Method for synthesizing pyrroloquinoline quinone through lactobacillus fermentation

A technology for pyrroloquinoline quinone and lactic acid bacteria fermentation, applied in the field of microbial fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

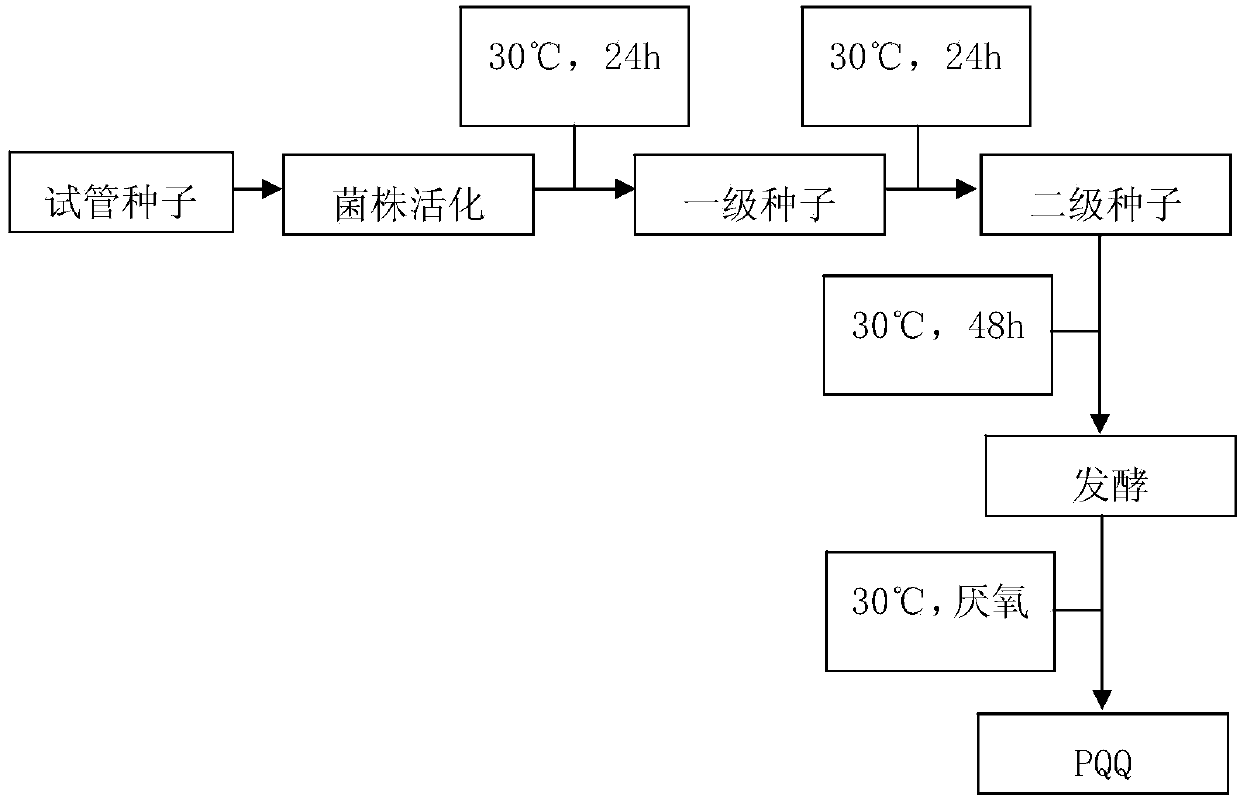

[0057] Such as figure 1 Shown, the present invention synthesizes the method for pyrroloquinoline quinone by lactic acid bacteria fermentation, comprises the following steps:

[0058] (1) Lactobacillus plantarum PQQ-1 was purchased from Jiaxing Yuanke Biotechnology Co., Ltd. with the product number YK-S-003.

[0059] (2) Each culture medium was prepared according to the following components, among which, the yeast extract and peptone were both Sigma products, and the barley flour was a product of Jinmaiyuan Mairenchang, Dafeng City, Jiangsu Province; other reagents were of analytical grade; After completion, all were sterilized at 121°C for 15 minutes; after preparation, all were sterilized at 121°C for 15 minutes;

