Ceramic ball and manufacture method thereof

A technology of ceramic balls and ball mills, applied in the field of ceramic materials, can solve the problems of toughness, poor strength, low mechanical properties of silicon nitride ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A ceramic ball, in parts by weight, the raw material is composed of 74 parts of silicon nitride powder, 2 parts of aluminum oxide powder, 7 parts of aluminum dihydrogen phosphate powder, 1 part of rare earth and 6 parts of nickel slag; wherein The nickel slag is composed of SiO 2 5 parts, MgO 1 part, Fe 2 o 3 0.5 parts, the balance being the oxides of Na, Ca, Cr and Ni; the powder diameter of the silicon nitride powder is 0.5 μm, the powder diameter of the aluminum oxide powder is 0.6 μm, and the powder diameter of the aluminum dihydrogen phosphate powder is 0.4 μm. μm.

[0026] Adding rare earth in this embodiment can effectively optimize the microstructure, thereby significantly improving the toughness and strength of silicon nitride ceramics; adding nickel slag can reduce production costs, comprehensively utilize nickel slag, and the prepared silicon nitride ceramics have mechanical properties High performance.

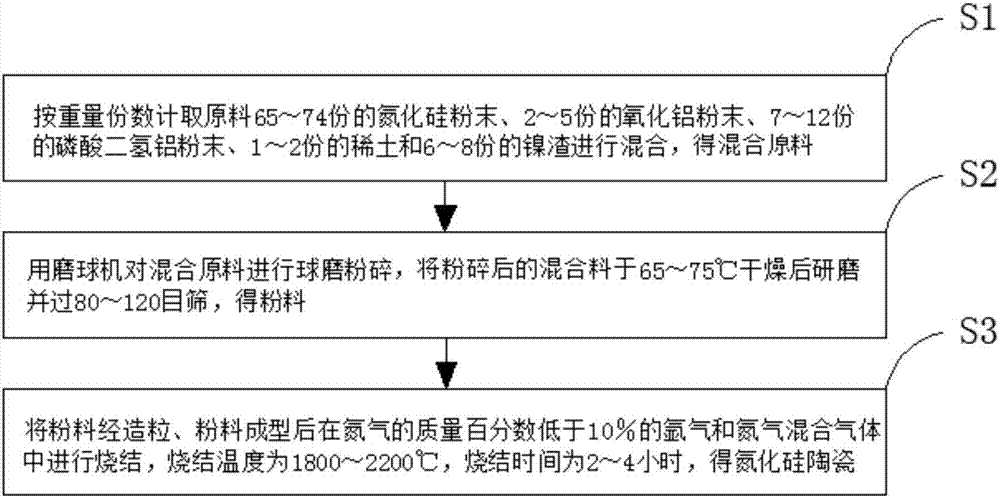

[0027] refer to figure 1 , a preparation method ...

Embodiment 2

[0033] A ceramic ball, in parts by weight, the raw material is composed of 65 parts of silicon nitride powder, 5 parts of aluminum oxide powder, 12 parts of aluminum dihydrogen phosphate powder, 2 parts of rare earth and 8 parts of nickel slag; The nickel slag is composed of SiO 2 3 parts, MgO 2 parts, Fe 2 o 3 1 part, the balance is the oxide of Na, Ca, Cr and Ni; The powder diameter of described silicon nitride powder is 1.5 μ m, the powder diameter of aluminum oxide powder is 1.2 μ m, the powder diameter of aluminum dihydrogen phosphate powder is 0.7 μm.

[0034] Adding rare earth in this embodiment can effectively optimize the microstructure, thereby significantly improving the toughness and strength of silicon nitride ceramics; adding nickel slag can reduce production costs, comprehensively utilize nickel slag, and the prepared silicon nitride ceramics have mechanical properties High performance.

[0035] Its preparation method comprises the following steps:

[003...

Embodiment 3

[0041] A ceramic ball, in parts by weight, the raw material is composed of 70 parts of silicon nitride powder, 3 parts of aluminum oxide powder, 10 parts of aluminum dihydrogen phosphate powder, 1.5 parts of rare earth and 7 parts of nickel slag; The nickel slag is composed of SiO 2 4 parts, MgO 1.5 parts, Fe 2 o 30.8 parts, the balance being the oxides of Na, Ca, Cr and Ni; the powder diameter of the silicon nitride powder is 1 μm, the powder diameter of the aluminum oxide powder is 0.8 μm, and the powder diameter of the aluminum dihydrogen phosphate powder is 0.5 μm .

[0042] Adding rare earth in this embodiment can effectively optimize the microstructure, thereby significantly improving the toughness and strength of silicon nitride ceramics; adding nickel slag can reduce production costs, comprehensively utilize nickel slag, and the prepared silicon nitride ceramics have mechanical properties High performance.

[0043] Its preparation method comprises the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com