Wood round rod grinding forming machine and wood round rod machining method

A molding machine, round bar technology, applied in metal processing equipment, grinding/polishing equipment, grinding machines, etc., can solve the problems of incomplete product shape, high production cost, low production efficiency, etc., and prolong the grinding time. , The effect of prolonging the grinding time and improving the efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

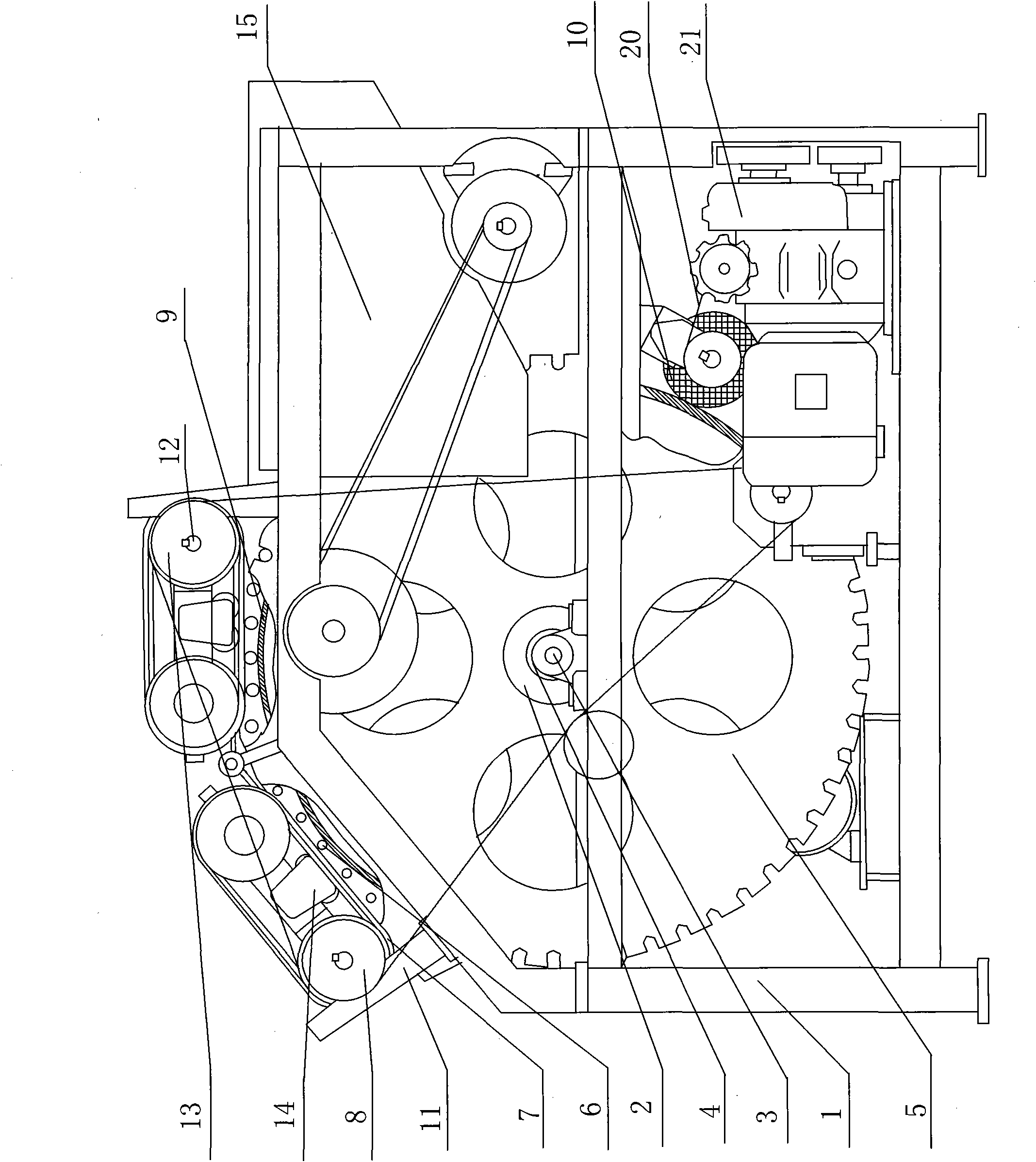

[0031] Wooden round rod grinding forming machine, which consists of: a frame 1 fixed with a charging box 15, a main shaft 3 is installed on the beam of the frame, the main shaft 3 is covered with an outer shaft 4, and the outer shaft 4 Connected to the sheave 5 passing through the outer shaft, the motor 21 in the frame 1 is connected to the friction wheel 10 through the V-belt 20, and the friction wheel 10 contacts the supporting wheel 9; the supporting wheel 9 is located on both sides between 5 sheaves. Tape wheel 8 is housed on the frame above described sheave 5 and described supporting wheel 9, and the adhesive tape 13 between described tape wheel will be pressed on described supporting wheel 9 by processed bar, and described The side of the grooved wheel 5 is provided with a driving grinding wheel group, that is, each grinding wheel of the grinding wheel group is connected to a corresponding driving motor.

