A method of extracting 1,5-pentanediamine from a 1,5-pentanediamine salt solution system

A technology for pentamethylenediamine salt and pentamethylenediamine is applied in the field of extracting 1,5-pentamethylenediamine, which can solve the problems of complex process, high cost, low recovery rate and the like, and achieves a simple process, simple operation and strong applicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

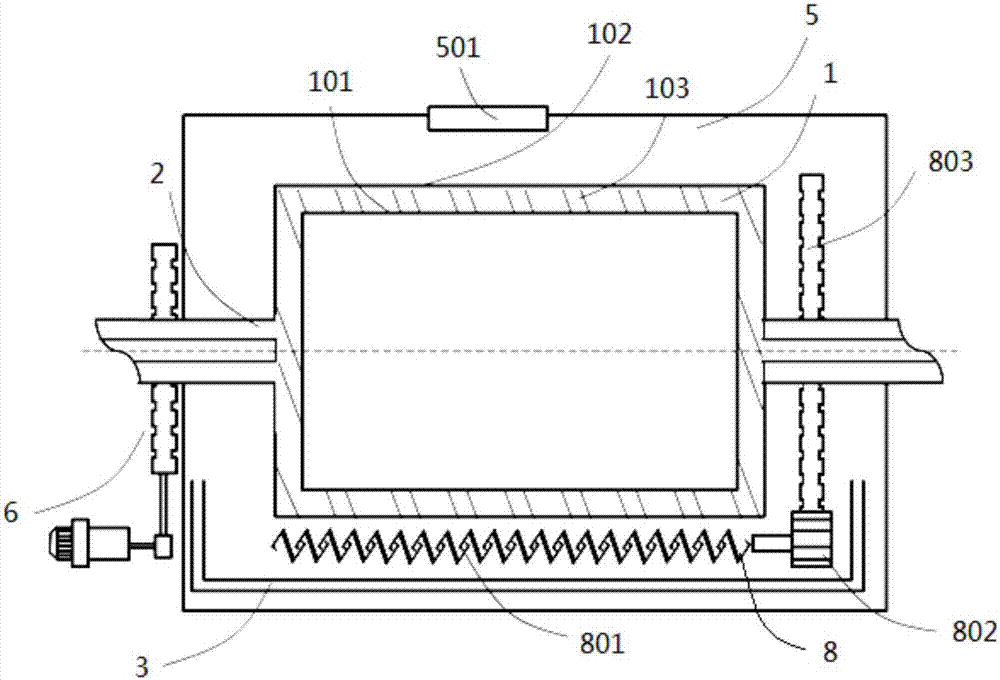

[0088] Get the 1,5-pentamethylenediamine salt enzyme conversion solution of the carrier (wherein, the mass percentage concentration of 1,5-pentamethylenediamine salt is 35%, the sulfate content of 1,5-pentamethylenediamine is 70%, phosphoric acid The content of salt is 10%, the percentage is the molar percentage of 1,5-pentamethylenediamine salt), calcium oxide powder (purity above 90%) is added, and the molar ratio of calcium oxide to 1,5-pentamethylenediamine salt is 1.1: 1. Stir at a temperature of 40°C for 2 hours; then feed into the vacuum scraper drying device of the present invention at a feed rate of 20kg / m 2 / h, the speed of the vacuum scraper drying device is 0.8rpm, the thickness of the scraping film is 1mm, and the temperature of the heat transfer oil is 200°C;

[0089] In the vacuum scraper drying device, the solution system obtained above was evaporated, and the evaporation was carried out under the conditions of a vacuum degree of -0.09 to -0.095 MPa and a tempe...

Embodiment 2

[0092] Take the 1,5-pentanediamine sulfatase conversion solution of the bacteria (wherein, the mass percent concentration of 1,5-pentanediamine salt is 30%), add calcium oxide, calcium oxide and 1,5-pentanediamine The molar ratio of amine salt is 1.2:1, stirring at 40°C for 1.5h; then feeding into the vacuum scraper drying device of the present invention, the feeding speed is 18kg / m 2 / h, speed 2rpm, scraping film thickness 0.8mm, heat transfer oil temperature 200℃;

[0093] In the vacuum scraper drying device, the solution system obtained above was evaporated, and the evaporation was carried out under the conditions of a vacuum degree of -0.08MPa and a temperature of 190°C.

[0094] The yield of pentamethylenediamine is 98.9%.

Embodiment 3

[0096] Take the 1,5-pentamethylenediamine salinase conversion solution of the bacteria, and determine that the mass percent concentration of pentamethylenediamine is 20%. Evaporate on a pressure-0.095MPa rotary evaporator, control the temperature of the water bath at 90°C, concentrate until the mass percentage concentration of 1,5-pentamethylenediamine salt is 15%, add calcium hydroxide, calcium hydroxide 1.05:1, at 25°C Stir at high temperature for 1.5h; then feed into the vacuum scraper drying device of the present invention, feed rate 15kg / m 2 / h, speed 1rpm, scraping film thickness 0.6mm, heat transfer oil temperature 180℃;

[0097] In a vacuum scraper drying device, the above-mentioned solution system was evaporated, and the evaporation was carried out under the conditions of a vacuum degree of -0.08MPa and a temperature of 170°C.

[0098] The yield of pentamethylenediamine is 97.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com