Solid-liquid mixing equipment for preparing ultra-fine slurry and mixing method of solid-liquid mixing equipment

A solid-liquid mixing and equipment technology, which is applied in the field of solid-liquid mixing equipment for preparing ultrafine slurry, can solve the problems of inability to grind and refine materials, long process, complicated production process and equipment, etc. Easy to use and increase the grinding time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

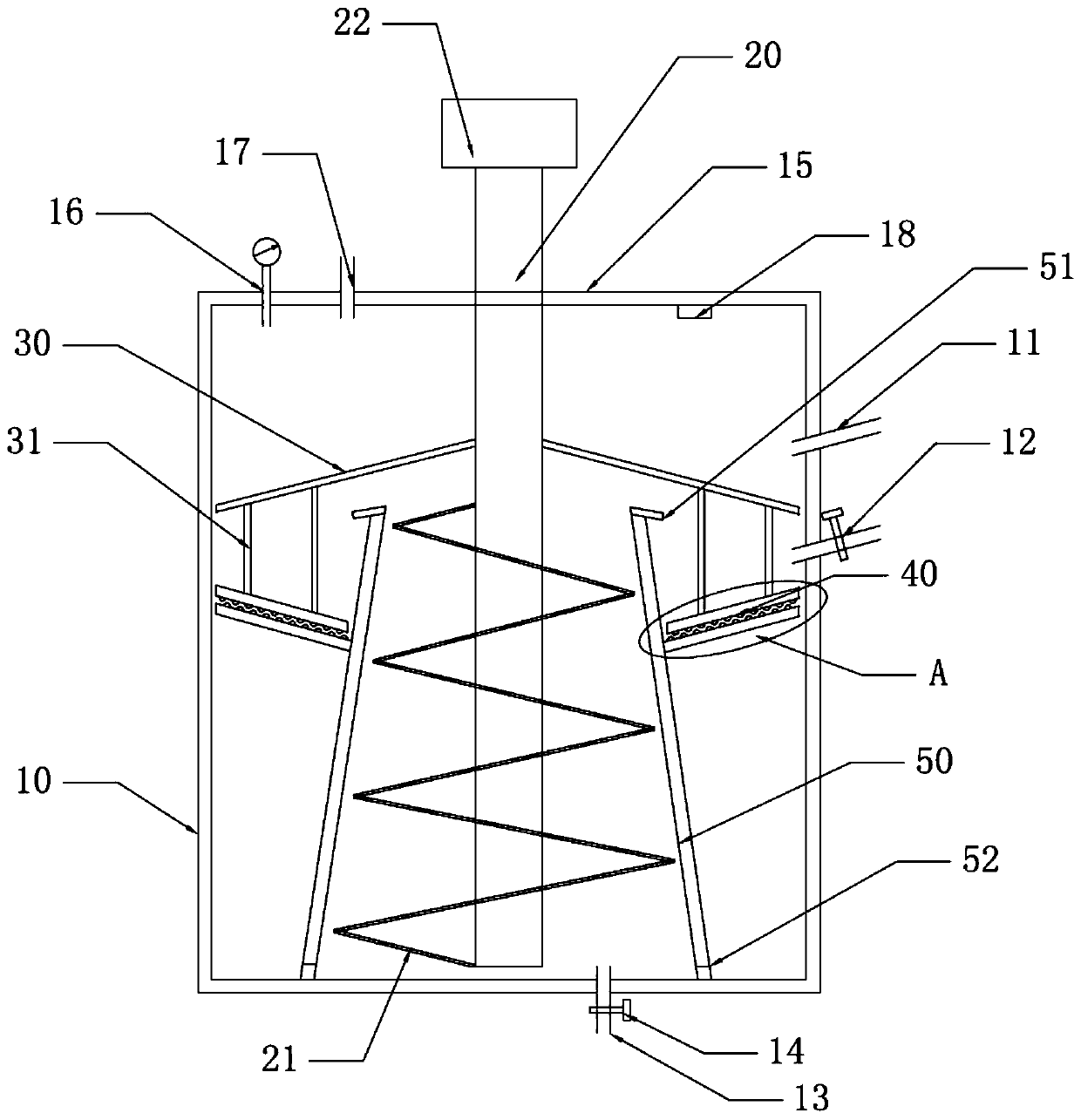

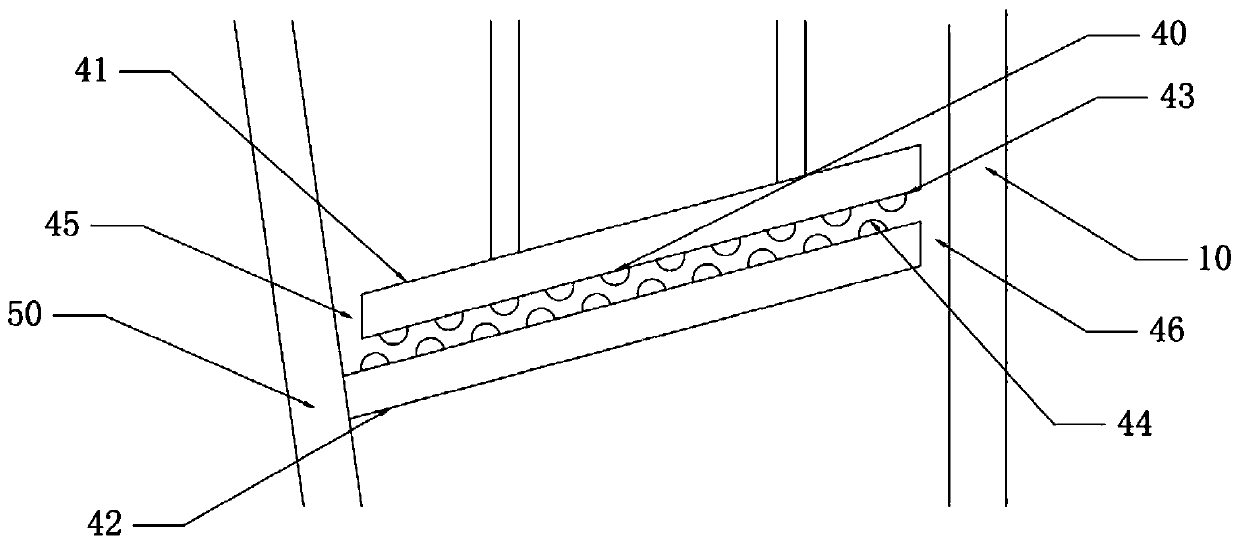

[0033] Example: such as Figure 1-3 As shown, a solid-liquid mixing equipment for preparing ultrafine slurry includes a dispersion cylinder 10, a rotating shaft 20, a grinding mechanism 40 and a fixed sleeve 50. The dispersion cylinder 10 includes an upper cover 