Preparation method of hydrogen type EUO (europium oxide) type molecular sieve

A molecular sieve and hydrogen-type technology, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of molecular sieve loss, large amount of waste water, time-consuming, etc., achieve the effect of reducing waste water treatment, reducing waste water discharge, and improving the final yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

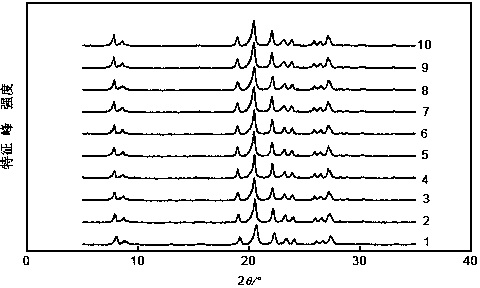

[0020] Add 4.60ml (25%wt) tetramethylammonium hydroxide, 2.1g hexamethyldiammonium bromide, 8.92ml (25%wt) ammonium silica sol, 0.59g (24%wt) aluminum isopropoxide to 5.0g water Stir evenly, put it into the kettle, put it at 175°C to react for 5 days, then filter, wash, dry at 110°C for 2 hours, and roast at 550°C for 5 hours to obtain a hydrogen-type EUO molecular sieve. The XRD spectrum is as attached figure 1 Shown in 1.

Embodiment 2

[0022] 3.7ml (25%wt) tetramethylammonium hydroxide, 6.12ml (33%wt) ethyl orthosilicate, 0.5g hexamethyldiammonium bromide, 0.24 (24%wt) aluminum isopropoxide, 1.0g water Stir evenly, put it into the kettle, put it at 185°C to react for 4 days, then filter, wash, dry at 110°C for 2 hours, and roast at 550°C for 5 hours to obtain hydrogen-type EUO molecular sieve. The XRD spectrum is as attached figure 1 Shown in 2.

Embodiment 3

[0024] Add 7.50ml (25%wt) tetraethylammonium hydroxide, 1.9g hexamethyldiammonium bromide, 7.15ml (25%wt) ammonium silica sol, 0.31g (24%wt) aluminum isopropoxide to 2.0g water Stir evenly, put it into the kettle, put it at 195°C to react for 2 days, then filter, wash, dry at 110°C for 2 hours, and roast at 550°C for 5 hours to obtain a hydrogen-type EUO molecular sieve. The XRD spectrum is as attached figure 1 Shown in 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com