Preparation equipment for cosmetic titanium dioxide

A technology of titanium dioxide and cosmetics, applied in the field of titanium dioxide preparation, can solve the problems of increased filtration burden, waste of raw materials, unfavorable separation of titanium dioxide and chlorine gas, etc., and achieve the effect of increasing filtration burden, reducing residue and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

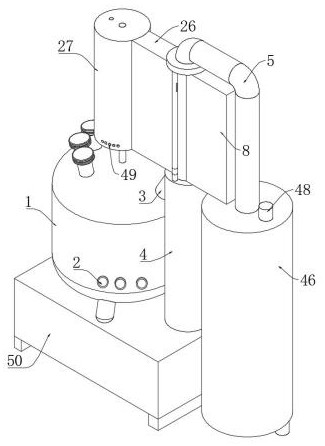

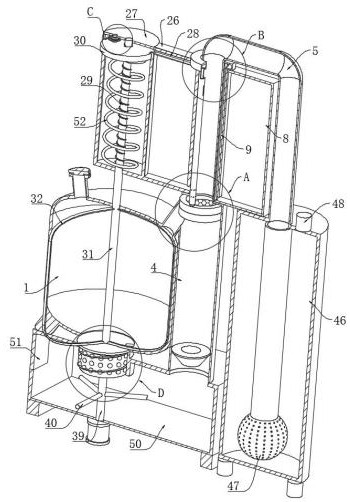

Image

Examples

Embodiment approach

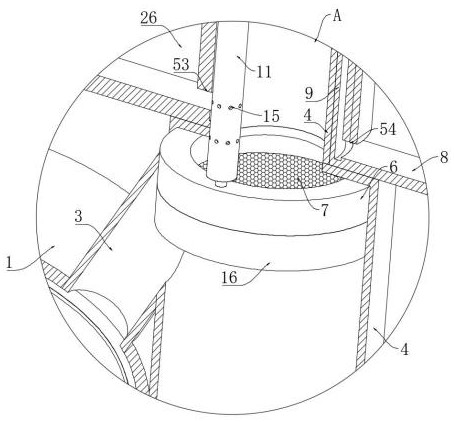

[0054] As an embodiment of the present invention, the pushing mechanism includes a sleeve 9 and a first vent 15, the sleeve 9 is sleeved on the outer ring of the second air outlet pipe 5, and a first liquid storage tank is fixed on one side of the sleeve 9 8. A second connection port 54 is provided through the bottom of the connection between the first liquid storage tank 8 and the sleeve 9, the top of the sleeve 9 is fixed with an annular connecting pipe 10, and the inner ring of the annular connecting pipe 10 is connected to the top of the sleeve 9. Two straight pipes 11 are symmetrically and fixedly connected to the bottom of the outer ring of the annular connecting pipe 10. The two straight pipes 11 are symmetrically arranged on both sides of the casing 9, and the interiors of the two straight pipes 11 are slidably connected with a first piston. 12. The bottoms of the two first pistons 12 are fixed with movable rods 13. The bottoms of the two movable rods 13 pass through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com