Patents

Literature

33results about How to "Improve carbon deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

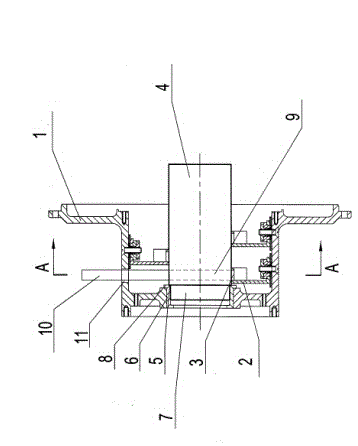

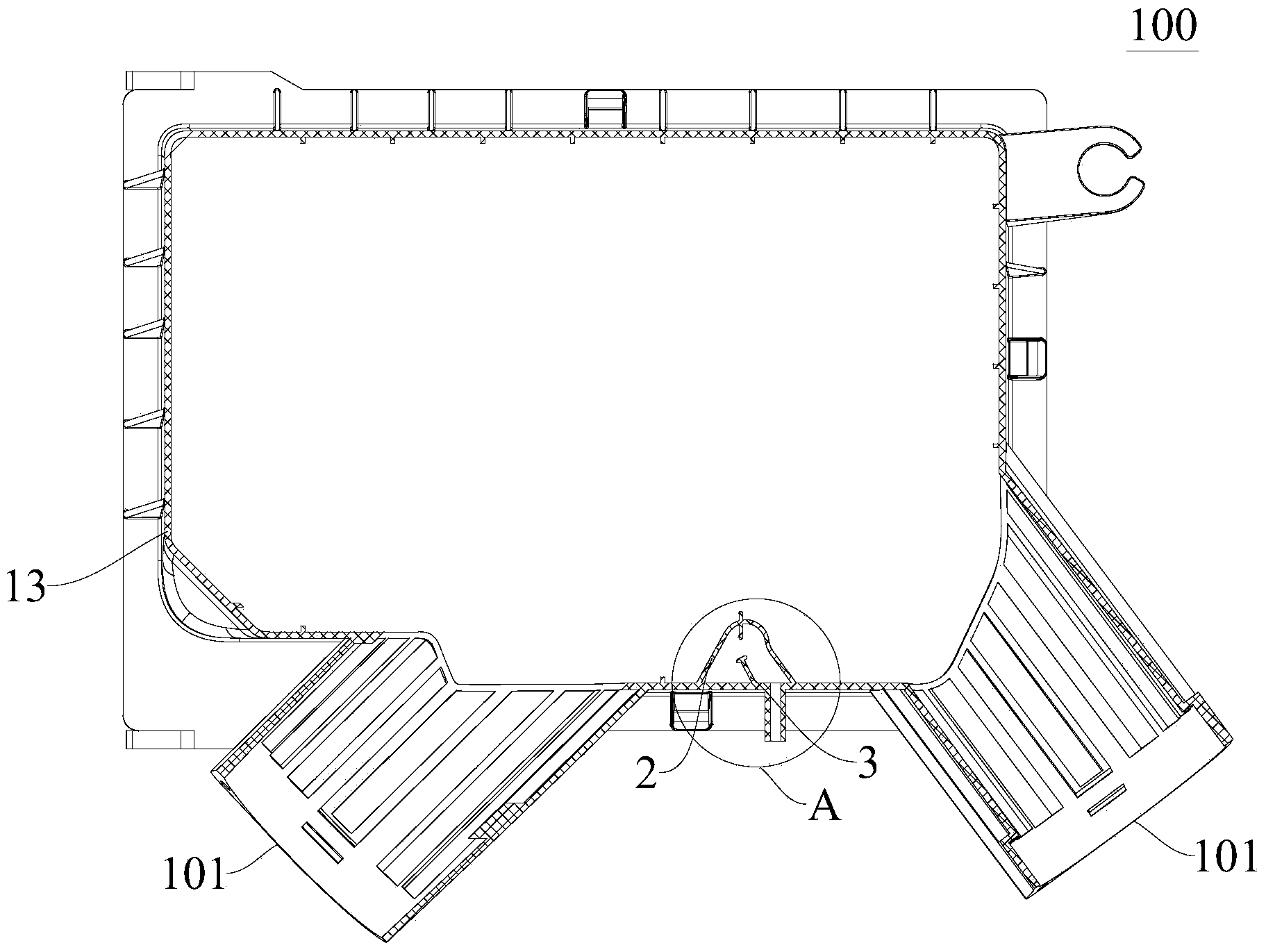

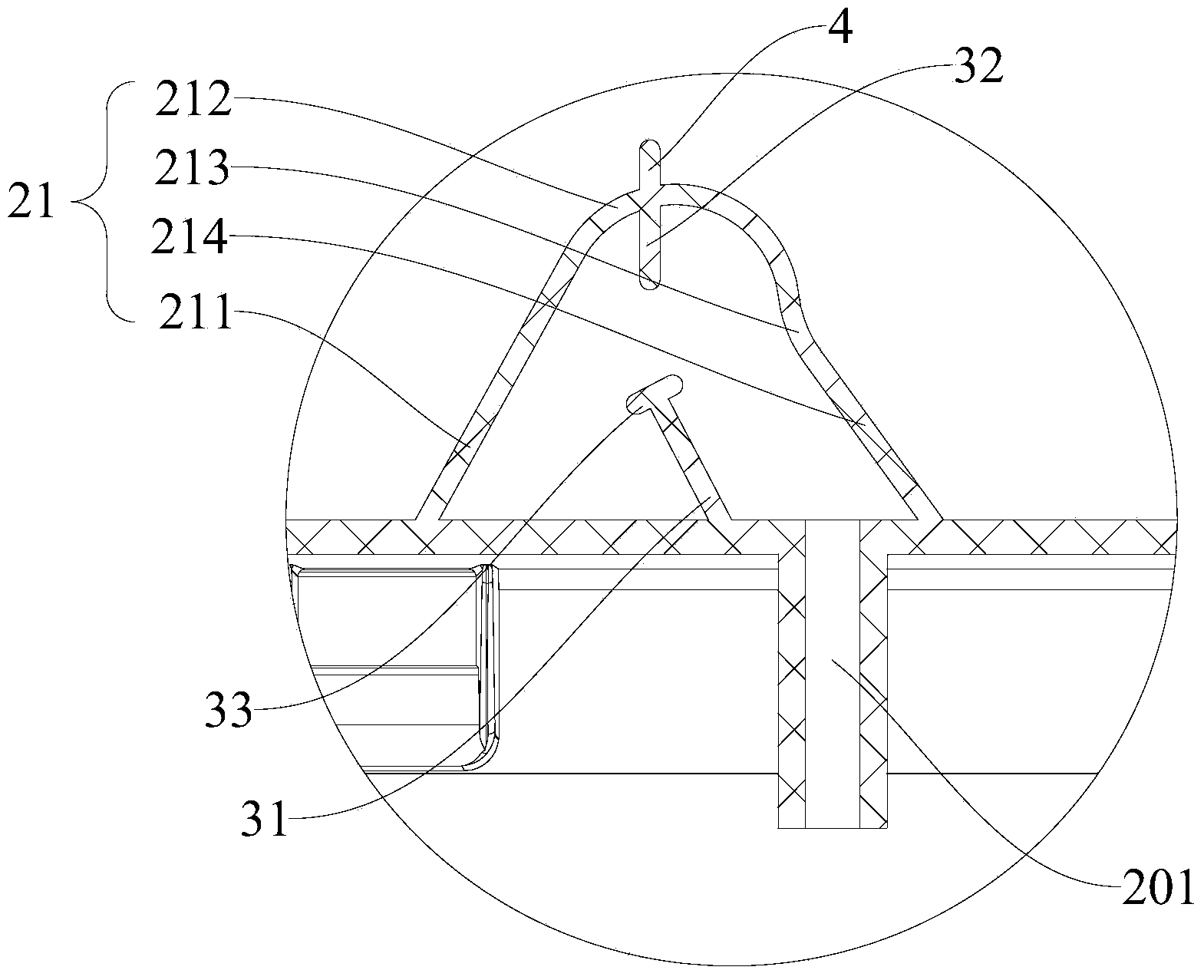

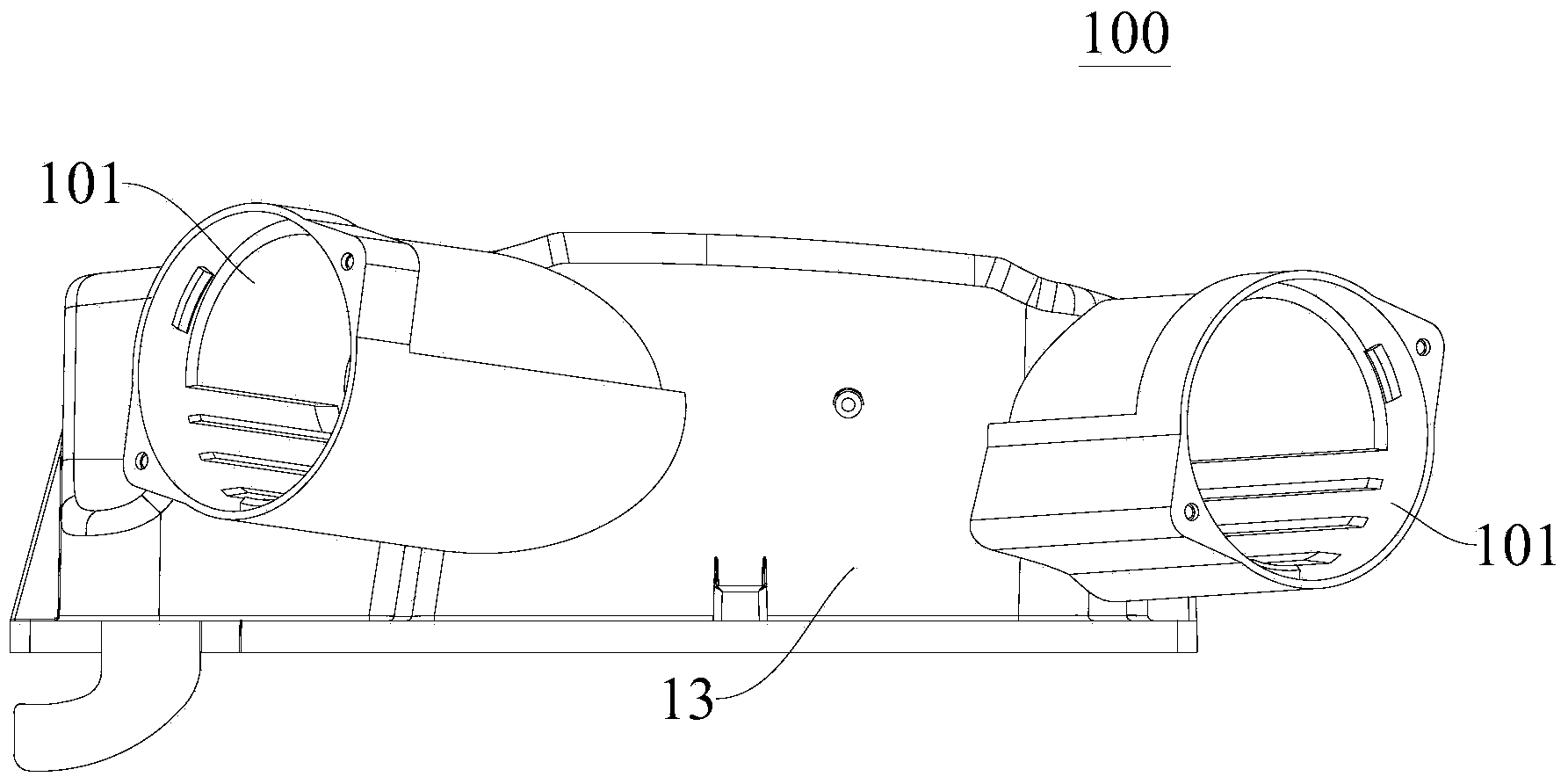

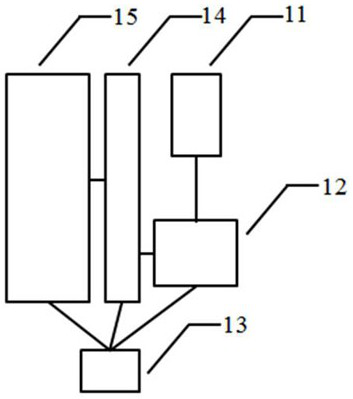

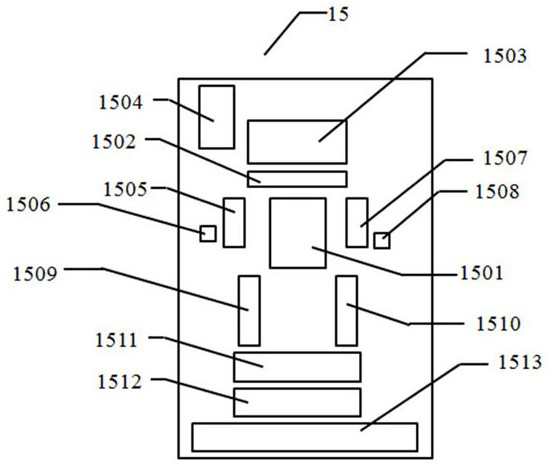

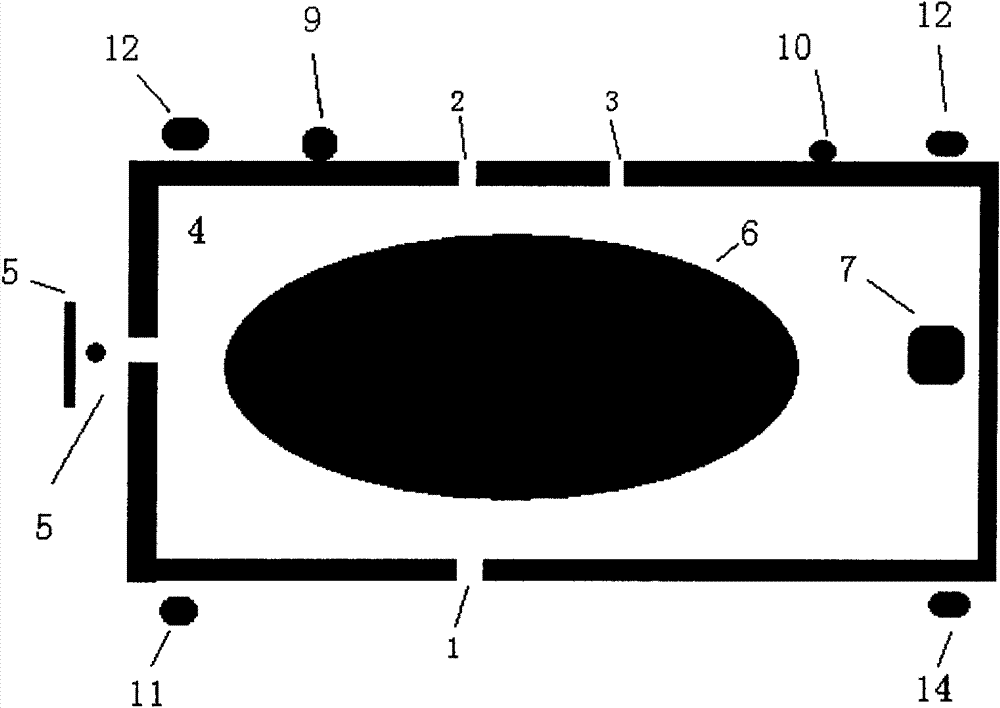

Assembly fixture for motor brush carrier

ActiveCN104539085AImprove assembly accuracyGuaranteed coincidenceManufacturing dynamo-electric machinesSupports/enclosures/casingsEngineeringMechanical engineering