15, a lower cover, and On the side wall between the upper cover and the lower cover, the dispersion cylinder 10 is provided with a liquid inlet 11, a solid inlet 12 and a discharge outlet 13;

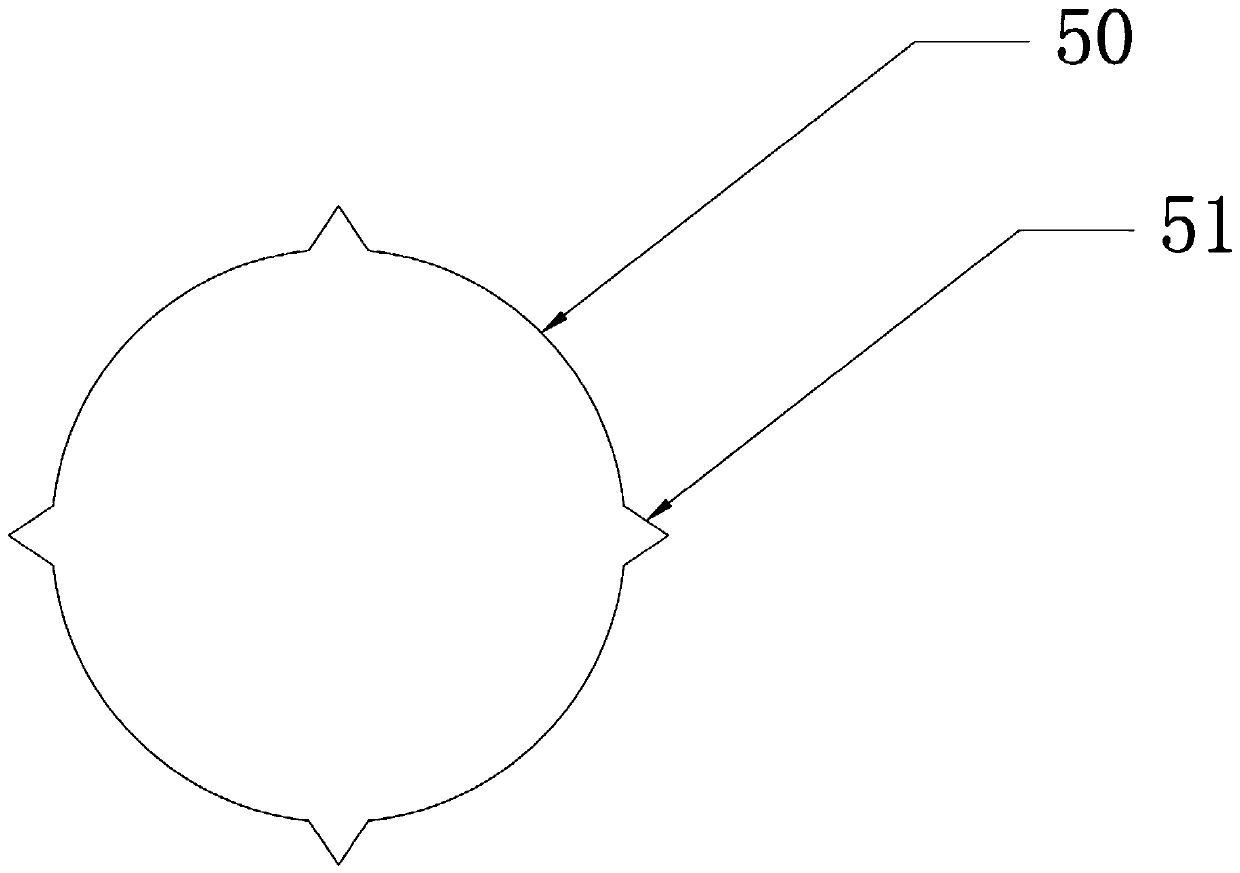

[0034] Wherein, the rotating shaft 20 is located in the dispersion cylinder and its upper end extends from the dispersion cylinder to be connected to the drive mechanism 22. In this embodiment, the drive mechanism is a motor, and the fixed sleeve 50 is located in the dispersion cylinder. It is fixedly connected to the bottom of the dispersion cylinder 10. There are several feeding through holes 52 near the bottom of the fixed sleeve 50 to facilitate the material to enter the inside of the fixed sleeve. There are several overflow po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com