Preparation method for graphene

A graphene and graphite technology, applied in the field of graphene preparation, can solve the problems of small output and incapable of large-scale production, and achieve the effects of low cost, large industrial application potential, and increased application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

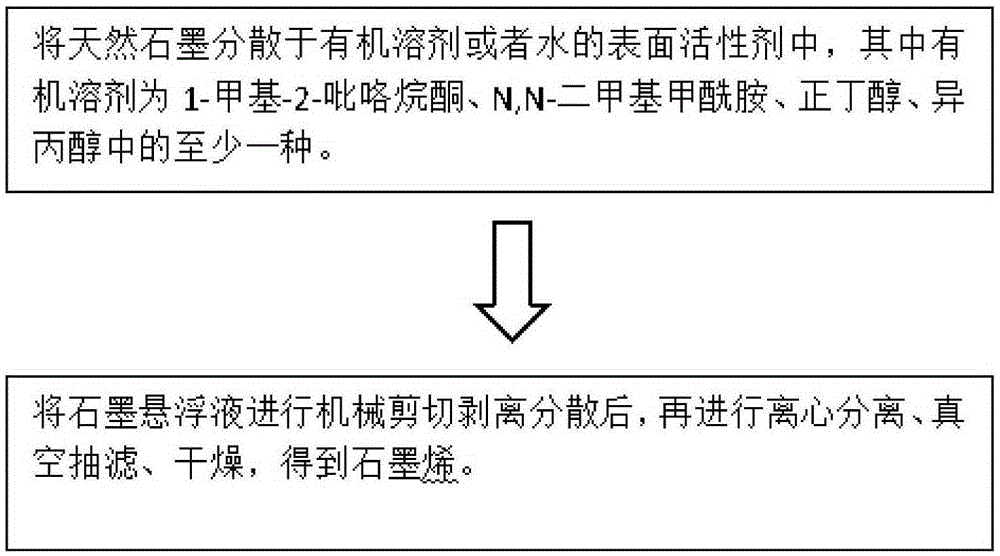

Method used

Image

Examples

Embodiment 1

[0026] The first step is according to the proportional relationship in table 1, and 10g natural graphite is dispersed in the organic solvent 1-methyl-2-pyrrolidone (NMP) of 500ml, obtains the graphite suspension that concentration is 20g / l, the carbon content of natural graphite It is more than 98% graphite powder.

[0027] In the second step, shear the obtained graphite suspension in a colloid mill for 5 minutes. The colloid mill is a JM-5 emulsified asphalt testing machine with a pressure of 0.1 MPa, and then take out the sheared graphite suspension.