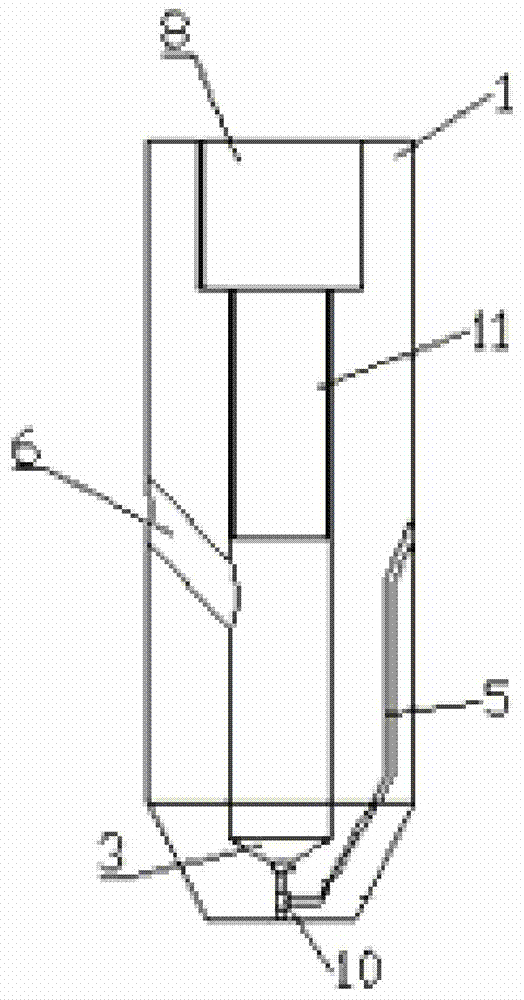

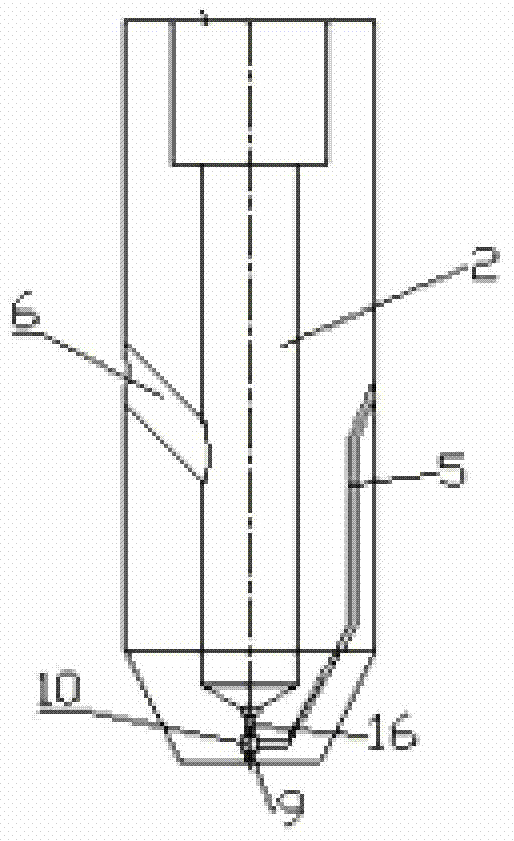

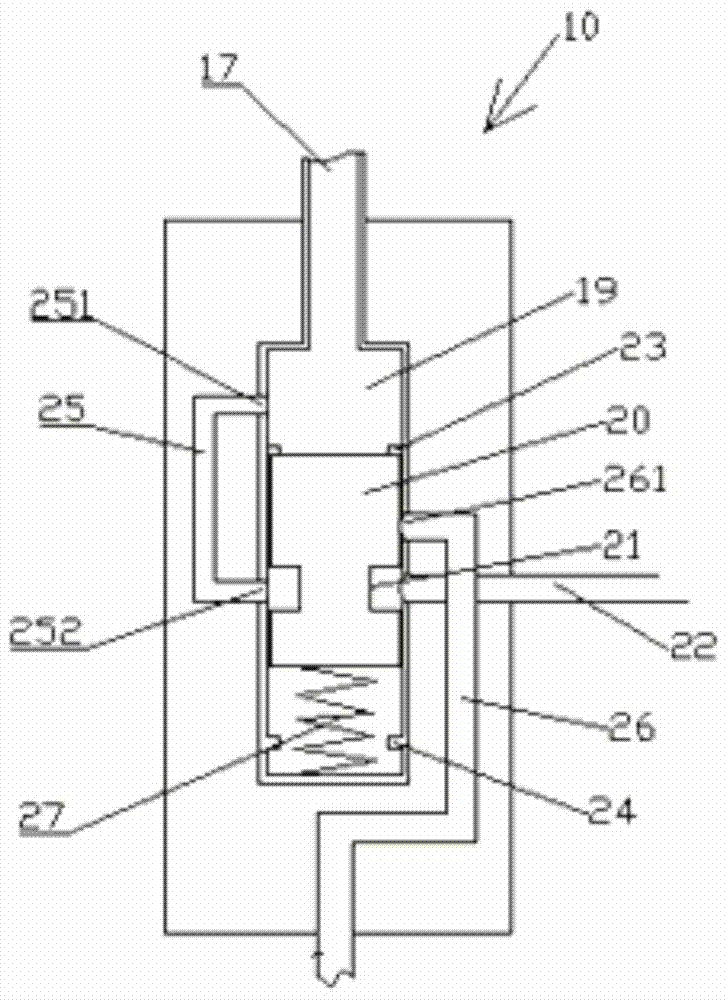

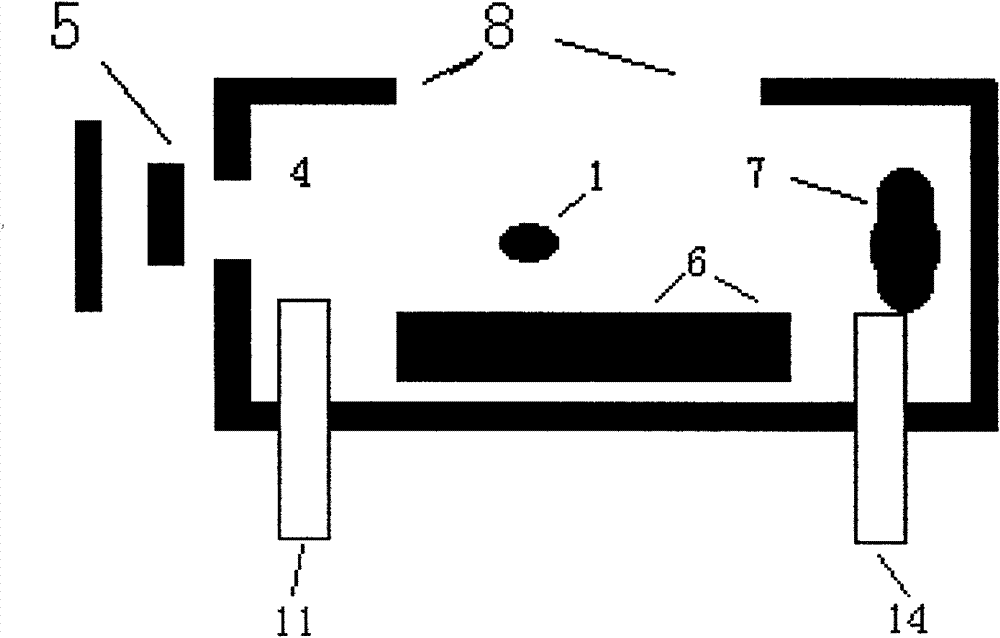

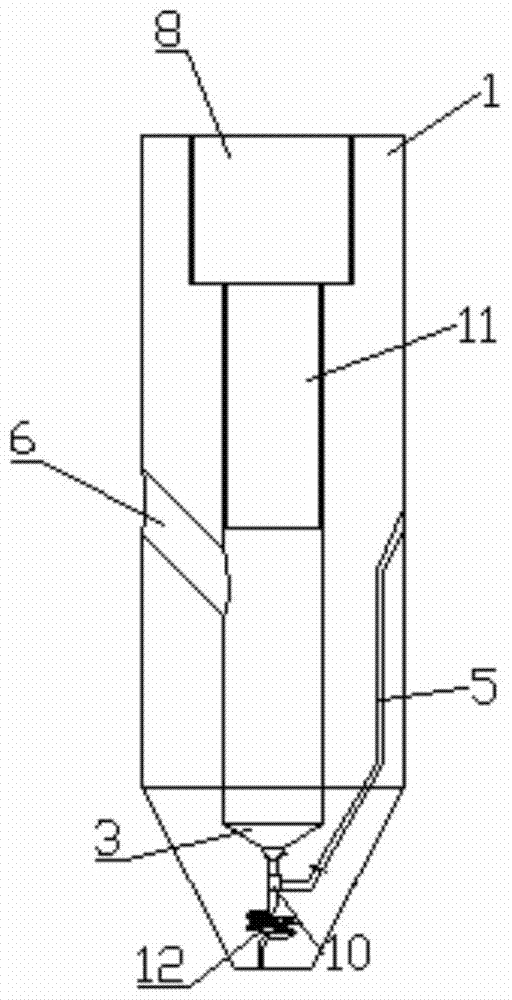

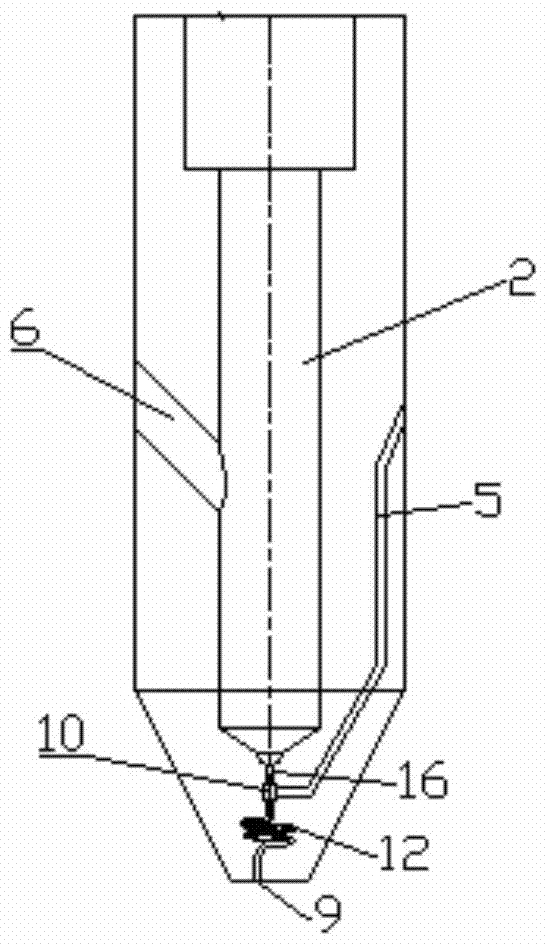

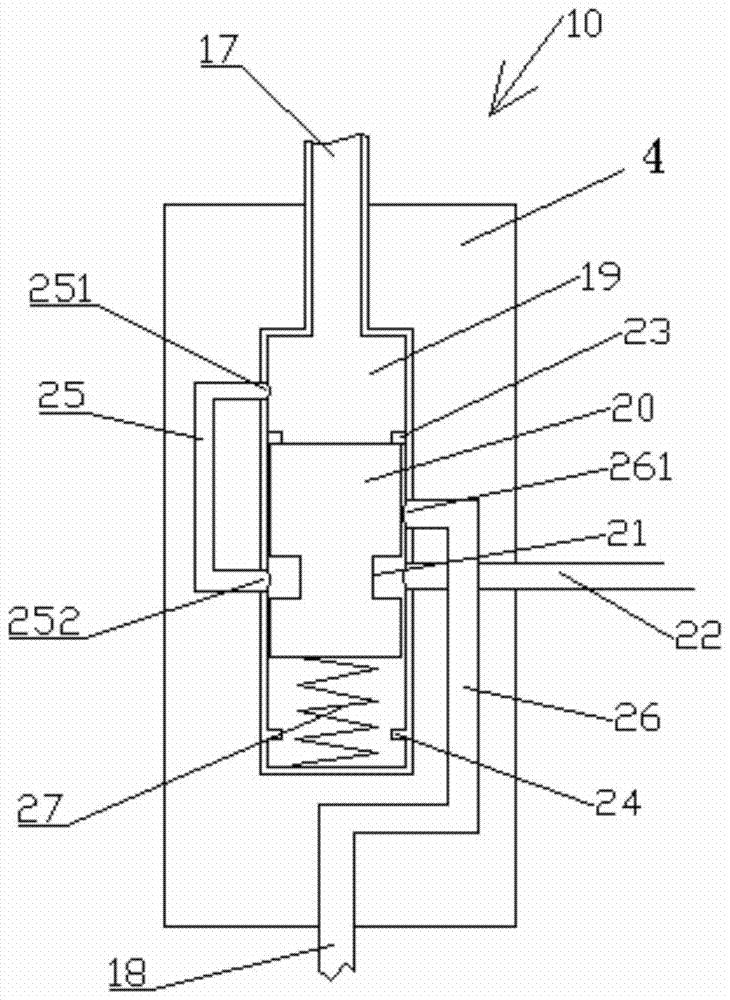

The invention discloses an assembly fixture for a motor brush carrier. The assembly fixture for the motor brush carrier achieves the technical effects of fine assembly and accurate locating of the brush carrier for fixing an electric brush in a motor. The assembly fixture comprises a motor end cover (1) and the electric brush carrier (2). The motor end cover (1) is provided with a receding hole (11) and an end cover bearing chamber (6). The electric brush carrier (2) is provided with an electric brush assembly hole (3). One end of an electric brush locating core shaft (4) is provided with a cylindrical step end shaft (7). The electric brush locating core shaft (4) is provided with a through hole (9). The cylindrical step end shaft (7) is arranged in the end cover bearing chamber (6). An inner check mouth end face (8) on the end cover bearing chamber (6) abuts against a cylindrical step vertical surface (5). An electric brush locating rod (10) penetrates through the receding hole (11) and the through hole (9) in sequence and then is connected with the electric brush assembly hole (3) in a penetrating mode. The assembly fixture substantially improves the assembly accuracy of the electric brush and a rotor and lowers the occurrence rate of collecting ring ablation accidents.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

