Method for preparing nano cellulose from plant fibers

A technology of nano-cellulose and plant fiber, which is applied in the direction of pulping with acid acid/anhydride, washing/replacing pulp treatment liquid, etc., to shorten the process time, realize the effect of increasing the size and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

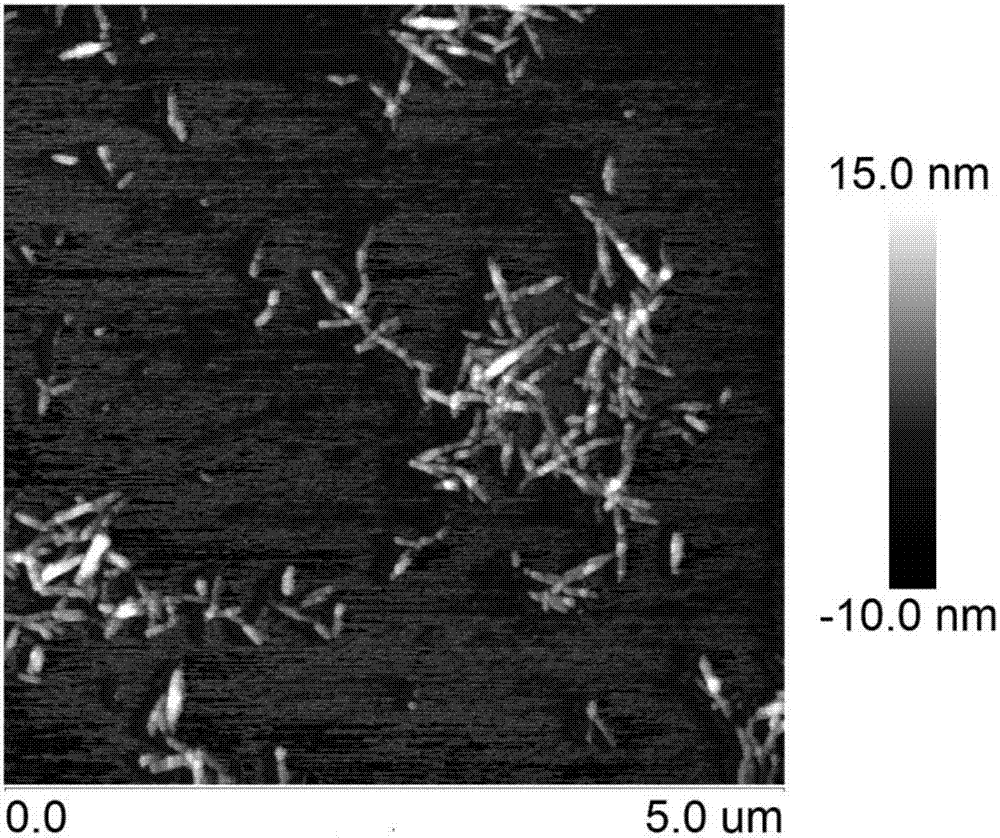

[0043] Weigh 10g of dry hardwood dissolving pulp fiber raw material into a three-necked flask, add 60ml of sulfuric acid with a mass concentration of 45%, put in a water bath at 55°C, pretreat for 20min, and then add 240ml of deionized water to terminate the reaction. Sulfuric acid was removed by centrifugal washing with deionized water for 4 times, and the washing liquid was collected, and unreacted sulfuric acid and cellulose-degraded sugar were collected by separation of sulfuric acid and carbohydrate nanofiltration separation membrane. The residual sulfuric acid in the pretreated solid obtained by centrifugation was neutralized with 0.1mol / L NaOH solution, adjusted to pH = 7, and then washed by centrifugation three times to remove the salt generated during the neutralization process. The concentration of the pretreated solid solution was adjusted to 5wt%. After a period of disc grinding, the disc grinding gap was 50 μm, and then a uniform and transparent nanocellulose suspe...