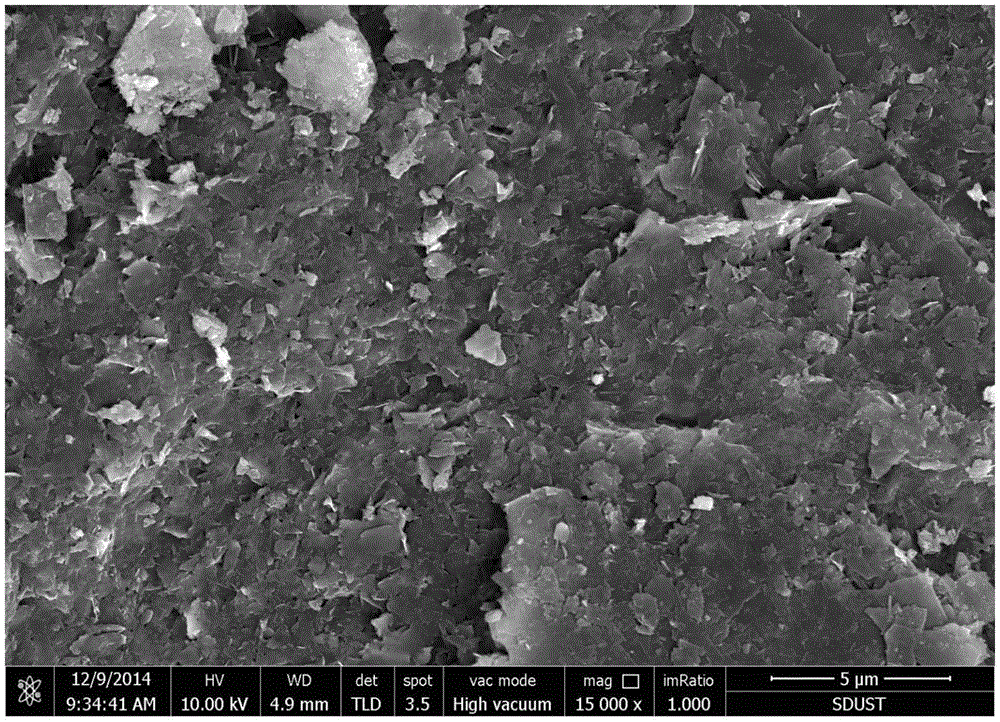

[0028] In the third step, the prepared graphite suspension is centrifuged at a rotational speed of 500 rpm and a centrifugation time of 10 min. The supernatant is collected, and then the supernatant is vacuum filtered and dried to obtain graphene. The quality, concentration, yield and efficiency of the graphene it prepares are shown in Table 2, as figure 2 It is shown that the graphene monolayer structure prepared by the pre...

Embodiment 2

[0030] The first step is to disperse 30 g of natural graphite into 500 ml of organic solvent 1-methyl-2-pyrrolidone (NMP) according to the ratio in Table 1 to obtain a graphite suspension with a concentration of 60 g / l.

[0031] The second step is the same as the second step in Example 1.

[0032] The third step is the same as the third step in Example 1. The quality, concentration, yield and efficiency of the prepared graphene are shown in Table 2.

Embodiment 3

[0034] The first step is according to the proportion relationship in table 1, and 1.8g natural graphite is dispersed in the surfactant sodium dodecylbenzene sulfonate solution of the water of 600ml, obtains the graphite suspension that concentration is 3g / l, wherein twelve The ratio of the concentration of sodium alkylbenzene sulfonate to the concentration of initial graphite is 1 / 8.

[0035] In the second step, the obtained graphite suspension is poured into a colloid mill for mechanical shearing for 5 minutes at a pressure of 0.1 MPa, and then the sheared graphite suspension is taken out.

[0036] The third step is to centrifuge the prepared graphite suspension (the centrifugal speed is 1000 rpm, and the centrifugation time is 10min) to keep the supernatant, and then vacuum filter, wash and dry the supernatant to obtain graphene . The quality, concentration, yield and efficiency of the prepared graphene are shown in Table 2.

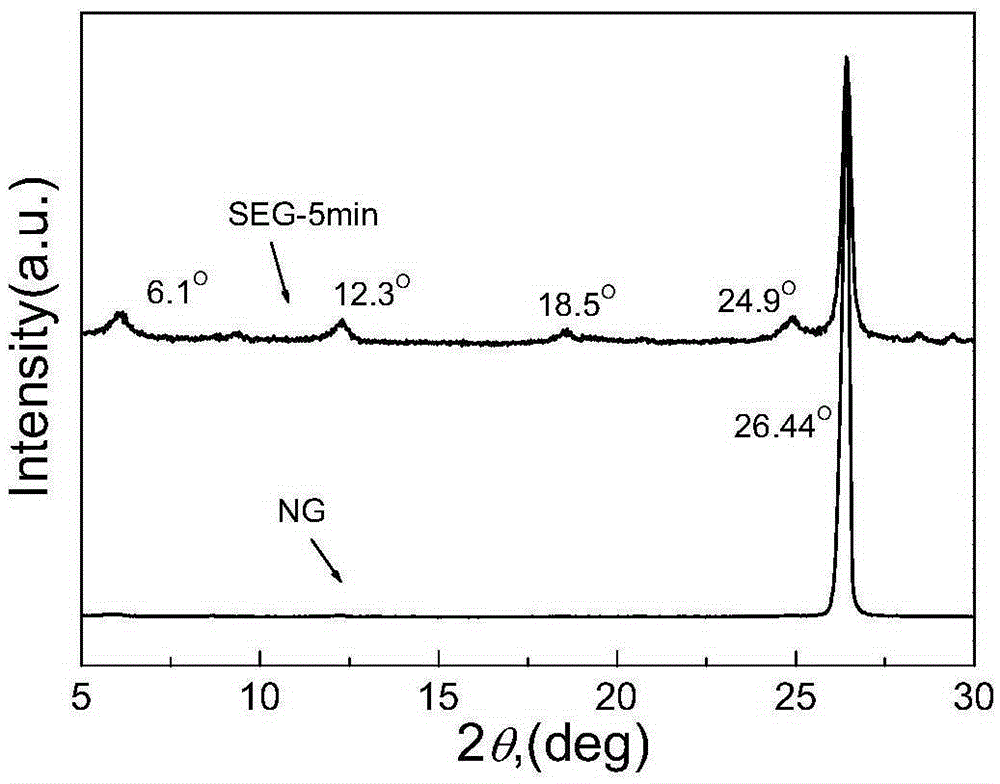

[0037] like image 3 As shown, the XRD image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com