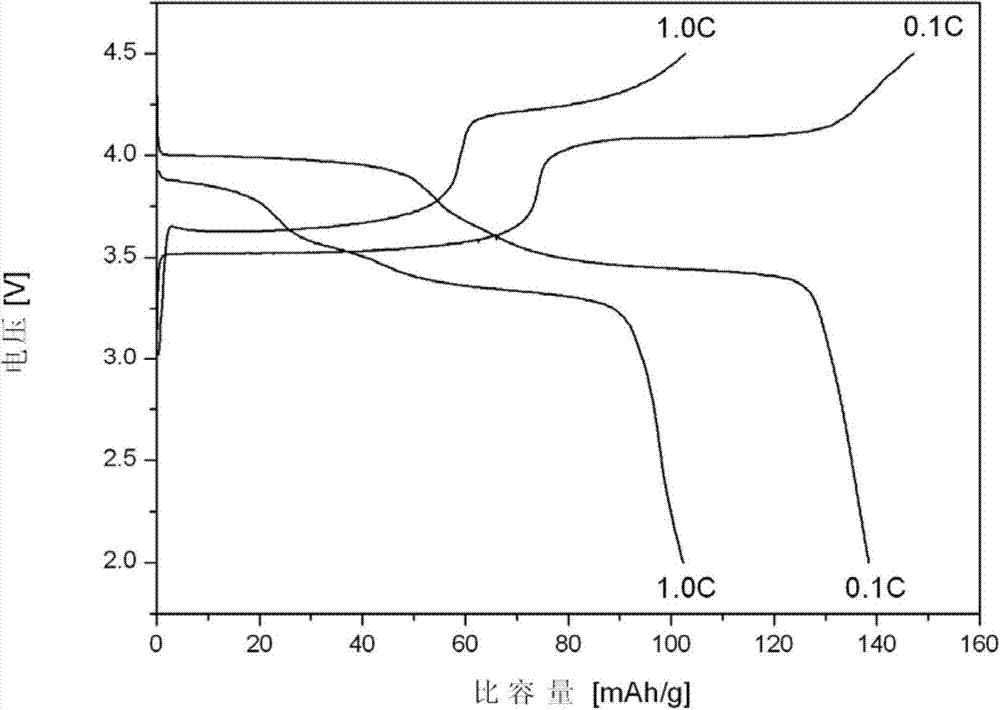

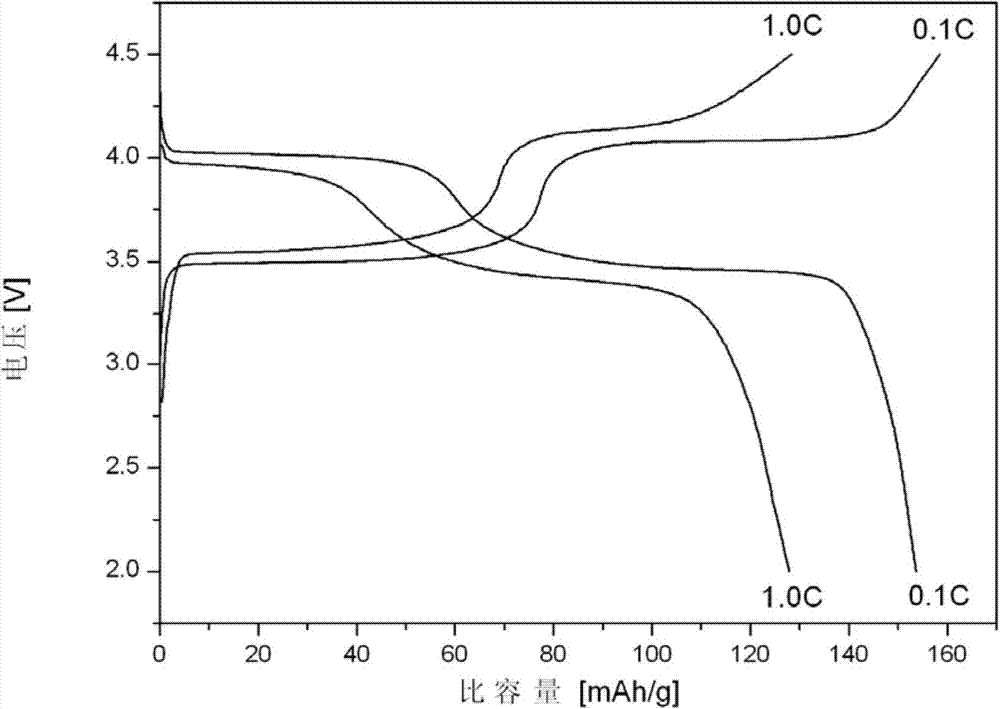

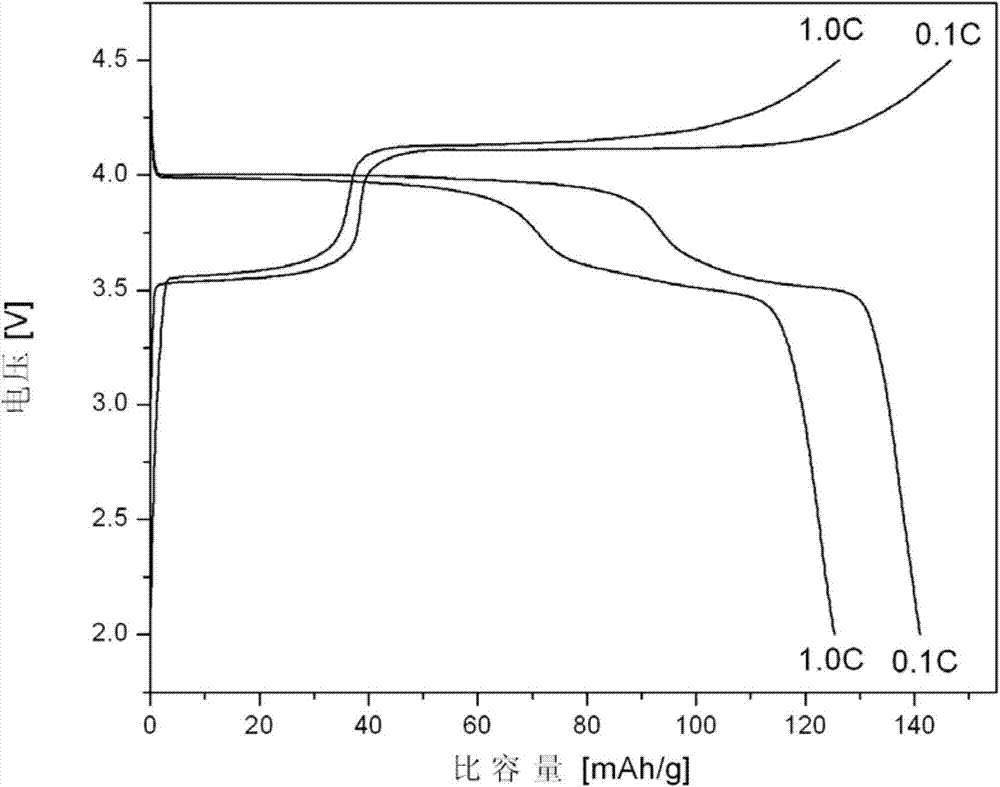

Precursor rich in iron on surface and rich in manganese on core and method for preparing carbon-coated manganese-iron-lithium phosphate material by taking precursor as raw material

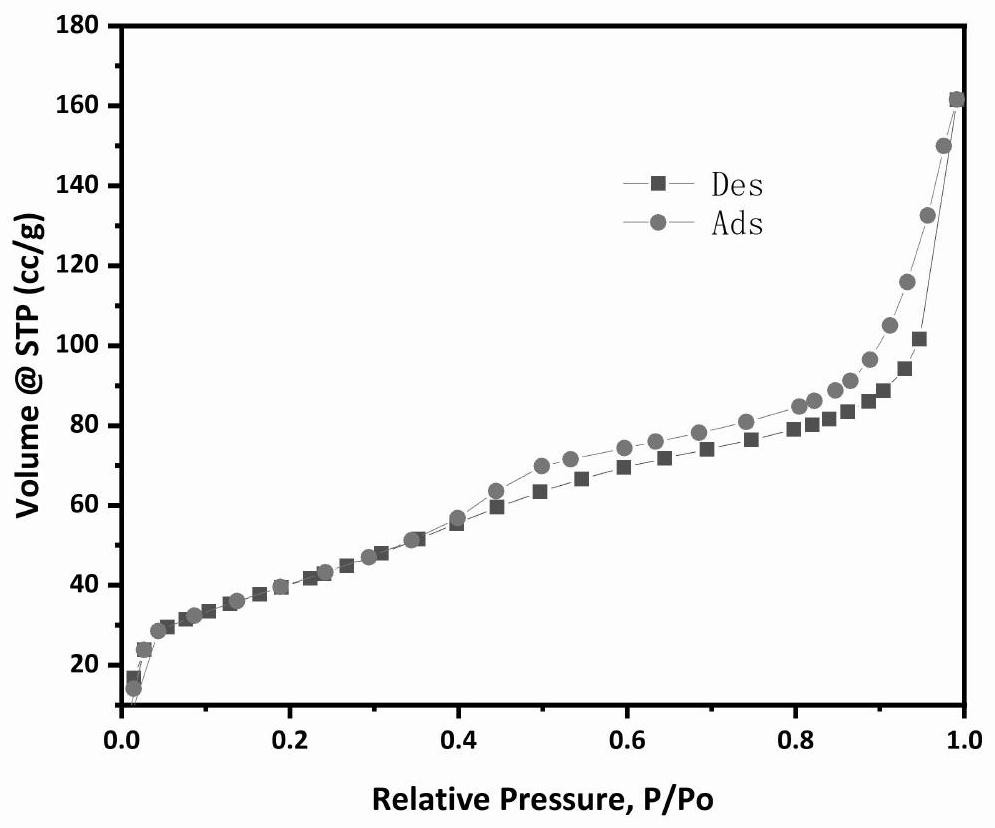

ActiveCN104852037AImprove carbon depositionImproved conductivity and electrochemical performanceCell electrodesCarbon sourceCarbon coated

The invention discloses a precursor rich in iron on the surface and rich in manganese on the core and a method for preparing a carbon-coated manganese-iron-lithium phosphate material by taking the precursor as a raw material. The primary particle size of the precursor is 15-500 nanometers; the specific surface area is 5-100 m<2> / g; iron elements are enriched 0-5 nanometers away from particle surfaces; the content of manganese within a depth range is less than 0.01 wt%; and manganese elements are intensively distributed on the cores of material particles. The method for preparing the carbon-coated manganese-iron-lithium phosphate material based on the precursor comprises the following steps: synthesizing the precursor according to the chemical formula of manganese-iron-lithium phosphate, putting the precursor, a Li-containing compound, a P-containing compound, a metal M-containing compound and a carbon source organic matter raw material into a dispersion medium, and mixing the materials to obtain a slurry; and drying and calcining the slurry to obtain the carbon-coated manganese-iron-lithium phosphate material. The precursor which is rich in iron on the surface is taken as the raw material for synthesizing the manganese-iron-lithium phosphate material, and the carbon deposition state on the surfaces of electrode material particles in a calcining process is improved, so that the electrical conductivity and electrochemical performance are improved.

Owner:中国有研科技集团有限公司

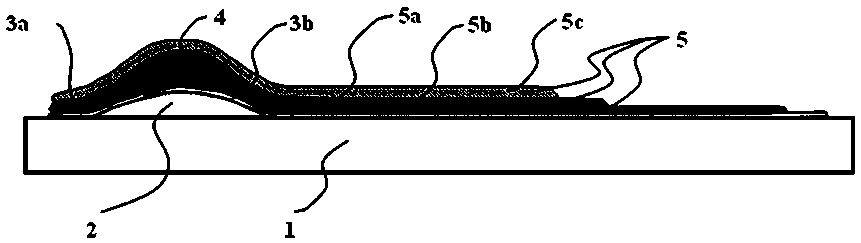

Heating substrate for thermal print head and manufacturing method of heating substrate

PendingCN109693451AExtended service lifeStrong hydrophobicity and oleophobicityPrintingInorganic materialsTransition layer

The invention provides a heating substrate for a thermal print head. The heating substrate comprises an insulating substrate, wherein a bottom glaze layer is arranged on the surface of the insulatingsubstrate in whole or in part, a common electrode and an individual electrode are arranged on the surface of the insulating substrate and the bottom glaze layer, a heating resistance body is configured between the two electrodes in the main printing direction, the heating resistance body is connected to one end of the common electrode in the sub-printing direction, and a printing power source is connected to the other end of the common electrode ; the heating resistance body is connected to one end of the individual electrode in the sub-printing direction, a control IC is connected to the other end of the individual electrode; the surfaces of the heating resistance body, the common electrode and a part of the individual electrodes are covered with an insulating protective layer, a transition layer is arranged on the protective layer, and a hydrophobic and oleophobic functional layer is arranged on the transition layer, and the functional layer is made of an inorganic material, the protective layer, the transition layer and the functional layer form a surface composite layer. The heating substrate for the thermal print head has high hydrophobic and oleophobic ability, the phenomenonof carbon deposition and paper sticking in the printing process can be improved, and the service life of the thermal print head can be prolonged.

Owner:SHANDONG HUALING ELECTRONICS

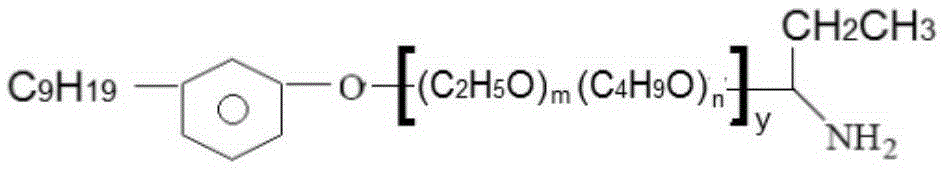

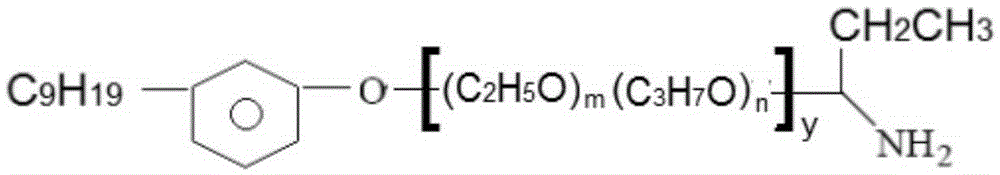

Fuel oil additive, preparation method and application method thereof

InactiveCN106635204AImprove carbon depositionLiquid carbonaceous fuelsFuel additivesCombustion chamberGasoline

The invention relates to a fuel oil additive. The fuel oil additive comprises the following components by gross weight according to 100 wt%: 70wt% to 90wt% of nonyl phenol polyether amine, 10wt% to 30wt% of polyisobutylene amine, and 0 to 20wt% of an auxiliary additive. The fuel oil additive disclosed by the invention is good in capability of removing accumulated carbon in a gas charging valve of a gasoline engine and a combustion chamber.

