Roll grinding machine grinding in circulating way

A technology of circular grinding and grinding machine, which is applied in the field of machinery, can solve problems such as high cost and complex structure, and achieve the effect of high automation and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

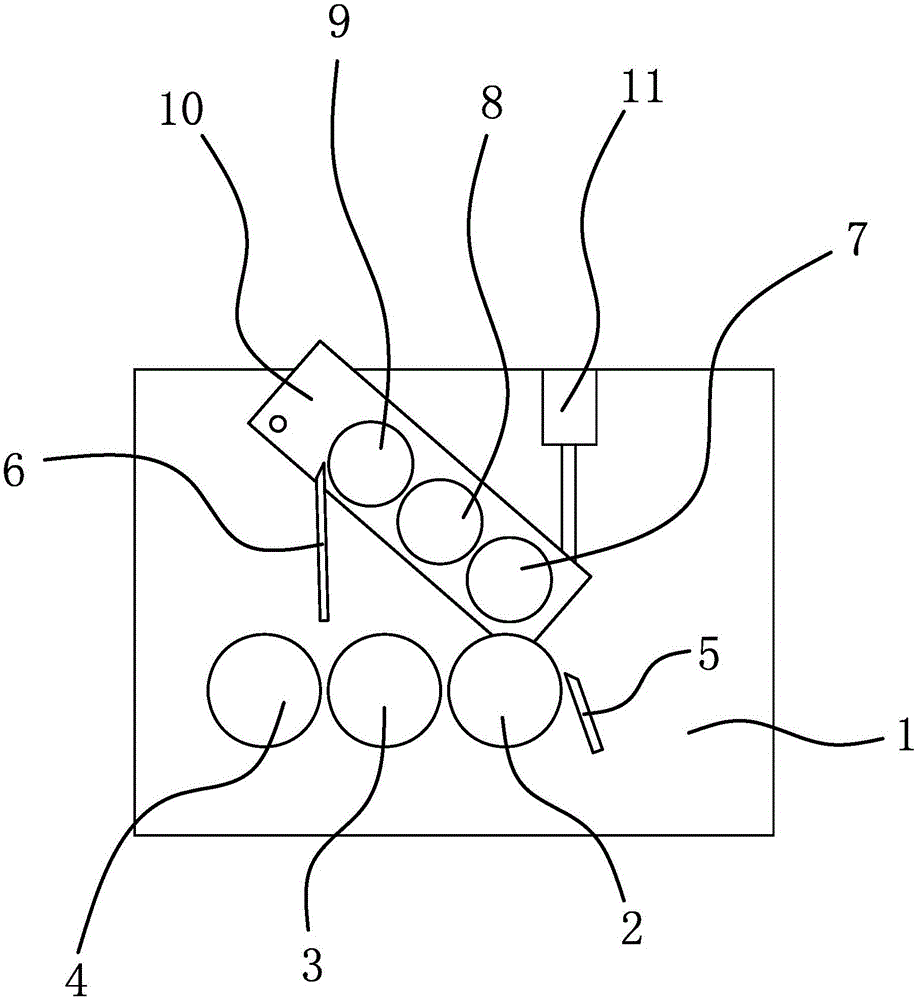

[0050] Such as figure 1 As shown, the roller grinder for this circular grinding includes a frame 1, a front roller 2, a middle roller 3 and a rear roller 4, and the above-mentioned front roller 2, middle roller 3 and rear roller 4 are all axially fixed on the frame 1 The above-mentioned front roller 2, middle roller 3 and rear roller 4 are arranged in parallel in the horizontal direction and there is a gap for the passage of ink or slurry between two adjacent rollers. The above-mentioned front roller 2, middle roller 3 and rear roller 4 A grinding part for grinding ink is formed, and an ink transfer mechanism is also connected to the frame 1, and the ink transfer mechanism is located on the upper part of the grinding part, and the front roller 2 has a scraper 5 for collecting ink or slurry There is a scraper 2 6 between the rear roller 4 and the middle roller 3, and the edge of the scraper 6 is close to the ink transfer mechanism, and the ink or slurry at the ink transfer mech...

Embodiment 2

[0064] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that:

