Novel powdery cement grinding aid and preparation method thereof

A cement grinding aid and powder technology, which is applied in the field of new powder cement grinding aid and its preparation, can solve the problems of powder cement grinding aid with many ingredients, cement strength enhancement effect is not obvious, and cement clinker consumption is large To achieve the effect of increasing the economic benefits of the enterprise, reducing the power consumption of grinding, and reducing the fineness of powder particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

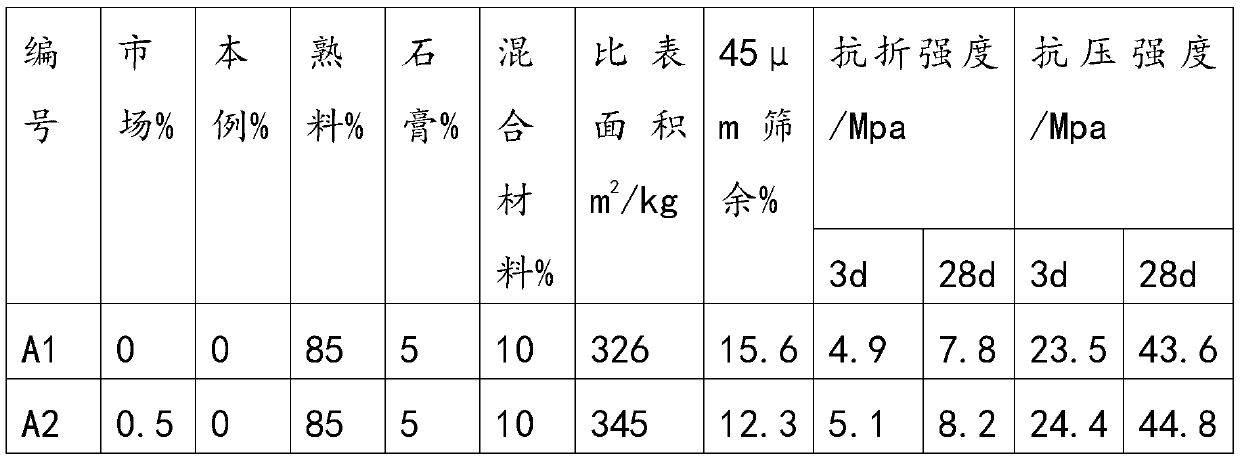

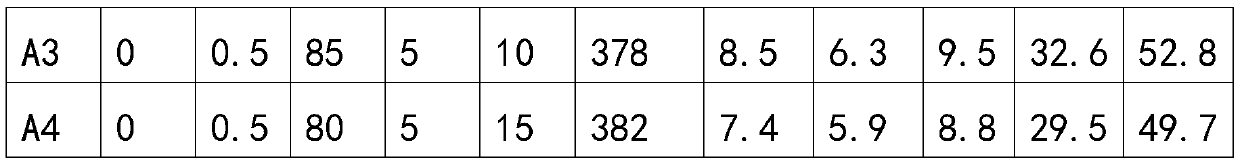

Examples

Embodiment 1

[0021] The preparation method of the new powder cement grinding aid: Weigh 1kg of diethanol monoisopropanolamine raw material into the special reaction kettle, slowly add 1kg of hydrochloric acid while stirring, and control the addition time of hydrochloric acid within 10-15min Completed, after the addition of hydrochloric acid is completed, stir for another 10-15min to obtain a surfactant.

[0022] Weigh 1 kg of the above-mentioned surfactant and add it to 1 kg of water and stir evenly, then add 0.04 g of foaming agent under stirring until it is completely dissolved, and continue stirring for 5-10 minutes until it is uniform to obtain a synergistic solution.

[0023] Take by weighing 4.85kg of fly ash and 3kg of Yuanming powder and add them to the blender and stir well, then add 0.15kg of the above-mentioned synergist, mash the block formed after adding the synergist, and stir well, Then add 2.0kg of sulphoaluminate cement and stir well to obtain powder cement grinding aid. ...

Embodiment 2

[0030] The preparation method of the new powder cement grinding aid: Weigh 3kg of diethanol monoisopropanolamine raw material into the special reaction kettle, slowly add 2kg of hydrochloric acid while stirring, and control the addition time of hydrochloric acid within 10-15min Completed, after the addition of hydrochloric acid is completed, stir for another 10-15min to obtain a surfactant.

[0031] Weigh 1 kg of the above-mentioned surfactant and add it to 1 kg of water and stir evenly, then add 0.04 g of foaming agent under stirring until it is completely dissolved, and continue stirring for 5-10 minutes until it is uniform to obtain a synergistic solution.

[0032] Weigh 4.0kg of fly ash and 3.5kg of Yuanming powder, add them to the mixer and stir well, then add 0.2kg of the above-mentioned synergist, mash the block formed after adding the synergist, and stir well , then add 2.3kg of sulphoaluminate cement, and stir well to get the powder cement grinding aid.

[0033] Mix ...

Embodiment 3

[0038]The preparation method of the new powder cement grinding aid: Weigh 2kg of diethanol monoisopropanolamine raw material into the special reaction kettle, slowly add 1kg of hydrochloric acid while stirring, and control the addition time of hydrochloric acid within 10-15min Completed, after the addition of hydrochloric acid is completed, stir for another 10-15min to obtain a surfactant.

[0039] Weigh 1 kg of the above-mentioned surfactant and add it to 1 kg of water and stir evenly, then add 0.04 g of foaming agent under stirring until it is completely dissolved, and continue stirring for 5-10 minutes until it is uniform to obtain a synergistic solution.

[0040] Weigh 6.0kg of fly ash and 2.5kg of Yuanming powder, add them to the mixer and stir well, then add 0.1kg of the above-mentioned synergist, mash the block formed after adding the synergist, and stir well , then add 1.4kg of sulphoaluminate cement, and stir well to get the powder cement grinding aid.

[0041] Mix 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com