Owner:3M INNOVATIVE PROPERTIES CO

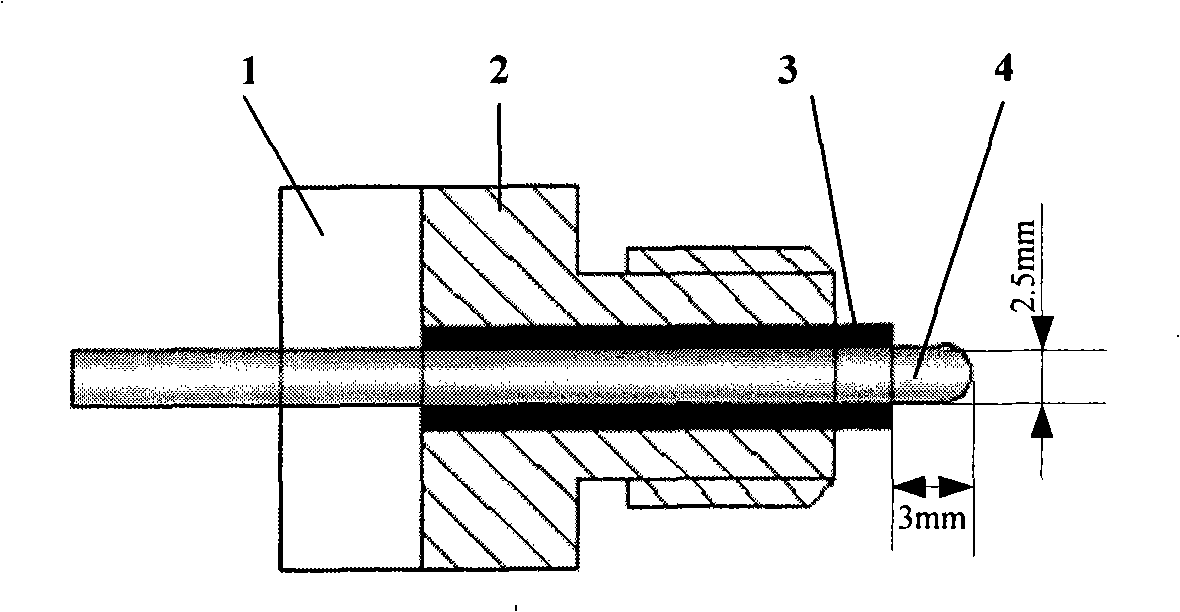

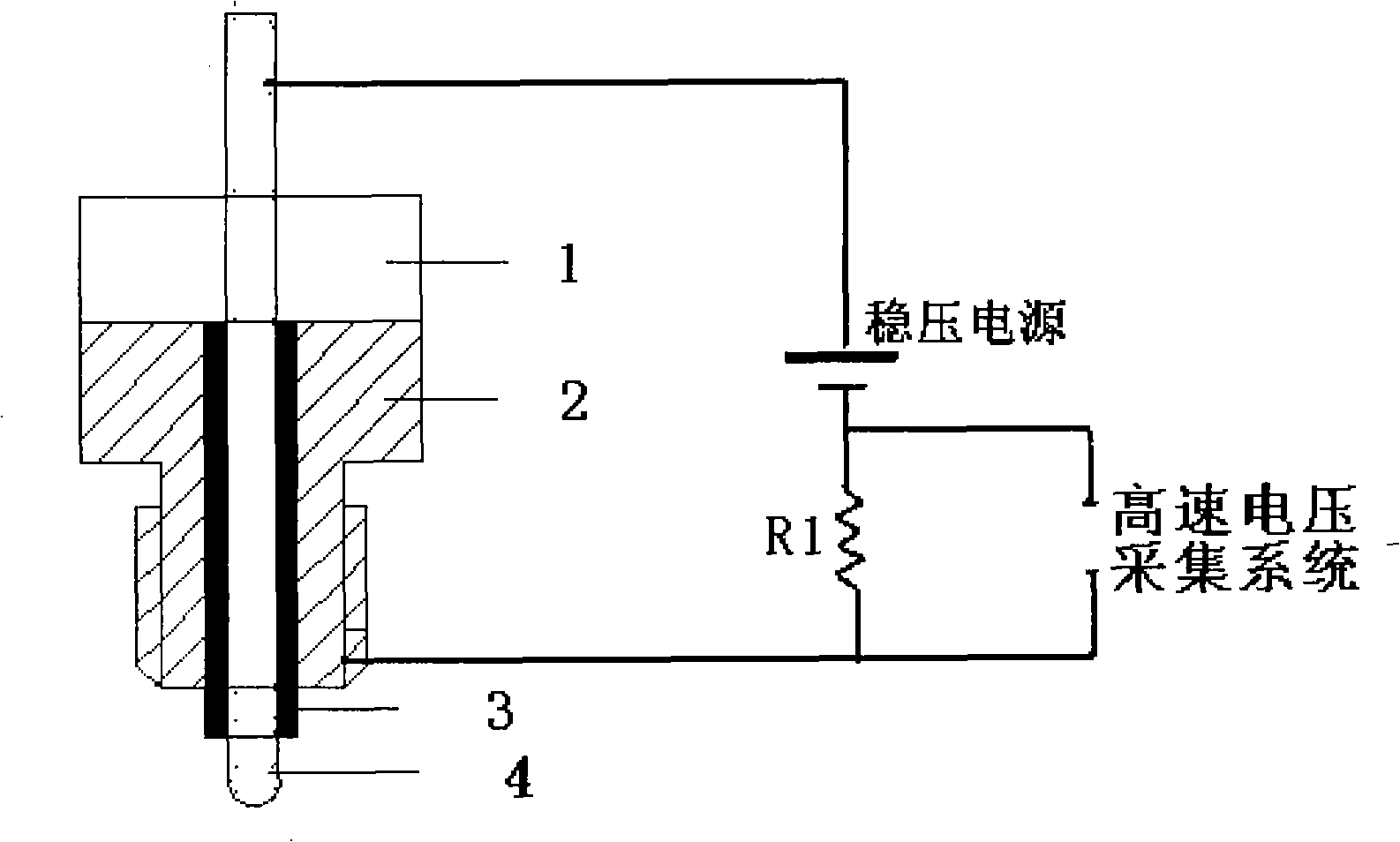

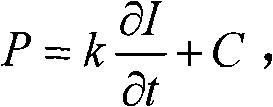

High temperature pressure measurement method and sensor for impulse knocking engine based on ion current

InactiveCN101319953ASimple structureLow costEngine testingRapid change measurementEngineeringTemperature resistance

The invention relates to a high temperature pressure measuring method and a sensor for a pulse detonation engine based on ion current. The method includes as follows: when a detonation engine burns, a plurality of free electrons and ions exist in an induction area in the detonation waves; an ion probe is adopted and a stable bias voltage is applied at the poles of the probe to form a continuous ion current in a measuring current; the attenuation speed of the current has linear relation with the pressure in a detonation tube; the pressure in the detonation tube is obtained according to the attenuation speed of the ion current. The sensor has characteristics in the structure that the anode of the sensor is inserted into a high temperature ceramics insulating tube and then is inserted into a screw cap together with the high temperature ceramics insulating tube. The screw cap is arranged in the tube wall of the detonation engine; a silicon gel seal layer is arranged above the screw cap; a stable power is directly applied between the anode and the screw cap. The device has the advantage of high temperature resistance, impact resistance, simple structure, convenient mounting and maintaining and low cost; besides, the device is applicable for the pressure measuring of the pulse detonation engine under the high temperature environment.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

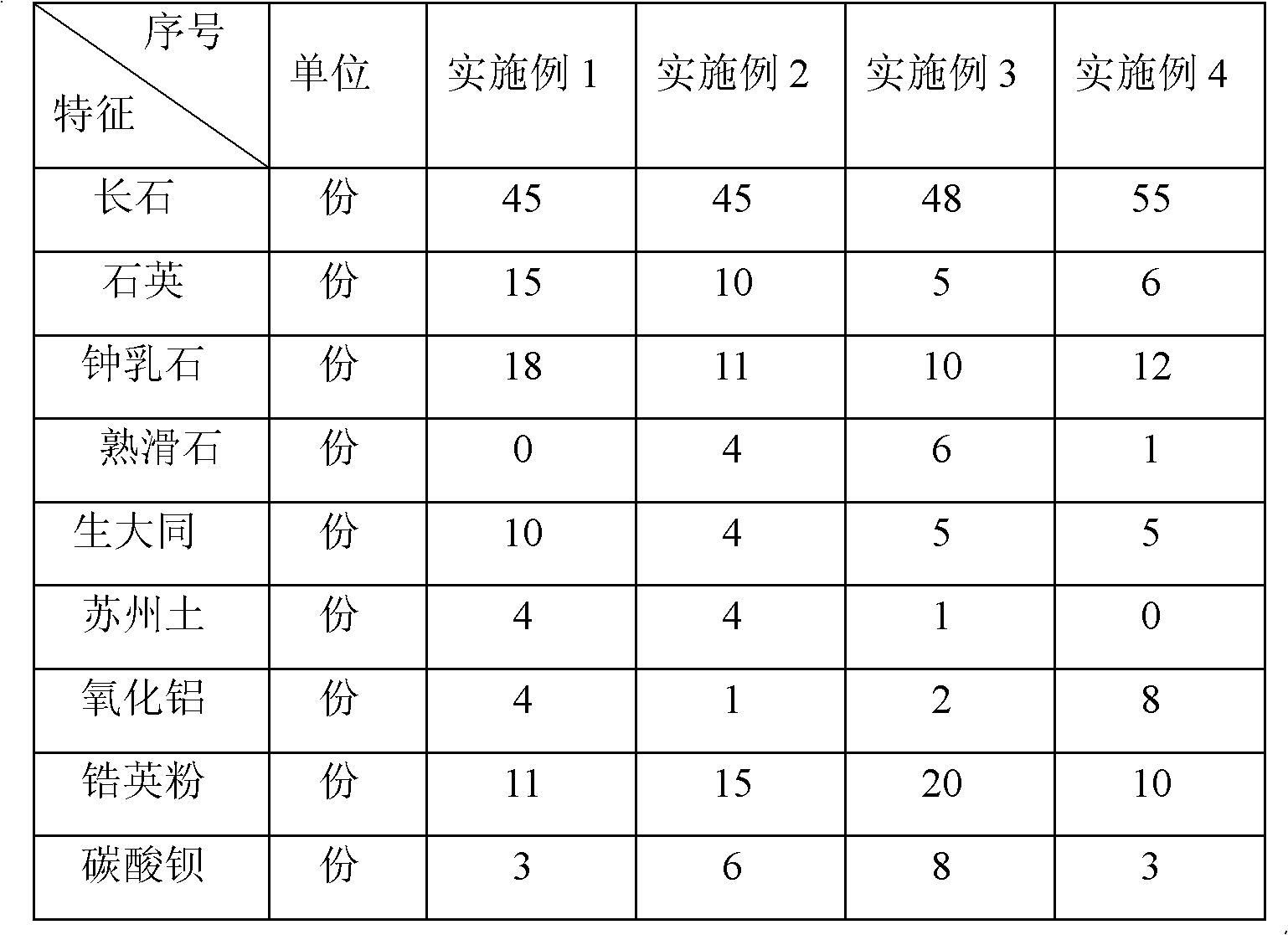

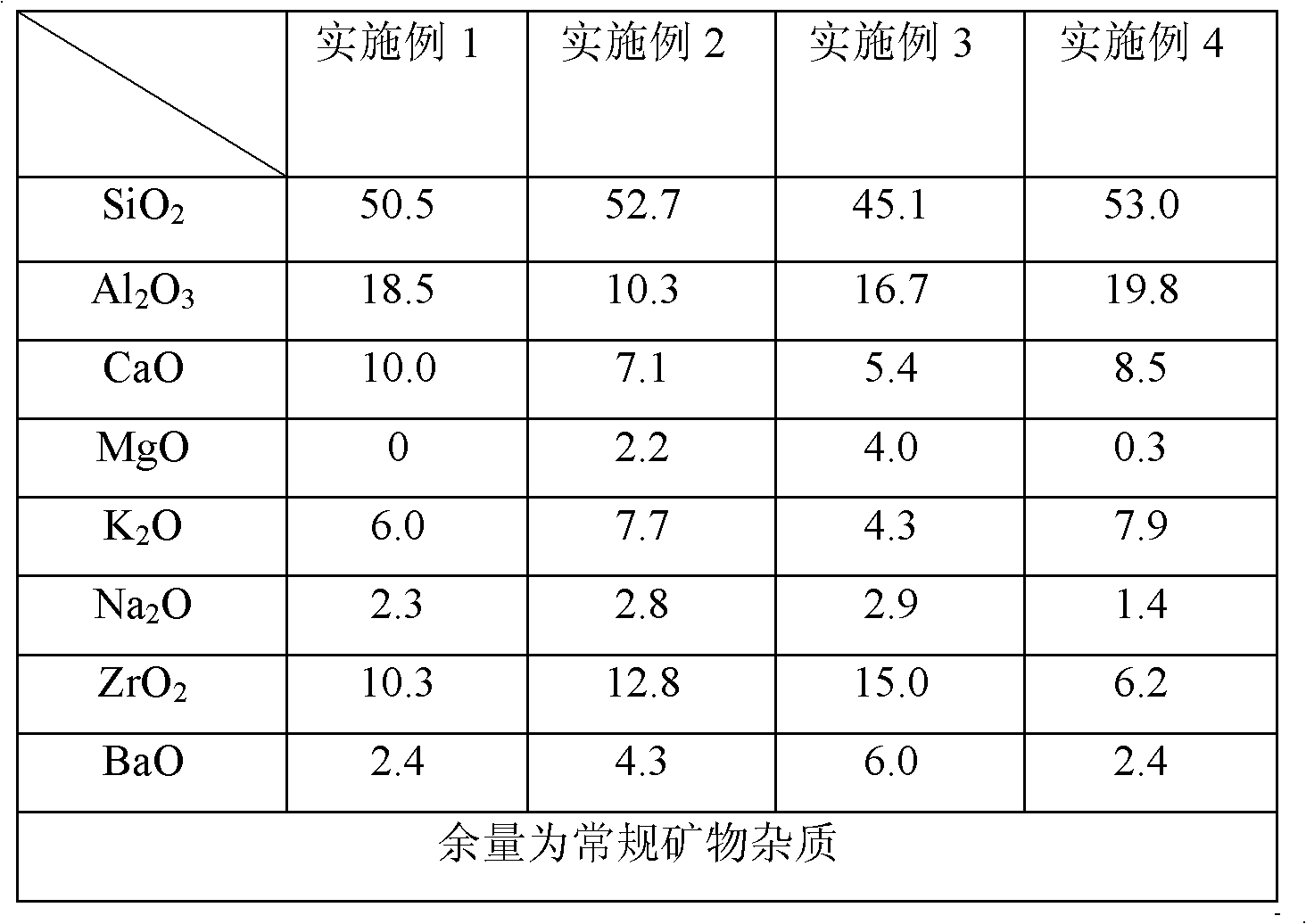

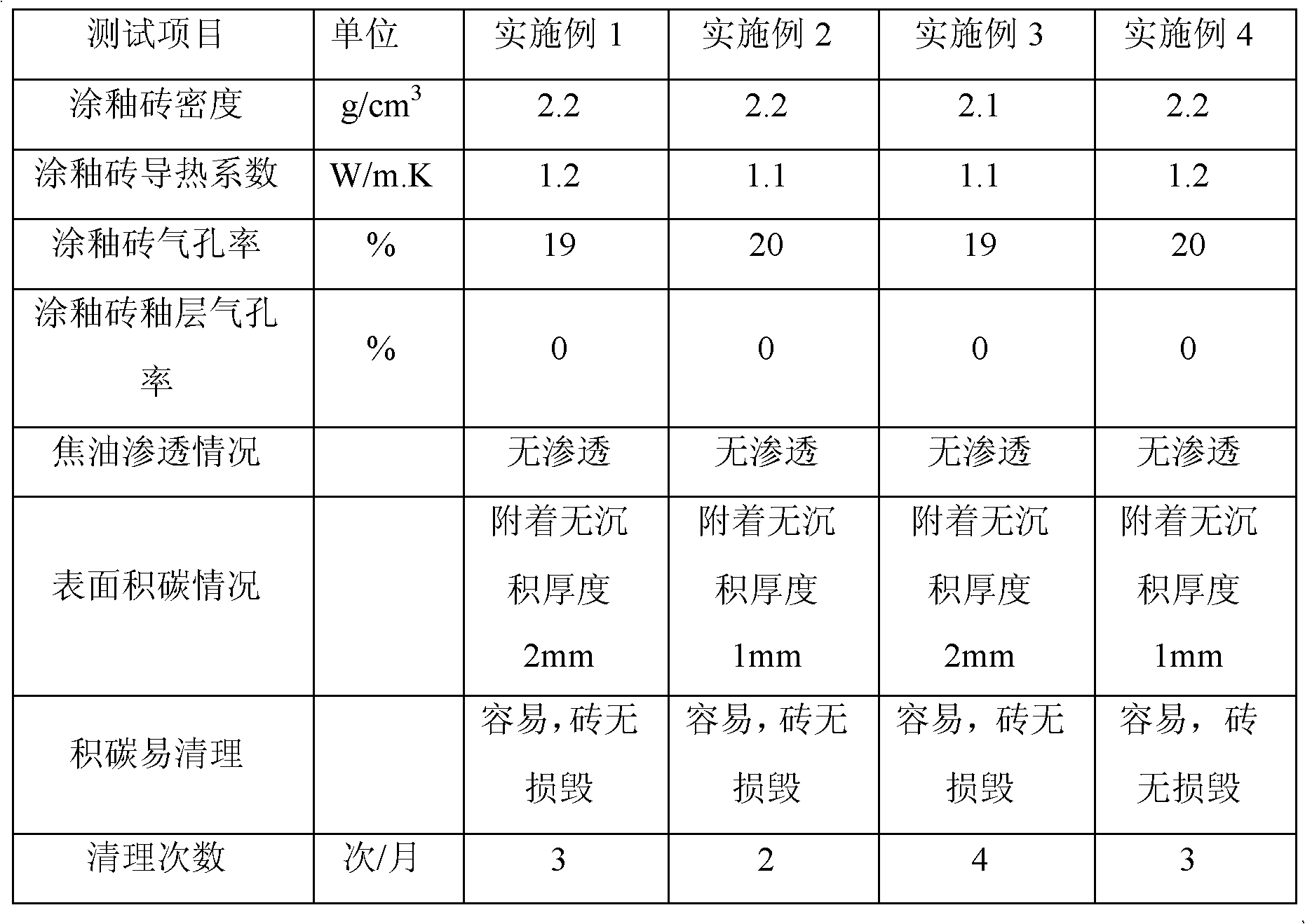

Enameled brick for oven door of coke oven

InactiveCN102617189AMeet the use requirementsIncrease softening temperature Melting temperatureStalactiteBrick