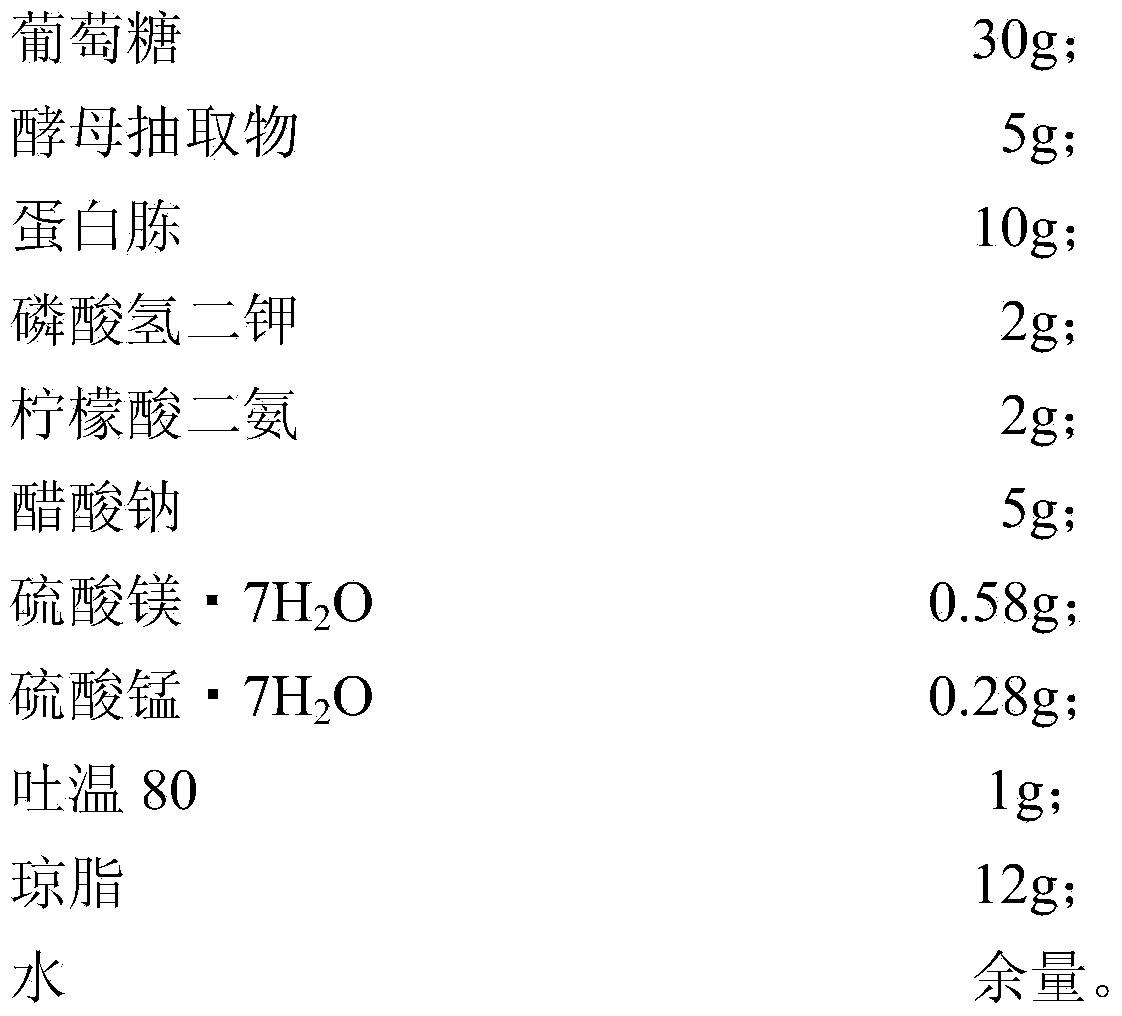

[0060] (a): 1L of MRS solid plate culture medium includes the following components by weight:

[0061]

[0062]

[0063] Adjust the pH to 6.5±0.2 with sulfuric acid.

[0064] (b): Agar subculture medium (A) is calculated in 1L, including the following comp...

Embodiment 2

[0090] Such as figure 1 Shown, the present invention synthesizes the method for pyrroloquinoline quinone by lactic acid bacteria fermentation, comprises the following steps:

[0091] (1) Each culture medium was prepared according to the following components. After the preparation was completed, they were all sterilized at 121°C for 15 minutes. The yeast extract and peptone were all Sigma products, and the barley flour was Jinmaiyuan wheat kernels from Dafeng City, Jiangsu Province. Chang products; other reagents are of analytical grade; after the preparation is completed, all are sterilized at 121°C for 15 minutes;

[0092] (a): Agar subculture medium (A) is calculated in 1L, including the following components by weight:

[0093]

[0094] And the agar subculture medium was adjusted to pH 6.8 with acid-base buffer.

[0095] (b): Activation medium (B) is calculated in 1L, including the following components by weight:

[0096]

[0097] And the activated medium was adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com