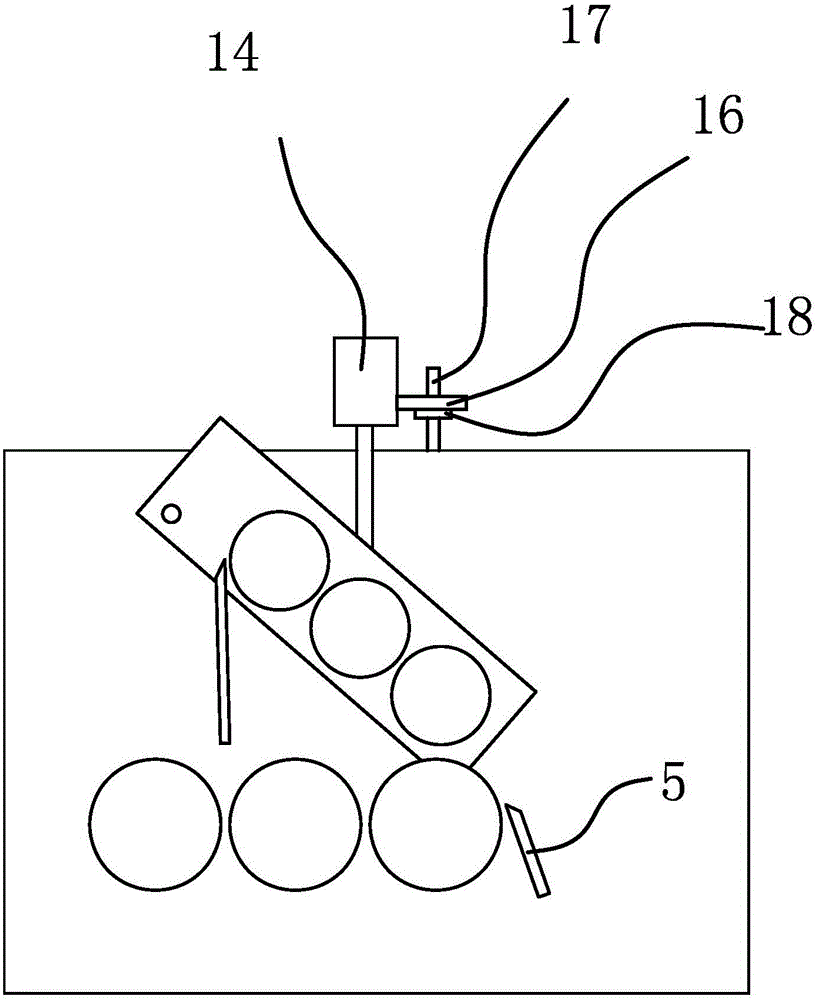

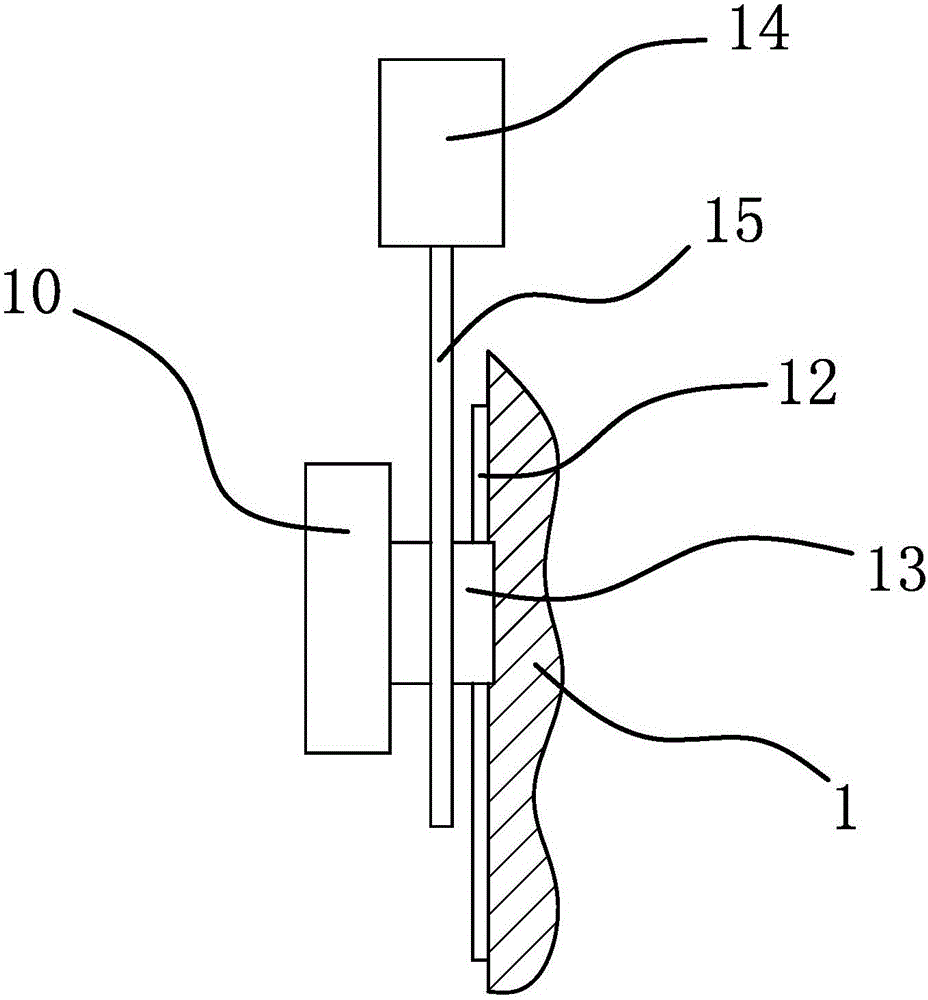

[0065] Such as figure 2 with image 3 with Figure 4 Shown, described frame 1 has an ink transfer frame 10, above-mentioned ink transfer roller one 7, ink transfer roller two 8 and ink transfer roller three 9 are all axially fixed on the ink transfer frame 10, the machine Also have the guide rail 12 that vertical direction is arranged on the frame 1, have the slide block 13 that is embedded in above-mentioned guide rail 12 places on the above-mentioned ink transfer frame 10, also have a motor 14 on the described frame 1, be fixedly connected with on the motor 14 rotating shafts A threaded mandrel 15 parallel to the guide rail 12, the slider 13 is sleeved on the threaded mandrel 15 and the two are screwed together.

[0066] The motor 14 is fixedly connected to an adjustment block 16 , and there is a gap adjustment mechanism between the adjustment b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com