The invention relates to an enameled brick for an oven door of a coke oven and belongs to the technical field of fireproofing material preparation. The enameled brick consists of a brick body and a glaze material coated on the surface of the brick body. The enameled brick is characterized in that the glaze material is prepared from the following ingredients in parts by weight: 45 to 55 parts of feldspar, 5 to 15 parts of quartz, 10 to 18 parts of stalactite, 0 to 6 parts of ripe talc, 4 to 10 parts of raw datong, 0 to 4 parts of Suzhou soil, 1 to 8 parts of alumina, 10 to 20 parts of zircon powder and 3 to 8 parts of barium carbonate. The oven door of the coke oven built by the enameled brick for the oven door of the coke oven provided by the invention has the advantages that the low freecarbon granule and tar penetration adhesion phenomenon can be reduced, the surface carbon deposition condition of the oven door is obviously improved in the use process, the average month adhesion deposition-free thickness is 1 to 2mm, the monthly average cleaning times are 2 to 4, the cleaning times and the cleaning difficulty of the carbon deposition of the oven door of the coke oven are effectively reduced, and the mechanical damage to the oven door of the coke oven in the cleaning process is reduced. Through the monitoring on the enameled brick used for one year, the brick body of the enameled brick for the oven door of the coke oven does not have the damage phenomenon, and the brick body surface of the brick for the oven door of the coke oven does not have tar penetration conditions.

Owner:SHANDONG WANQIAO GROUP

Characteristic kiln change technology of Nixing ceramics

The invention discloses a characteristic kiln change technology of Nixing ceramics, comprising the steps of preparing a blank body, molding the blank body, trimming the blank body, drying the blank body and sintering the blank body. The step of sintering the blank body comprises the following steps: 1) putting the dried blank body in a kiln, heating the temperature up to 450-550 DEG C with a heating speed of 80-120 DEG C / h, then heating the temperature up to 1100-1200 DEG C with a heating speed of 130-180 DEG C / h, and continuously sintering for 0.5-1 h at the temperature of 1100-1200 DEG C; 2) putting materials for kiln change in the kiln from a kiln hole, wherein, the additional quantity of the materials for kiln change is 2-3 kg / m<3>, and the materials for kiln change comprises 1-4 weight portions of pine, 1-3 weight portions of raw leaves, 1-3 weight portions of wood chips, 2-5 weight portions of coal and 2-4 weight portions of turpentine; 3) continuously sintering for 0.5-1 h at the temperature of 1150-1200 DEG C; 4) gradually decreasing the temperature in the kiln; and 5) after cooling, taking out the sintered blank body.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

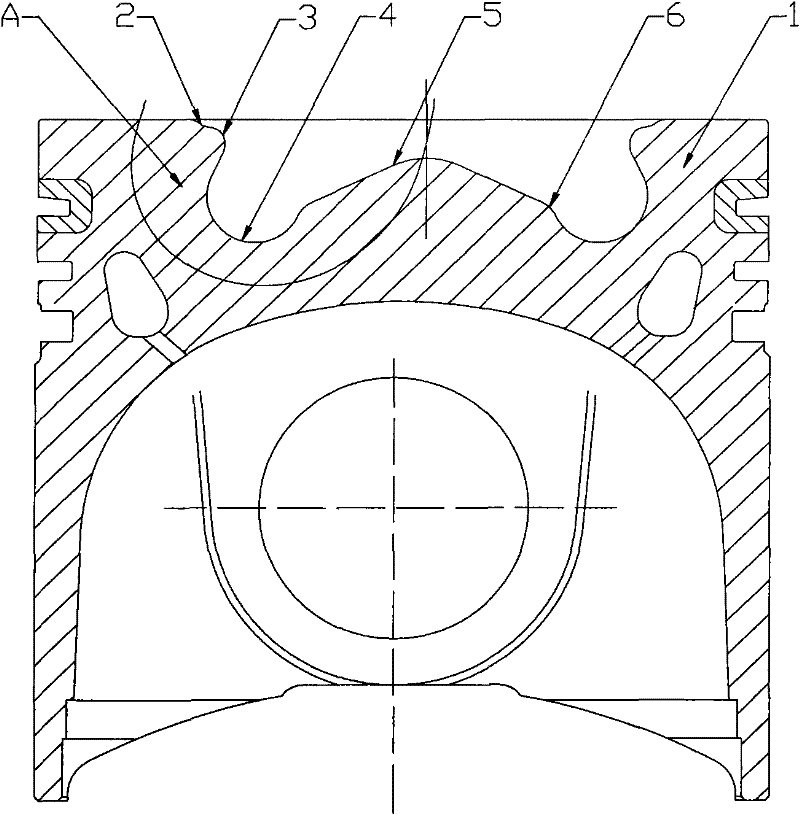

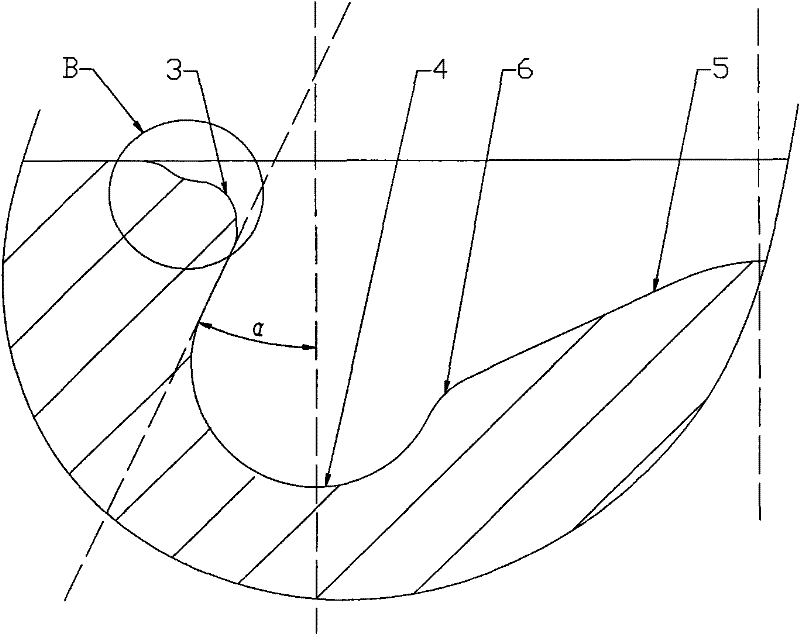

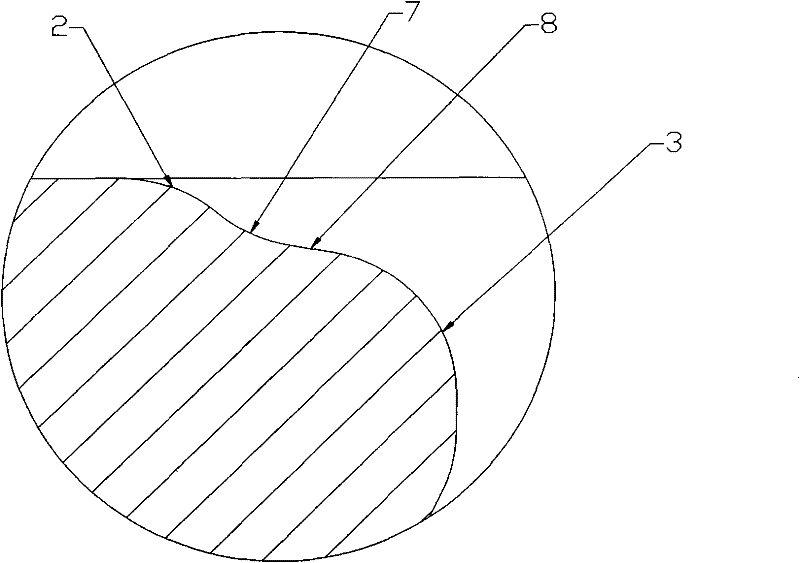

Combustion chamber of high-speed diesel engine

InactiveCN102678260APrevent hitting the wallWell mixedInternal combustion piston enginesCombustion chamberPulp and paper industry

The invention discloses a combustion chamber of a high-speed diesel engine. The combustion chamber is cylindrically arranged at the end part of a piston rod, and the combustion chamber is characterized in that the combustion chamber sequentially comprises an inward contraction port, a throat port, a bottom groove and a boss from the top end of the piston rod to the bottom of the combustion chamber, wherein the inward contraction port is of an annular arc-shaped groove with the inner diameter which is gradually reduced from the top end of the piston rod, the throat port is of an annular arc-shaped bulge connected to the bottom edge of the inward contraction port, the bottom groove is of an arc-shaped groove arranged on the edge at the bottom of the combustion chamber, the inner diameter of the throat port is smaller than those of the inward contraction port and the bottom groove, the boss is of a spherical crown-like structure arranged at the center of the bottom of the combustion chamber, a diversion table is arranged between the bottom edge of the boss and the lower edge of the bottom groove, and the diversion table is of an annular arc-shaped raised structure. The combustion chamber disclosed by the invention can be used for preventing a high-pressure injected oil beam from being subjected to a wall impingement phenomenon, improving the fuel oil spatial distribution and oil-gas mixing uniformity, and further ensuring that the engine is higher in thermal efficiency and lower uin oil consumption and emission.