Embodiment 2

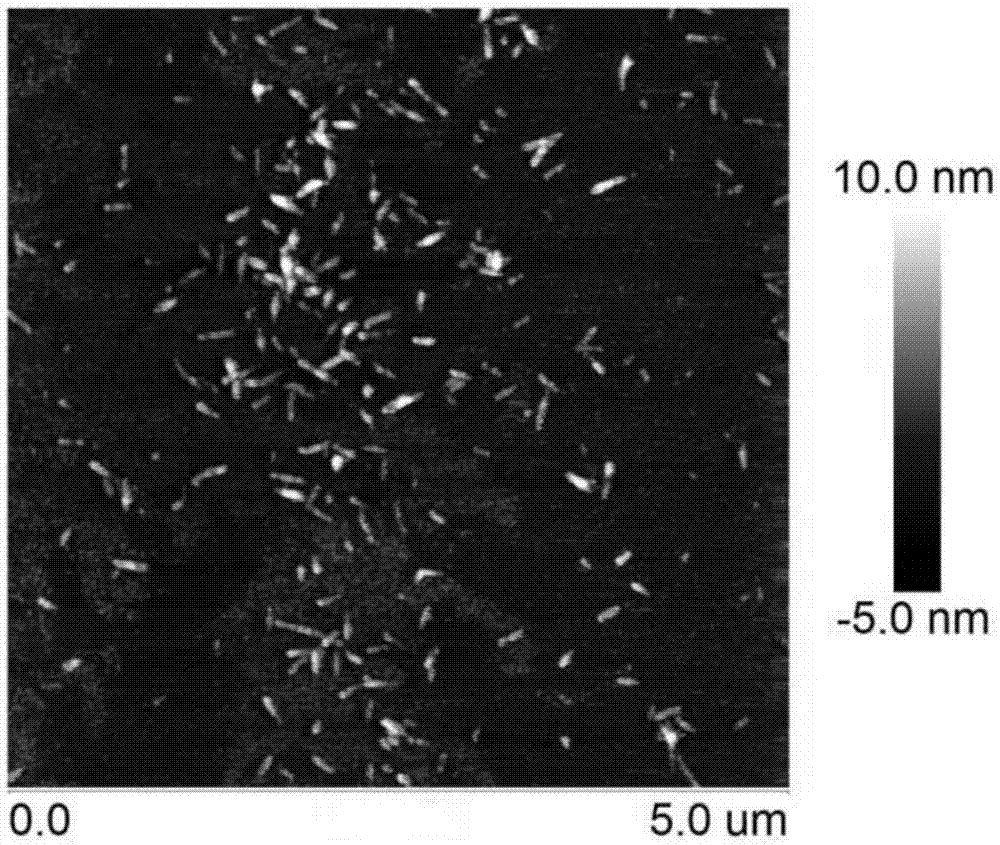

[0045] Weigh 10g of dry cotton pulp fiber raw material and place it in a three-necked flask, add 100ml of sulfuric acid with a mass concentration of 47%, put it in a water bath at 30°C, pretreat for 15min, and then add 600ml of deionized water to terminate the reaction. The sulfuric acid was removed by centrifugal washing with deionized water for 3 times, and the washing liquid was collected, and unreacted sulfuric acid and cellulose-degraded sugar were collected by separation of sulfuric acid and carbohydrate nanofiltration separation membrane. The residual sulfuric acid in the pretreated solid obtained by centrifugation was neutralized with 0.1mol / L KOH solution, adjusted to pH = 7, and then subjected to 2 centrifugal washings to remove the salt generated during the neutralization process. The concentration of the pretreated solid solution was adjusted to 10 wt%, and after a period of disc grinding, the disc grinding gap was 100 μm, and then a uniform and transparent nanocell...

Embodiment 3

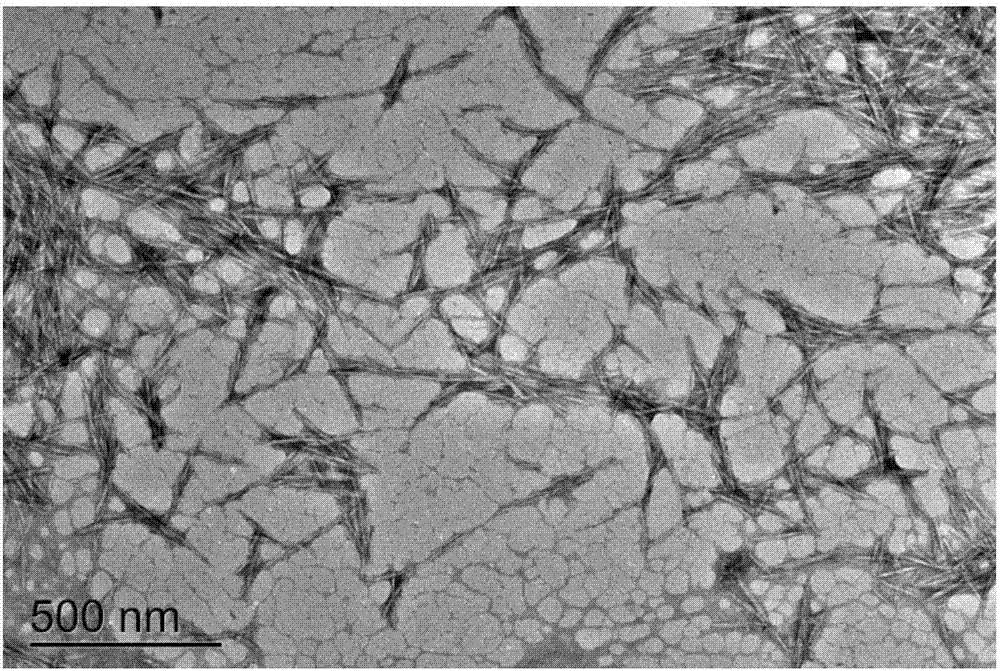

[0047]Weigh 10g of absolute dry bleached bagasse pulp fiber raw material and place it in a three-necked flask, add 80ml of sulfuric acid with a mass concentration of 50%, put it in a water bath at 40°C, pretreat for 10min, and then add 400ml of deionized water to terminate the reaction. The sulfuric acid was removed by centrifugal washing with deionized water for 3 times, and the washing liquid was collected, and unreacted sulfuric acid and cellulose-degraded sugar were collected by separation of sulfuric acid and carbohydrate nanofiltration separation membrane. The residual sulfuric acid in the pretreated solid obtained by centrifugation was neutralized with ammonia water, adjusted to pH = 7, and then subjected to 3 times of centrifugal washing to remove the salt generated during the neutralization process. The concentration of the pretreated solid solution was adjusted to 15 wt%. After a period of disc grinding, the disc grinding gap was 75 μm, and then a uniform and transpar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com