[0032] The sheave 5 is located on one side of the processing rod...

Embodiment 2

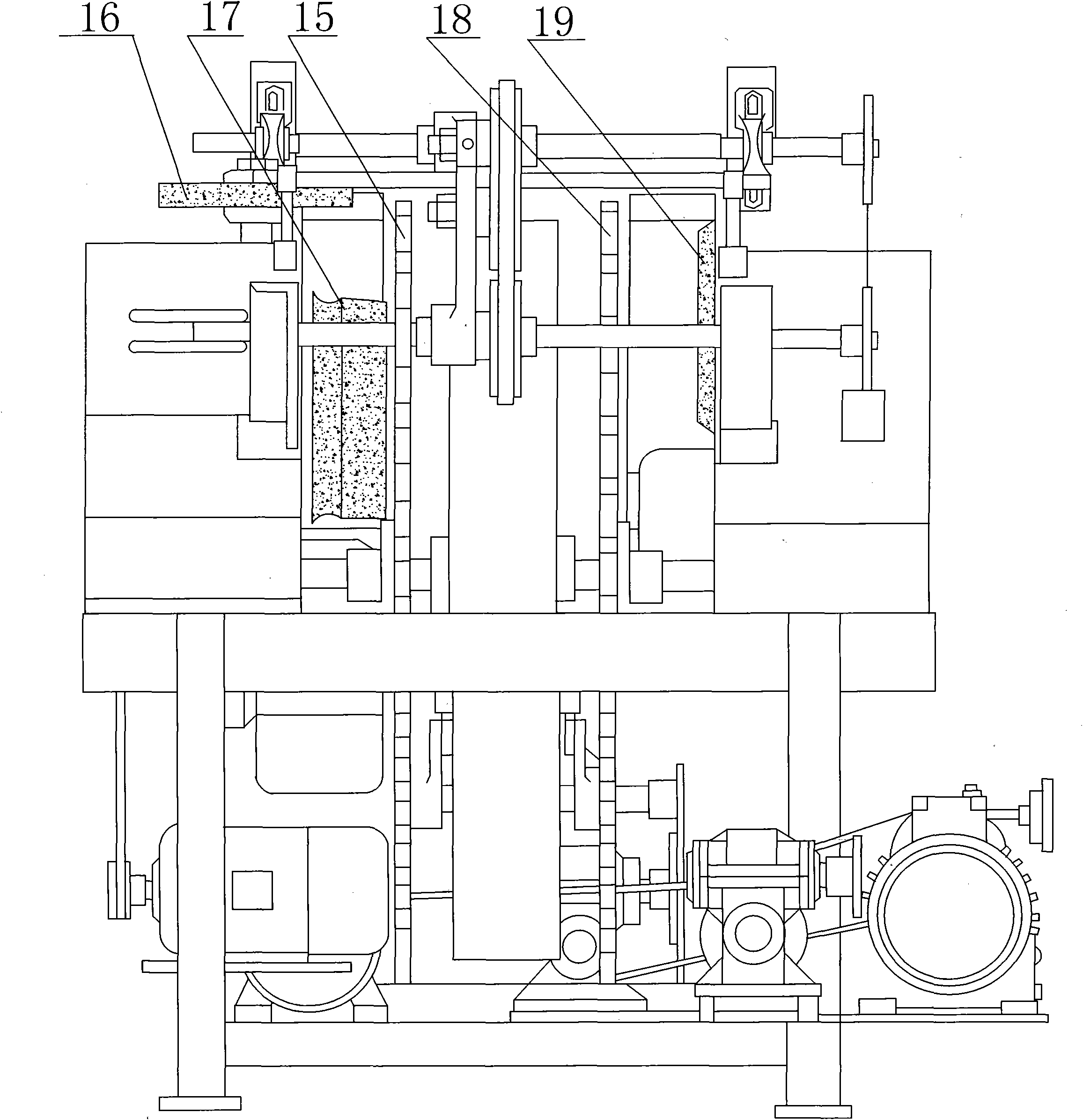

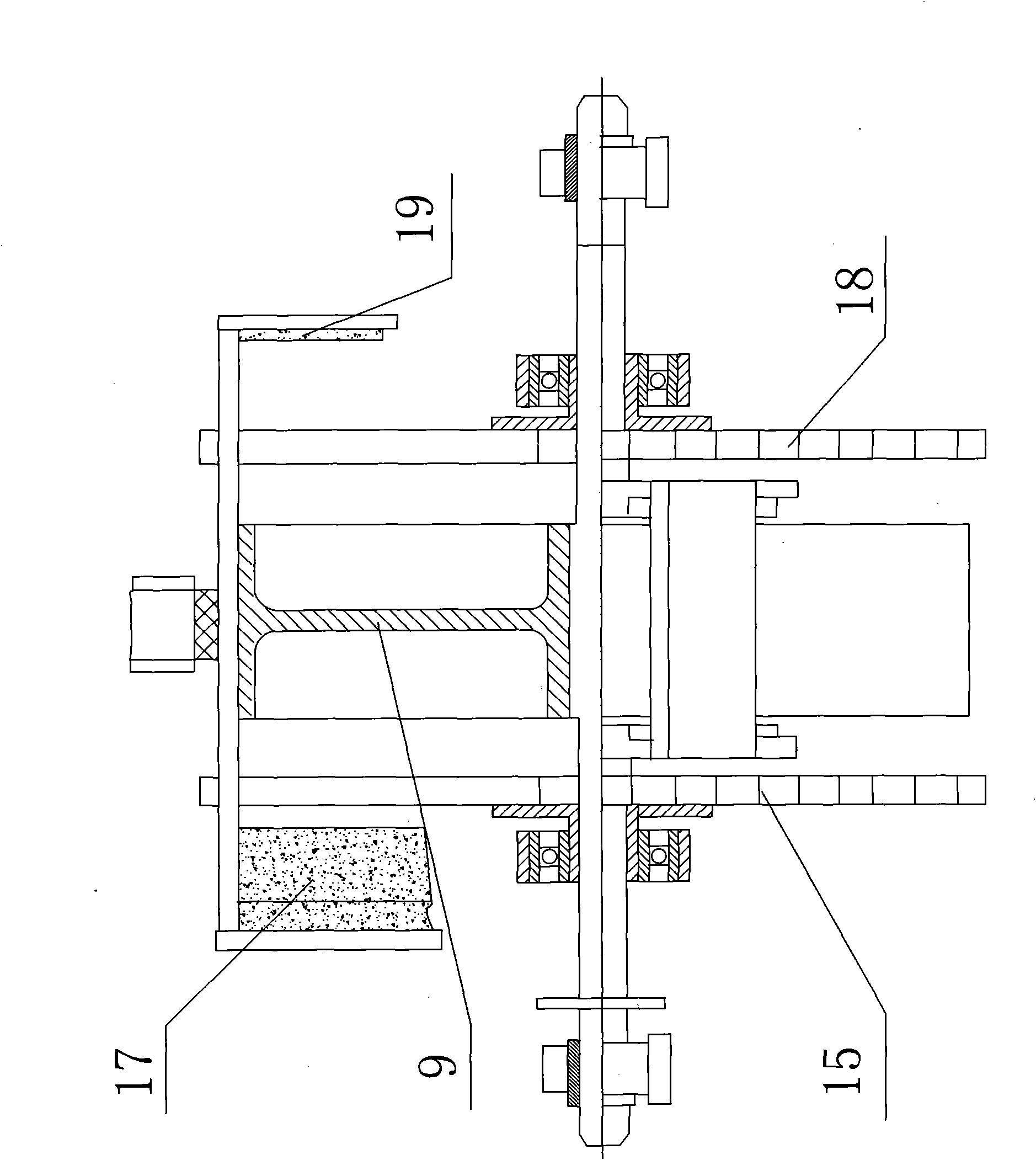

[0035] In the wooden round rod grinding machine described in Embodiment 1, the grinding wheel set includes: the upper grinding wheel 16 above the left sheave 15, the left grinding wheel 17 on the side of the left sheave 15, the 19 right emery wheels on the right grooved wheel 18 sides.

Embodiment 3

[0037] The method of described forming machine processing wooden round bar:

[0038] The round rod rolls on the support wheel, and the rotation of the support wheel counter-rotating with the tape wheel drives the round rod to move in the opposite direction under the tape, offsetting part of the translational speed of the round rod caused by the tape and accelerating the rotation of the round rod;

[0039] The tip grinding and forming method: the round bar is on the supporting wheel, and the round bar is ground and formed by the left grinding wheel during rotation;

[0040]The grinding method of the semicircular head: there is a right grinding wheel at the end of the round rod, the tape and the supporting wheel drive the round rod to rotate, the right grinding wheel is driven by the motor, and the round rod is ground into a semicircular head by the right grinding wheel during rotation;

[0041] On the supporting wheel shaft, the tube shaft is sleeved on the outside of the shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com