Owner:GUANGXI YUCHAI MASCH CO LTD

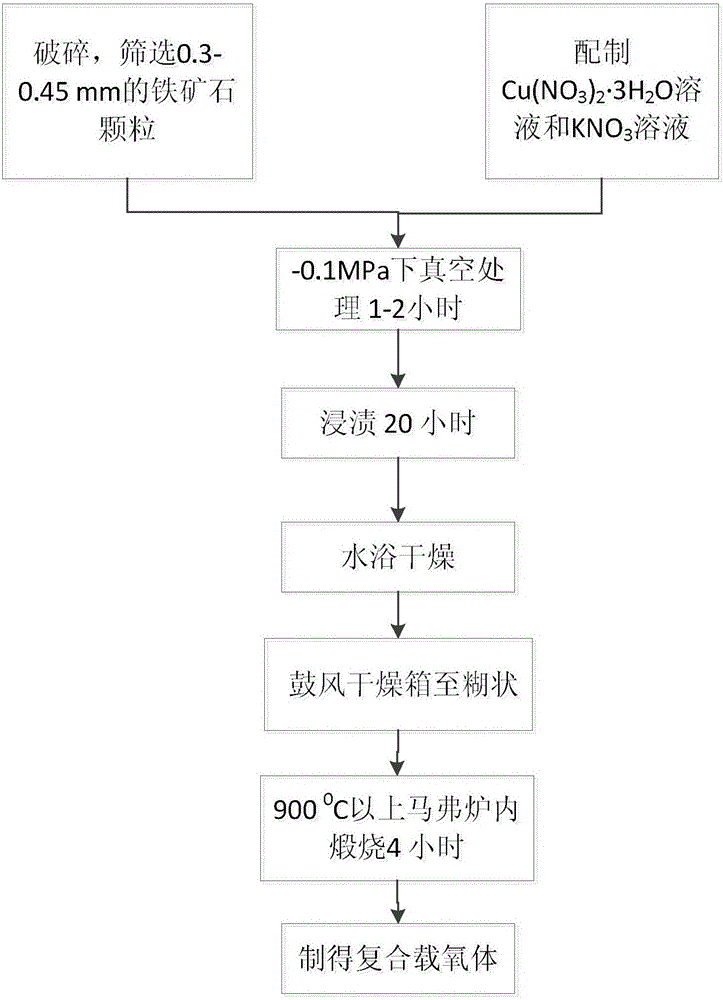

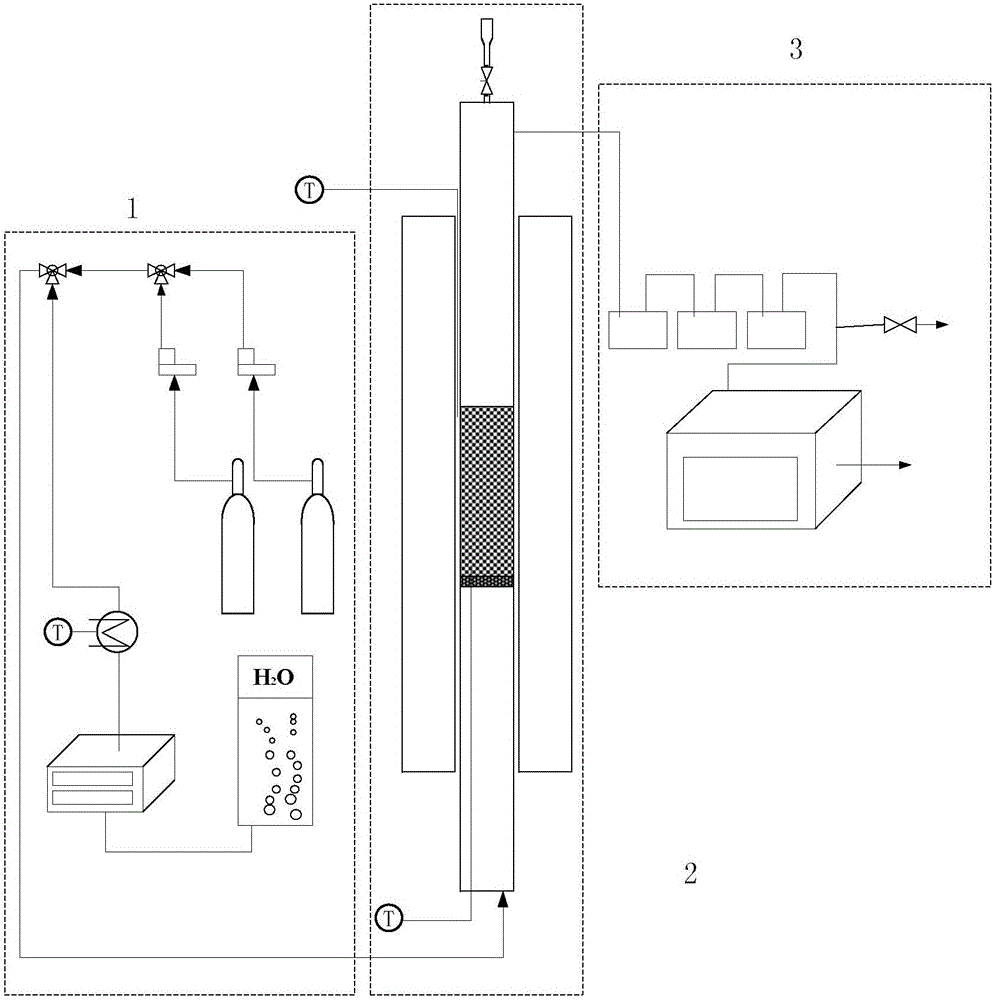

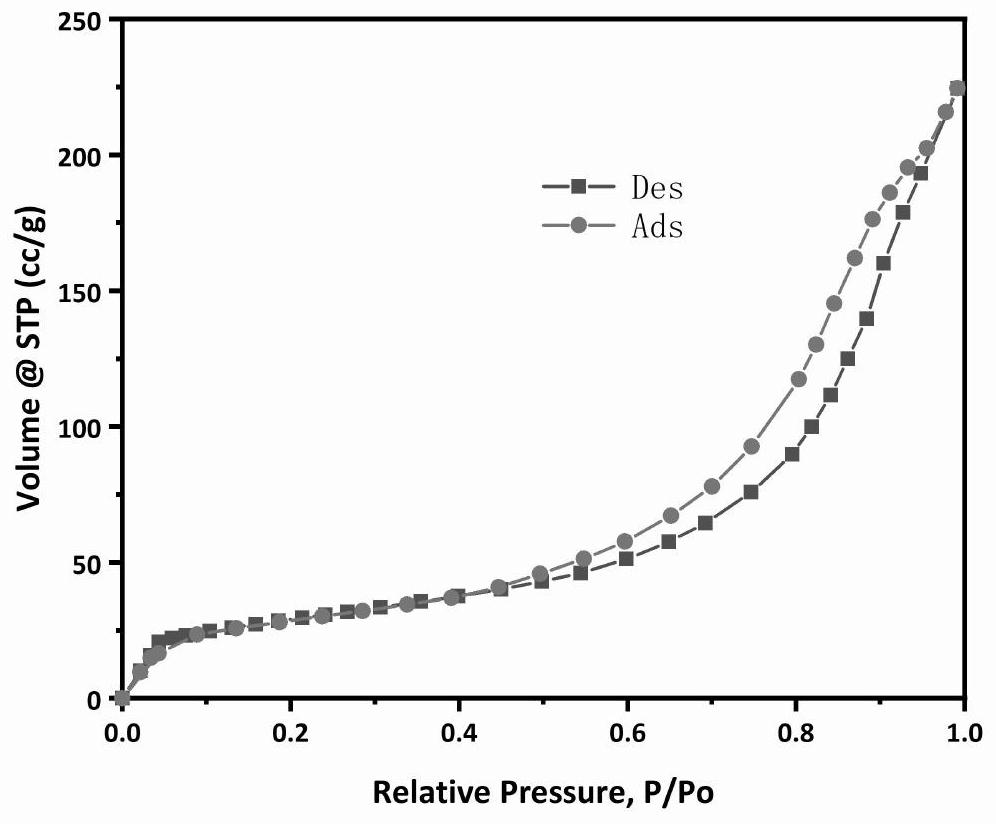

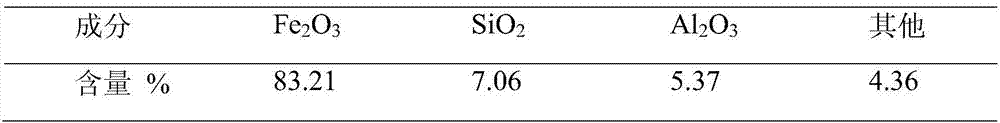

Chemical chain hydrogen production composite oxygen carrier with anti-carbon property and preparation method of chemical chain hydrogen production composite oxygen carrier

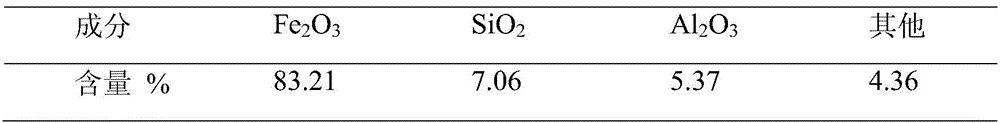

ActiveCN105754681ALow costGood market prospectPhysical/chemical process catalystsHydrogen productionMineralogyHydrogen production

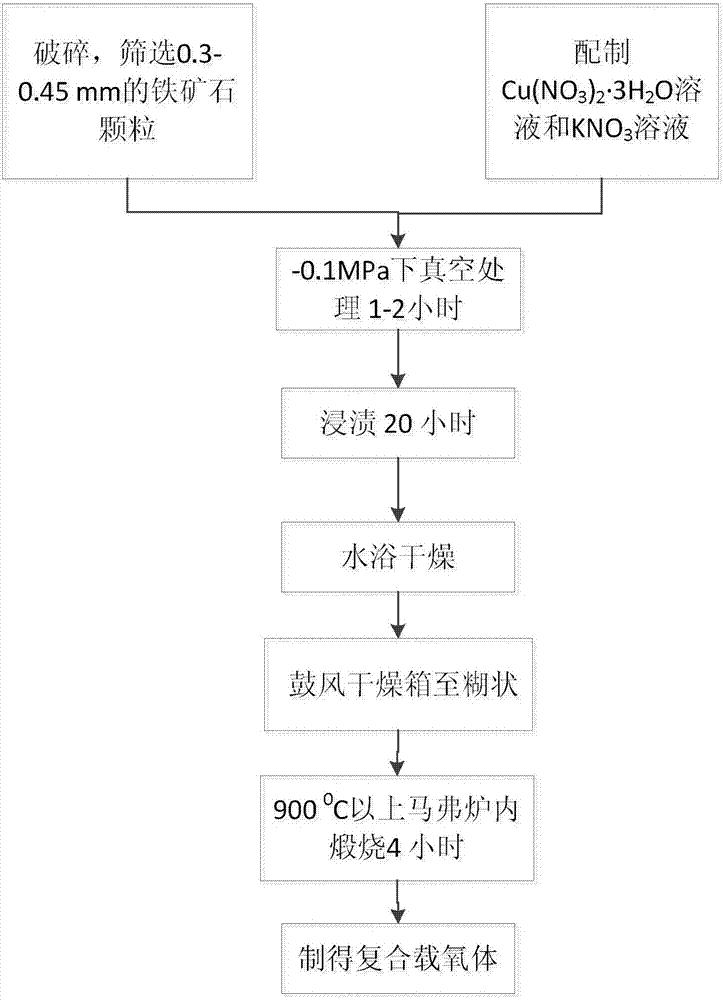

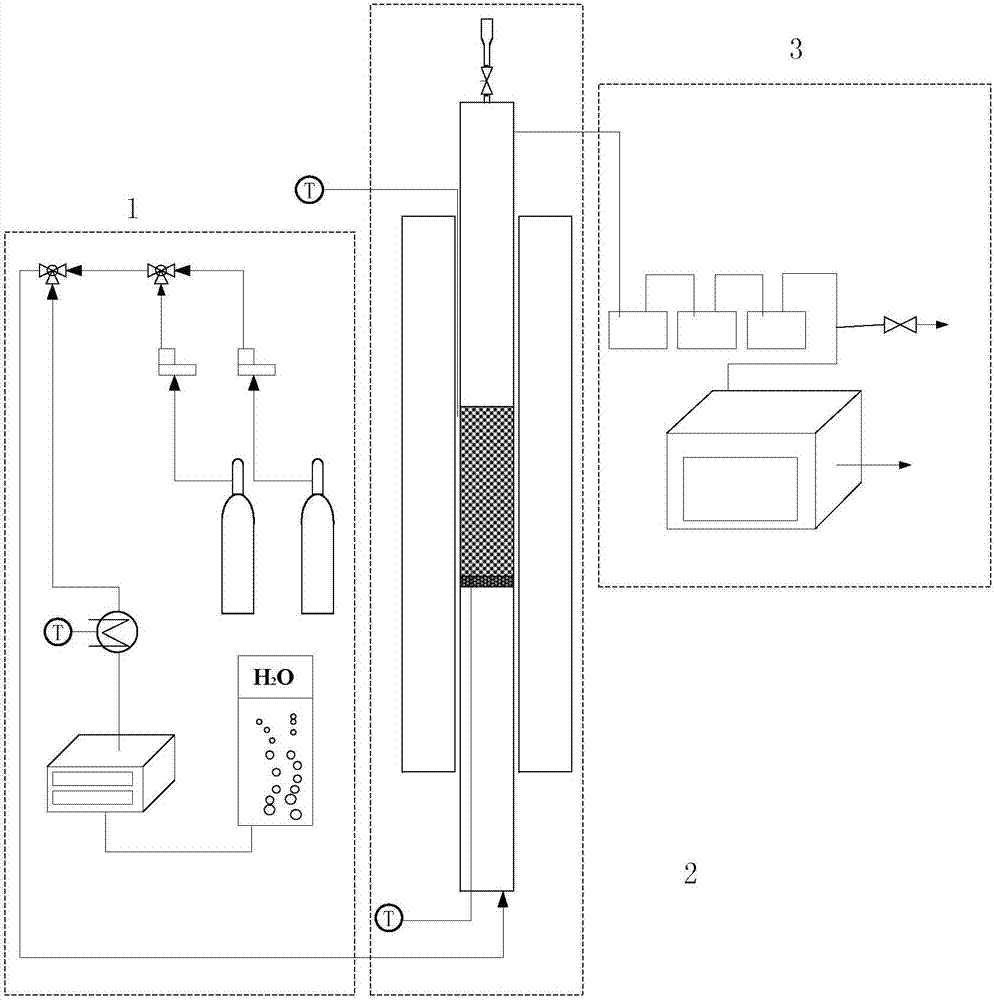

The invention relates to a chemical chain hydrogen production composite oxygen carrier with an anti-carbon property and a preparation method of the chemical chain hydrogen production composite oxygen carrier. The preparation method comprises the following steps: firstly, crushing iron ore by using a crusher, and screening iron ore granules of which the particle size is within 0.2-0.45 mm; adding the iron ore into a wild-mouth bottle with a rubber plug, and vacuuming; preparing a Cu(NO3)2.3H2O solution and a KNO3 solution, uniformly mixing, adding into the wild-mouth bottle with the iron ore through by using a separating funnel, and continuously vacuuming for 1-2 hours; sealing, leaving to stand for 20 hours, and soaking the iron ore into the Cu(NO3)2*3H2O solution and the KNO3 solution; drying the mixture, and calcining at 900-950 DEG C for 4 hours, thereby obtaining the composite oxygen carrier based on the iron ore. The preparation method takes the iron ore as a raw material and is low in price and simple in process, the composite oxygen carrier prepared by using a soaking method is high in reaction activity and good in anti-carbon property, and the prepared hydrogen is high in purity.

Owner:SOUTHEAST UNIV

Air filter for vehicles

ActiveCN104265403AAvoid destructionReduce pollutionCombustion-air/fuel-air treatmentMachines/enginesAir filterEddy current

The invention discloses an air filter for vehicles. The air filter comprises a casing, a separation structure and a flow blocking structure. A filter element is arranged in the casing and separates the casing into an air inlet side casing portion and an air exhausting side casing portion, the air inlet side casing portion is provided with an air inlet, and the air exhausting side casing portion is provided with an air exhausting port. The separation structure is arranged on the side wall of the air exhausting side casing portion and located in the air exhausting side casing portion. The separation structure is provided with an oil gas connector suitable to be connected with a crankshaft ventilation box, and one side of the separation structure facing the filter element is opened. The flow blocking structure is arranged in the separation structure so as to lead oil gas mixtures entering the separation structure to generate eddy currents. According to the air filter for the vehicles, the oil gas mixtures with a certain pressure in the crankshaft ventilation box is prevented from damaging the gas current flow field in the air exhausting side casing portion, pollution of the oil gas mixtures on a sensor disposed in the air filter is reduced, the phenomenon of car deposition and scratching in a cylinder is changed, and the service life of the engine is prolonged.

Owner:GREAT WALL MOTOR CO LTD

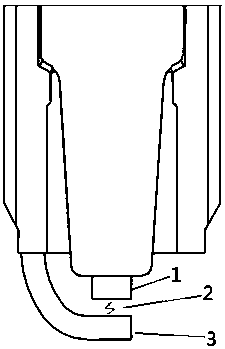

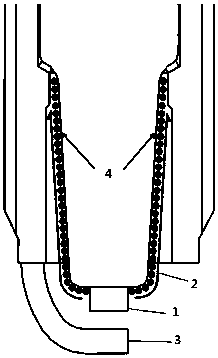

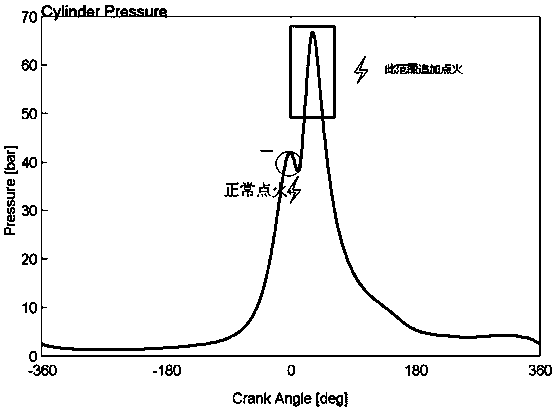

Accumulated carbon self-cleaning method of spark plug

InactiveCN107706745AChange structureImprove carbon depositionSparking plugs manufactureIgnition coilEngineering

The invention discloses an accumulated carbon self-cleaning method of a spark plug. In an initial period of engine starting, an ignition coil is ignited at a normal point of the compression range of an engine and is continued to be ignited during the working process of the engine, accumulated carbon is actively cleaned by continuous ignition during the working process, at the moment, an air door of the engine is completely closed, dangers such as engine tempering and fire flamed-up cannot be caused by continuous ignition of the spark plug, a combustible mixed gas (which is already combusted) is prevented from existing around the engine after normal ignition, secondary carbon accumulation is prevented, and normal running of the engine cannot be affected.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

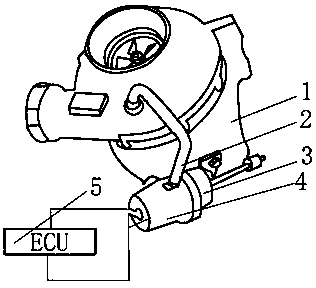

Turbocharger with intelligent control function and control method

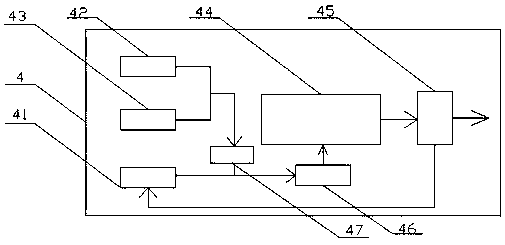

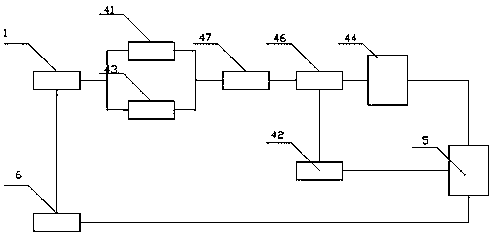

InactiveCN108060987AImprove mechanical agingImprove carbon depositionElectrical controlMachines/enginesTurbochargerComputer module

The invention relates to a turbocharger, in particular to the turbocharger with an intelligent control function. The turbocharger is characterized in that a sensing module is additionally arranged ona bypass valve of the turbocharger, an air pipe of the turbocharger is connected to an electric control unit, the output end of the electric control unit is connected to an ECU of an automobile engine, wherein the electric control unit is composed of an input module, an output module and a main controller, the input module is used for receiving signals transmitted by the sensing module and the ECUof the automobile engine, and the signals are buffered by a storage unit of the input module, then undergo A / D conversion and are transmitted to the main controller; and the main controller processesthe information according to the received information, the processed information is transmitted to the ECU of the automobile engine through the output module, and then an execution command is sent out by the ECU of the automobile engine.

