde, and calcium hydroxide are fed according to 3.2:1:0.8, (calcium hydroxide content is 90%) to obtain the reaction liquid for separation, start the screw centrifuge to rotate at 4000 turn / min. The centrifugation is clear mother liquor, and the impurity removal rate is 99%, and the specific operations are the same as in Example 1;

[0036] (2) The centrifuged mother liquor enters the concentration tower for evaporation, and calcium formate is separated during the concentration process, and the trihydric solution is subjected to rectification in the light component separation tower, and finally trimethylolpropane is obtained by distillation in the trihydric separation tower. 2.053 kg of trimethylolpropane with a mass content of 99.5% was obtained, and the yield in terms of n-butyraldehyde was 82.2%.

[0037] Compared with the plate filter press separation method in Examples 1-3, the settling process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com