High fructose syrup triple-effect concentration evaporator

A three-effect evaporator and high-fructose syrup technology, which is applied in the direction of multi-effect evaporation, fructose production, glucose production, etc., can solve the problems of low efficiency and achieve the effect of high work efficiency and optimal utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

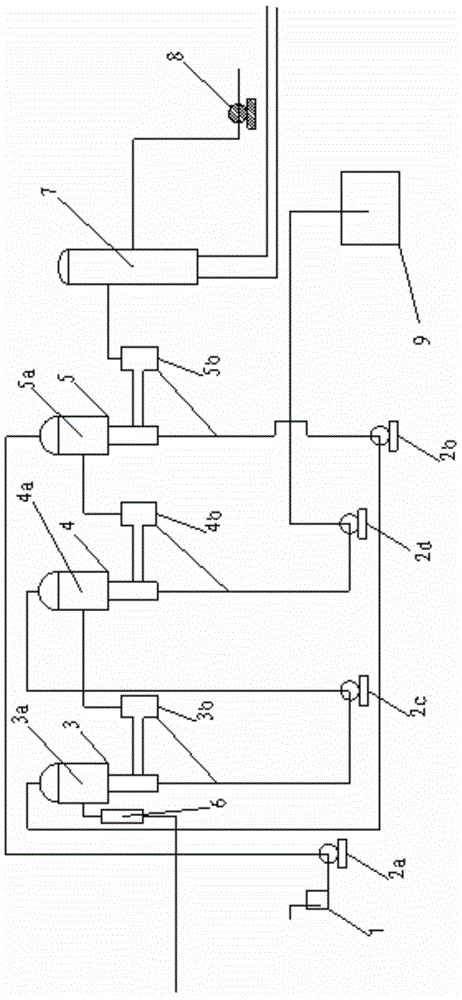

[0014] Embodiment: the three-effect evaporator of fructose syrup as shown in the figure is characterized in that it comprises three identical evaporators 3, a material tank 1, an air pump 6, a cooling water tower 7, a vacuum pump 8, and a finished product tank 9;

[0015] Each of the evaporators includes a reboiler and an evaporation chamber, and the lower part of the reboiler is connected to the evaporation chamber;

[0016] The inlet of the air pump 9 is connected with the steam inlet pipe, the outlet is connected with the first evaporator reboiler 3a, the top steam outlet of the first evaporation chamber 3b is connected with the second reboiler 4a, and the top steam of the second evaporation chamber 4b The outlet is connected with the third reboiler 5a, the top steam outlet of the third evaporation chamber 5b is connected with the cooling water tower 7, and the other side of the cooling water tower is connected with the vacuum pump 8;

[0017] The inlet of the material tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com