Owner:无锡财尔科技有限公司

Catalyst for preparing olefin through alkane dehydrogenation and preparation thereof, and dehydrogenation method

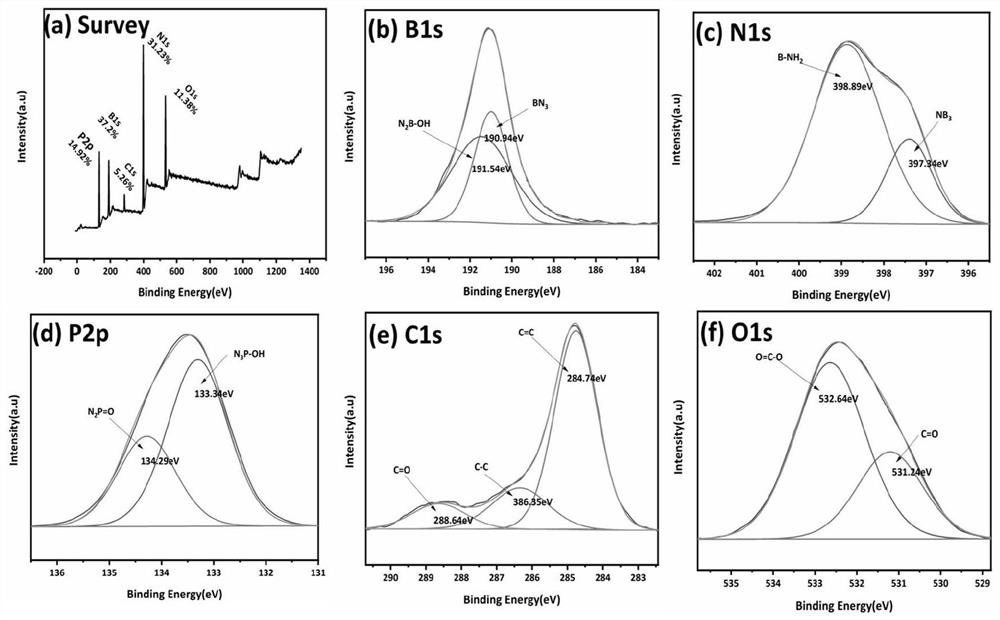

ActiveCN113198513AGood choiceImprove stabilityCatalystsHydrocarbon preparation catalystsAlkanePolymer science

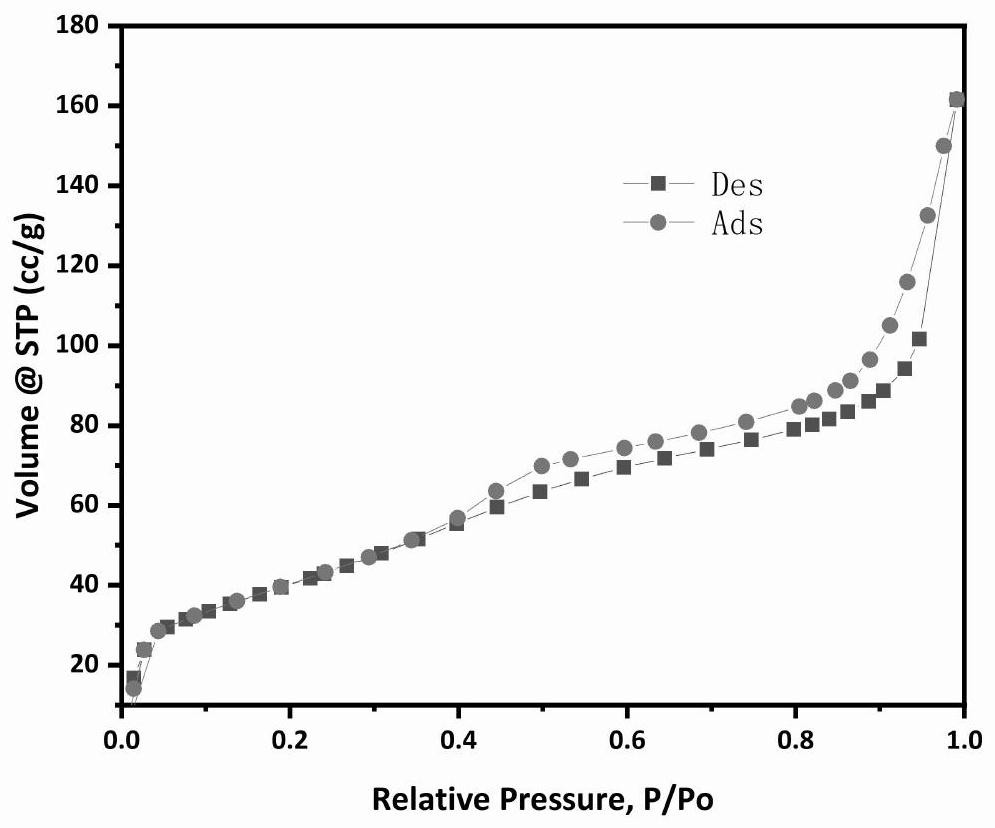

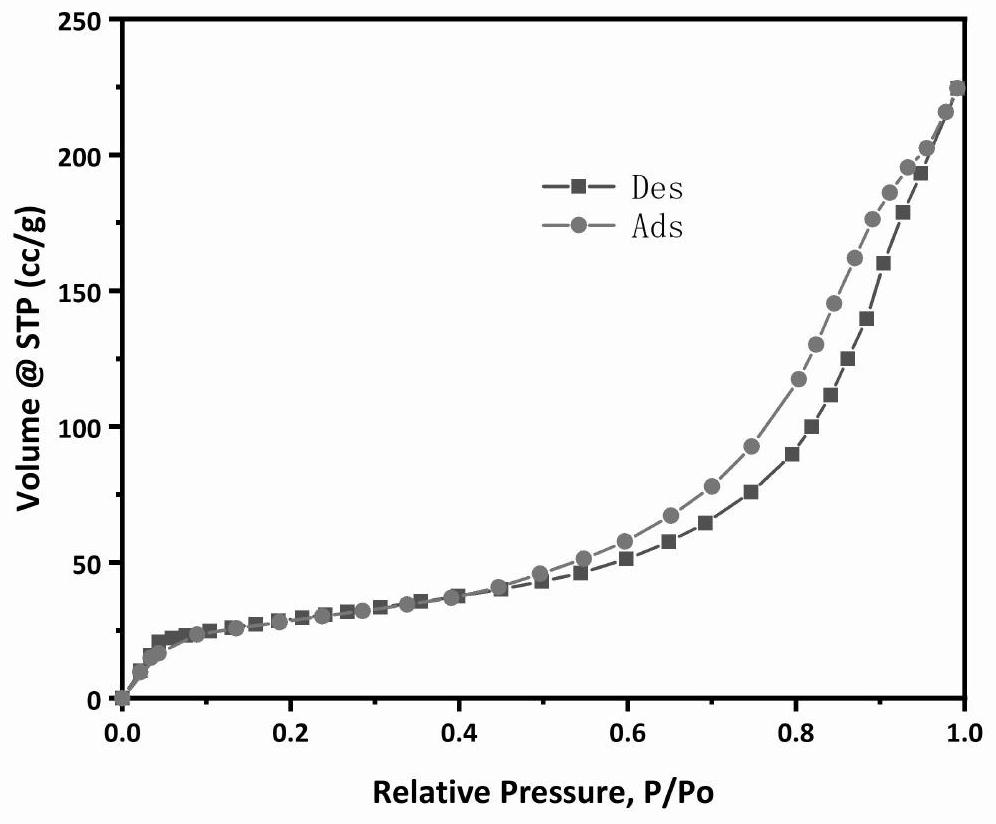

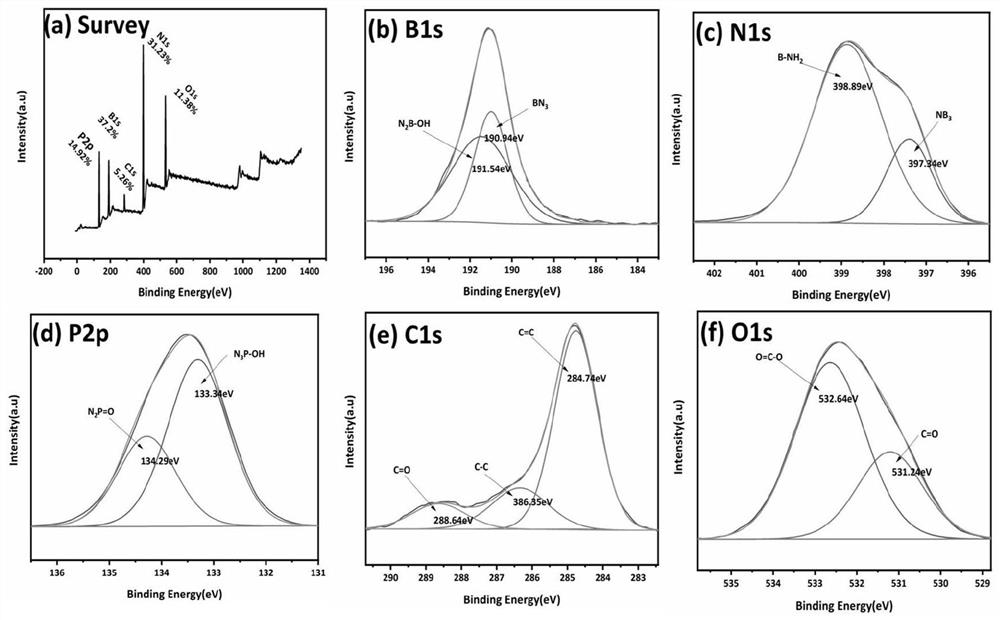

The invention belongs to the technical field of catalytic dehydrogenation, and particularly discloses a preparation method of a catalyst for preparing olefin through alkane dehydrogenation, which comprises the following steps of: recrystallizing a compound raw material capable of providing elements B, P, S and N in a solvent, heating the recrystallized product to 700-1000 DEG C in an ammonia-containing atmosphere at a heating rate of greater than or equal to 5 DEG C / min, and carrying out heat preservation roasting to obtain the catalyst. In the compound raw material, the molar ratio of S to B is greater than or equal to 10; the molar ratio of P to B is greater than or equal to 0.5; and the molar ratio of N to B is greater than or equal to 10. The invention also relates to a catalyst prepared by the preparation method and application of the catalyst in preparation of olefin by direct or oxidative alkane dehydrogenation. Based on the preparation method, a special catalyst can be obtained, and the catalyst has good conversion rate and excellent product selectivity and stability.

