Preparation method for reaction type spice for cigarette and application of reaction type spice to cigarette

A reaction and fragrance technology, applied in the fields of application, essential oil/flavor, tobacco, etc., can solve the problems of large loss of aroma components, complicated operability, and long pretreatment time, so as to improve the quality of cigarettes and have strong operability , Aroma-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

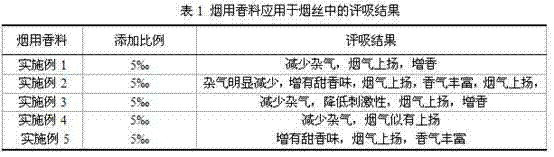

Examples

Embodiment 1

[0037] (1) Grind the tobacco powder (the tobacco powder in this example is from randomly collected tobacco leaves re-roasted or sieved tobacco leaves or shredded tobacco powder in the process of shredded cigarettes) to 10 meshes, and take 500 g of crushed tobacco powder and put it in a container Add 8000mL of water, disperse evenly, add potassium hydroxide to make the pH of the system 13, extract at 110°C for 0.5h, and obtain the extract;

[0038] (2) Adjust the pH value of the extract to 4.5 with citric acid, add ethanol until the volume concentration of ethanol in the system is 80%, reflux for extraction for 3 hours, and suction filter to obtain the supernatant;

[0039] (3) Concentrate the supernatant to a solid content of 60% by weight to obtain 260 g of the concentrate;

[0040] (4) Add 2g threonine, 0.6g glycine, and 15.6g glucose to the concentrated solution obtained in step (3), stir and dissolve evenly, adjust the pH value to 7 with sodium hydroxide, and react at 110°...

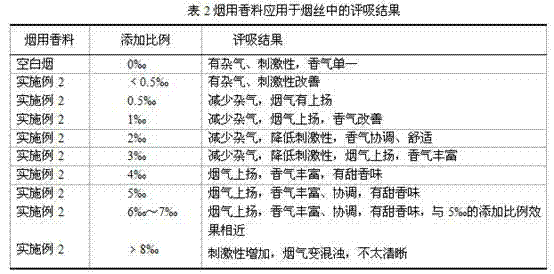

Embodiment 2

[0043] (1) Tobacco powder (the source is the same as in Example 1) is crushed to 80 mesh. Take 1000g of crushed tobacco powder and put it in a container, add 10000mL of water, disperse evenly, adjust the pH value to 10 with potassium hydroxide, and treat at 110°C 1.5h, to obtain the extract;

[0044] (2) Adjust the pH value of the extract to 4.5 with citric acid, add ethanol until the volume concentration of ethanol in the system is 60%, reflux for extraction for 3 hours, and suction filter to obtain the supernatant;

[0045] (3) Concentrate the supernatant until the weight content of the solids is 45%, and obtain 680g of the concentrate;

[0046] (4) Add 22g of threonine, 11g of glycine, 99g of xylose, and 99g of maltose to the concentrated solution obtained in step (3), stir and dissolve evenly, adjust the pH value to 7 with sodium hydroxide, and react at 130°C for 3 h; A liquid dark brown viscous tobacco flavor was obtained with a yield of 91.1%.

[0047] The tobacco flavor...

Embodiment 3

[0050] (1) Crush the tobacco powder to 100 mesh, take 1200g of tobacco powder and put it in a container, add 7200mL of water, stir to make it evenly dispersed, adjust the pH value to 8 with sodium hydroxide, and treat at 130°C for 4.5h to obtain the extract;

[0051] (2) Adjust the pH value of the extract to 6.5 with citric acid; add ethanol until the volume concentration of ethanol in the system is 70%, reflux for extraction for 3 hours, and suction filter to obtain the supernatant;

[0052] (3) Concentrate the supernatant to a solid content of 50% by weight to obtain 820 g of the concentrate;

[0053] (4) Add 10g of arginine, 10g of glycine, 20g of threonine, 72g of glucose, 36g of maltose, and 36g of fructose to the concentrated solution obtained in step (3), stir and dissolve evenly, and adjust the pH value to 8 with potassium hydroxide. Reaction at 130°C for 2 hours; a liquid dark brown viscous tobacco flavor was obtained with a yield of 83.67%;

[0054] The tobacco ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com