Heating substrate for thermal print head and manufacturing method of heating substrate

A technology of thermal print head and printing direction, which is applied in printing and other directions, can solve the problems that the oleophobic property of the film layer is not mentioned, and the method of preparing the wear-resistant hydrophobic film layer is not mentioned, so as to improve carbon deposition and paper sticking phenomenon, strong hydrophobic and oleophobic ability, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

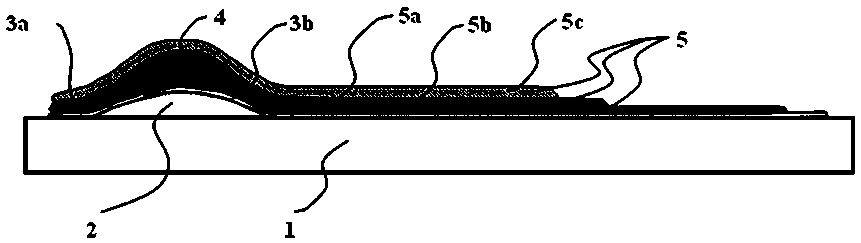

[0026] Such as figure 1 As shown, the heat-generating substrate for a thermal print head involved in the present invention includes an insulating substrate 1, and an underglaze layer 2 is provided on the entire or part of the surface of the insulating substrate 1. On the insulating substrate 1 and the underglaze layer 2 The surface of the common electrode 3a and individual electrodes 3b are provided, and the heating resistor 4 is arranged between the common electrode 3a and the individual electrodes 3b along the main printing direction, as a heating element for generating Joule heat, and one end of the common electrode 3a is along the secondary printing direction. One end of the individual electrode 3b is connected to the heating resistor 4 along the sub-printing direction, and the other end is connected to the control IC; The surfaces of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com