Owner:CENT SOUTH UNIV +1

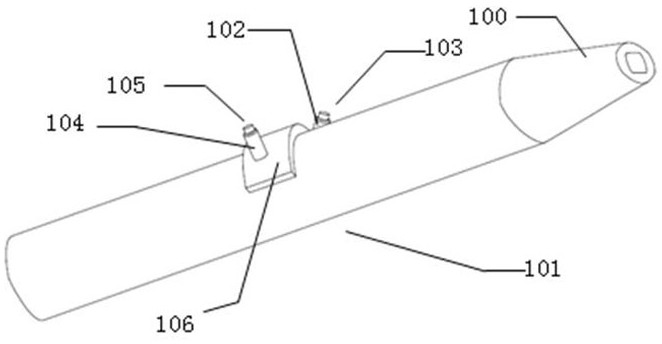

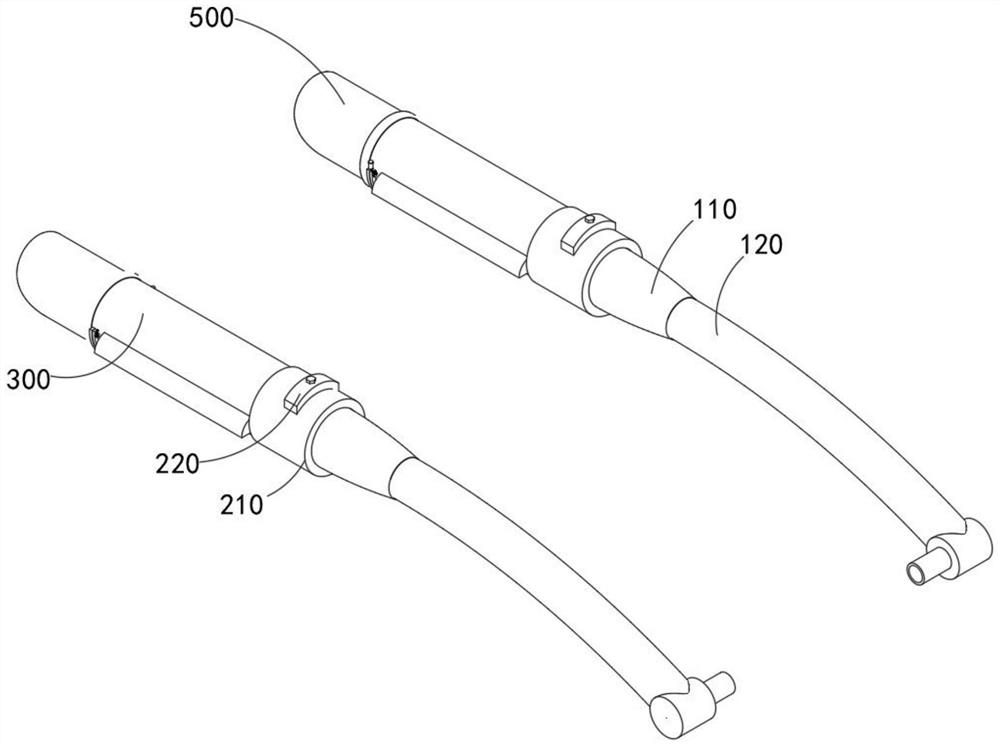

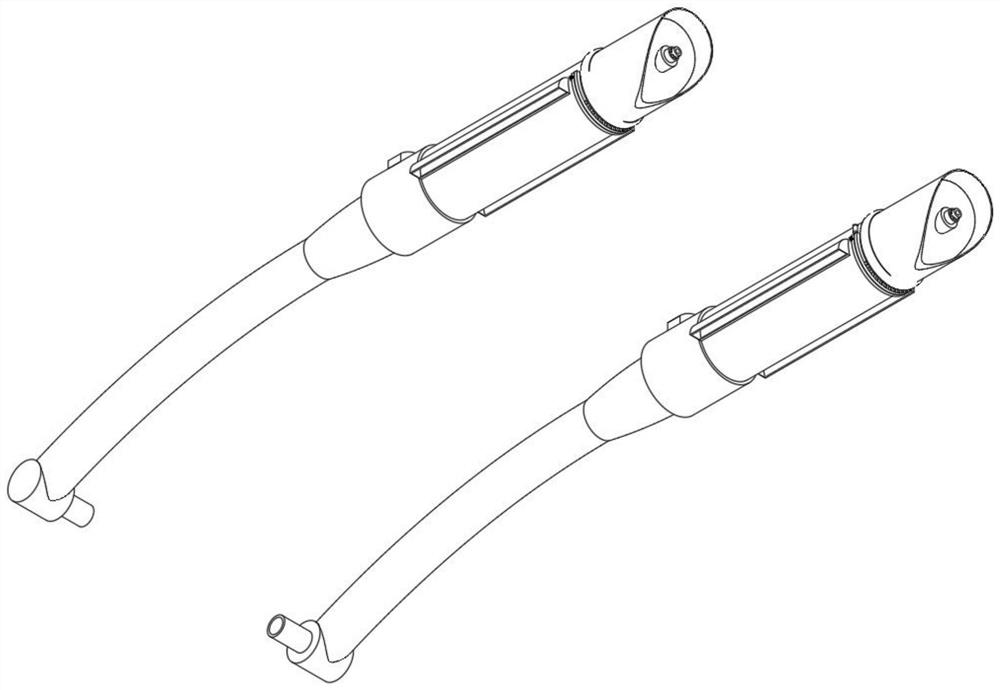

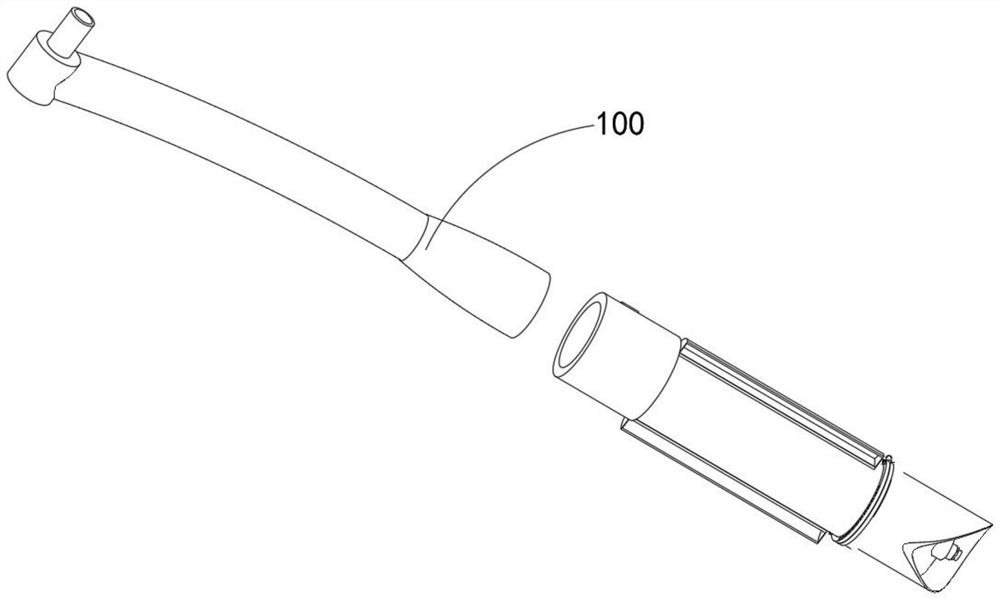

Mouth-nose cooperative use electronic cigarette

PendingCN113633030ASubstance reductionImprove carbon depositionTobaccoEngineeringElectronic cigarette

The invention discloses a mouth-nose cooperative use electronic cigarette. The electronic cigarette comprises a mouth-smoking electronic cigarette module and a nose-smoking module, the mouth-smoking electronic cigarette module adopts one of a steam electronic cigarette and a heat-not-burn electronic cigarette, the nose-smoking module is arranged on the outer side or inside the mouth-smoking electronic cigarette module, the nose-smoking module comprises at least one essence carrier, and essence is placed in the essence carrier. By means of the mode, according to the mouth-nose cooperative use electronic cigarette, after the essence can be partially or completely transferred into the nose-smoking module from the mouth-smoking electronic cigarette module, the essence utilization rate is increased, the transmission efficiency and the distinguishing accuracy of aroma molecules reaching the olfactory nerves of the nasal cavity are improved, the use risk of the electronic cigarette caused by the fact that the essence, the essence solvent and the essence related substances enter the lung from the mouth is reduced, the types of the essence capable of being used by the electronic cigarette can be increased through the nose-smoking module, and the flavoring technology of tobacco tar, solid smoke cartridge, tobacco paste and other tobacco materials can be simplified.

Owner:ZHANGJIAGANG ALIEN NEW MATERIAL TECH CO LTD

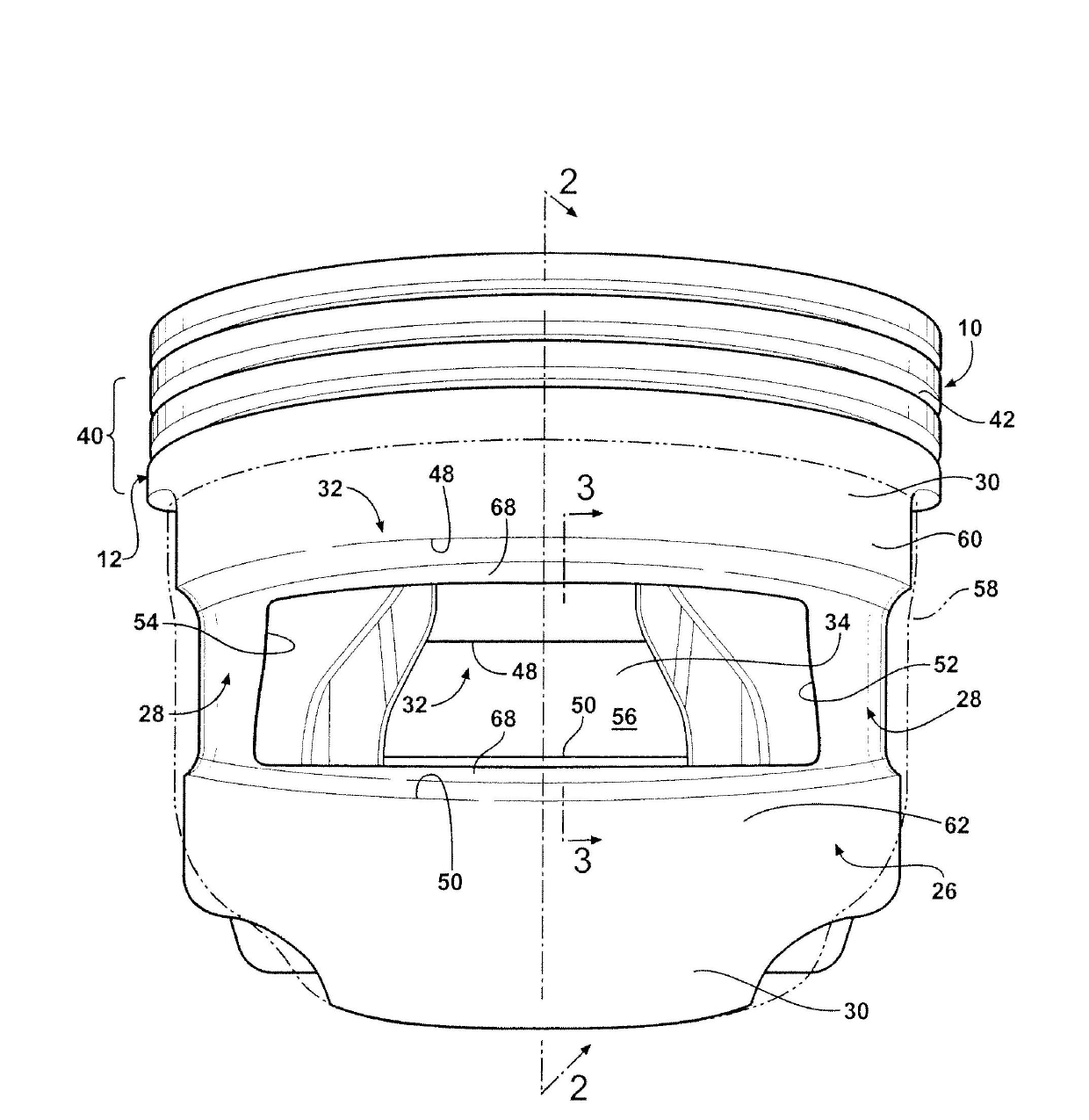

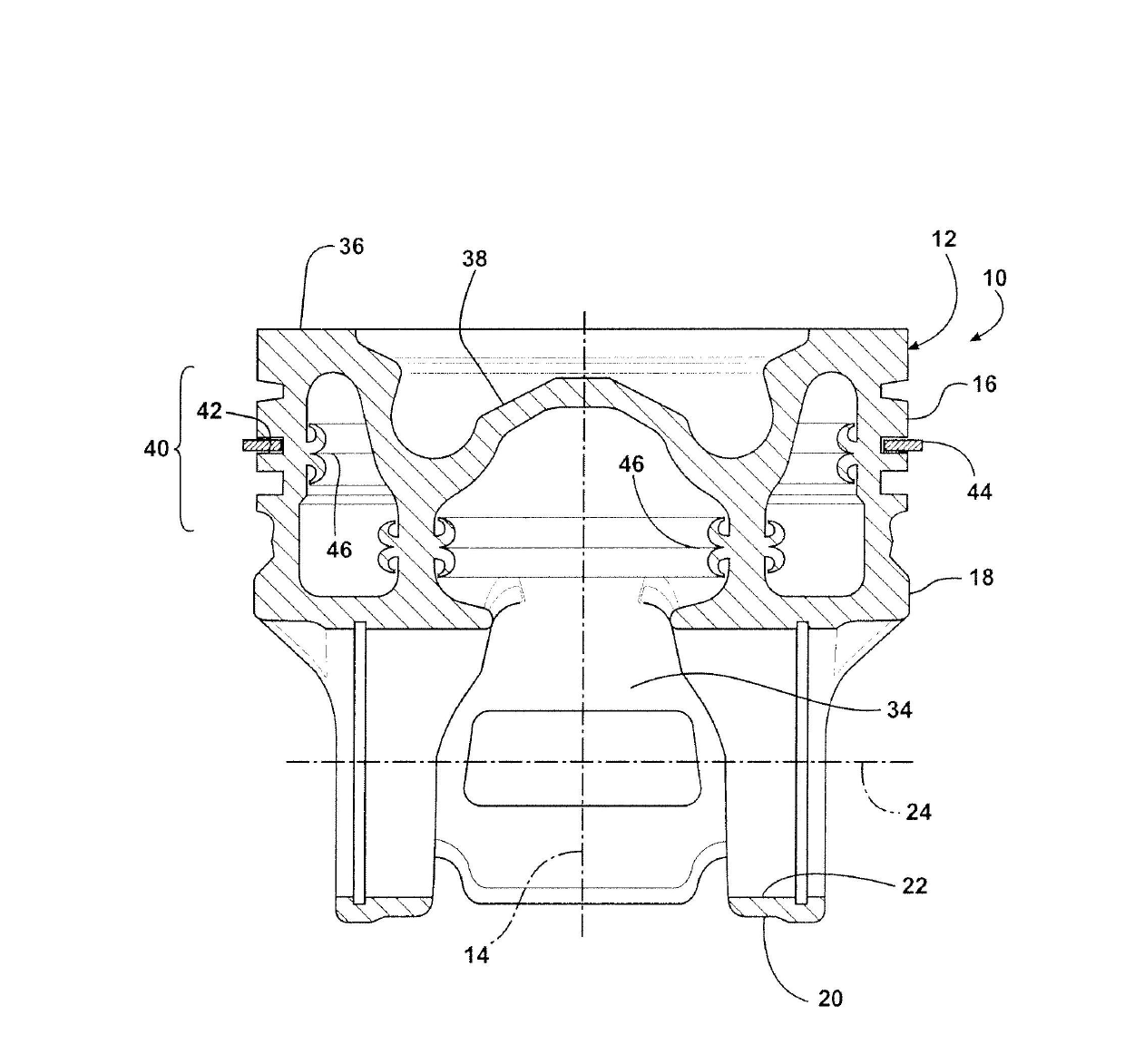

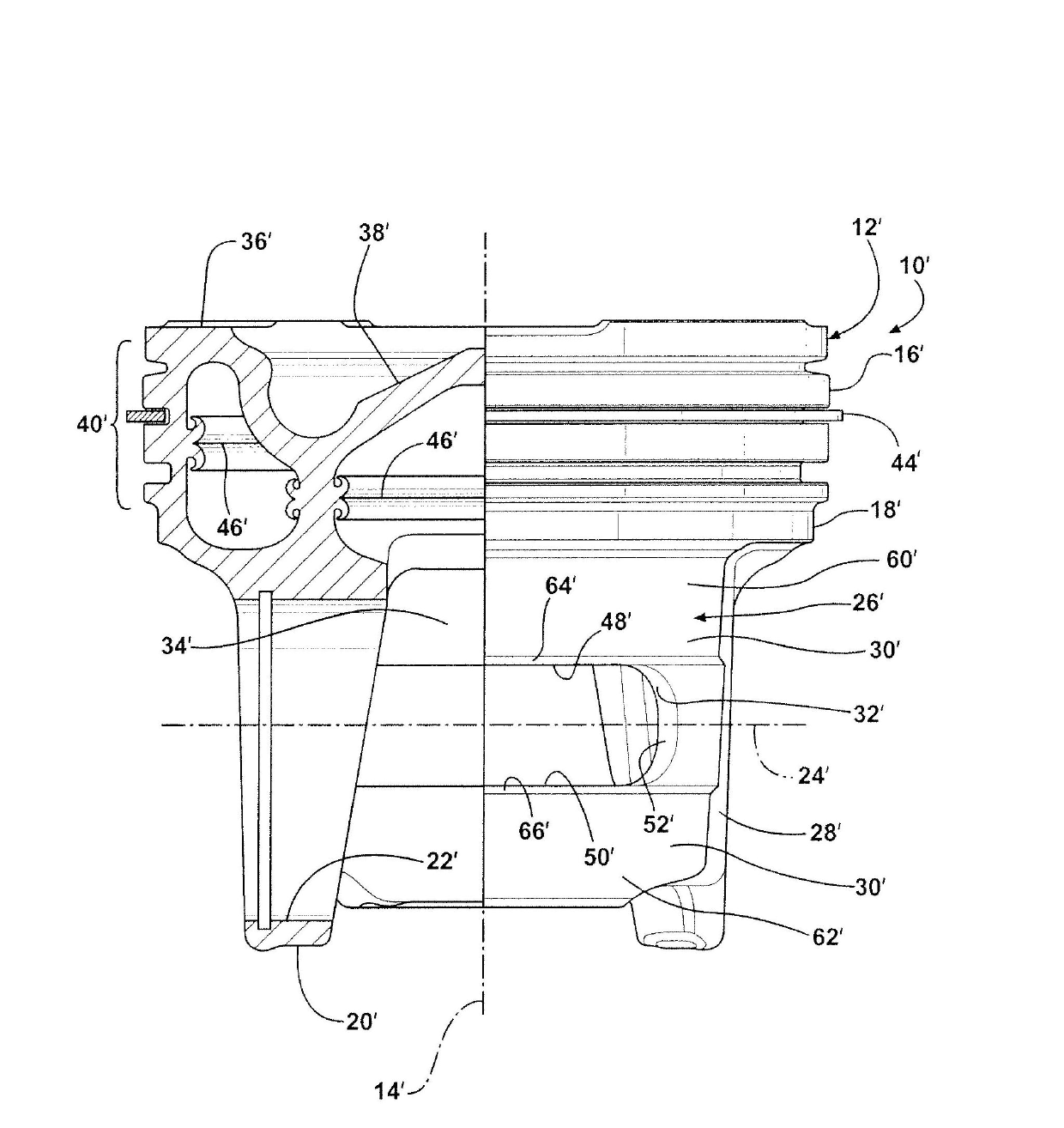

Piston with a skirt having oil flow slots and method of construction thereof

InactiveCN102667126ALow dynamic frictionGood guiding effectInternal combustion piston enginesPlungersMechanical engineering

A piston has a pair of diametrically opposite skirt portions with convex outer surfaces. Each skirt portion has opposite side edges extending substantially parallel to a central axis of the piston to a free end. The skirt portions each have a recessed slot extending radially into the convex outer surface to a recessed surface. The recessed surface extends fully across the convex outer surface to the side edges and separates an upper band section of the convex outer surface from a lower band section of the convex outer surface.

Owner:FEDERAL MOGUL CORP

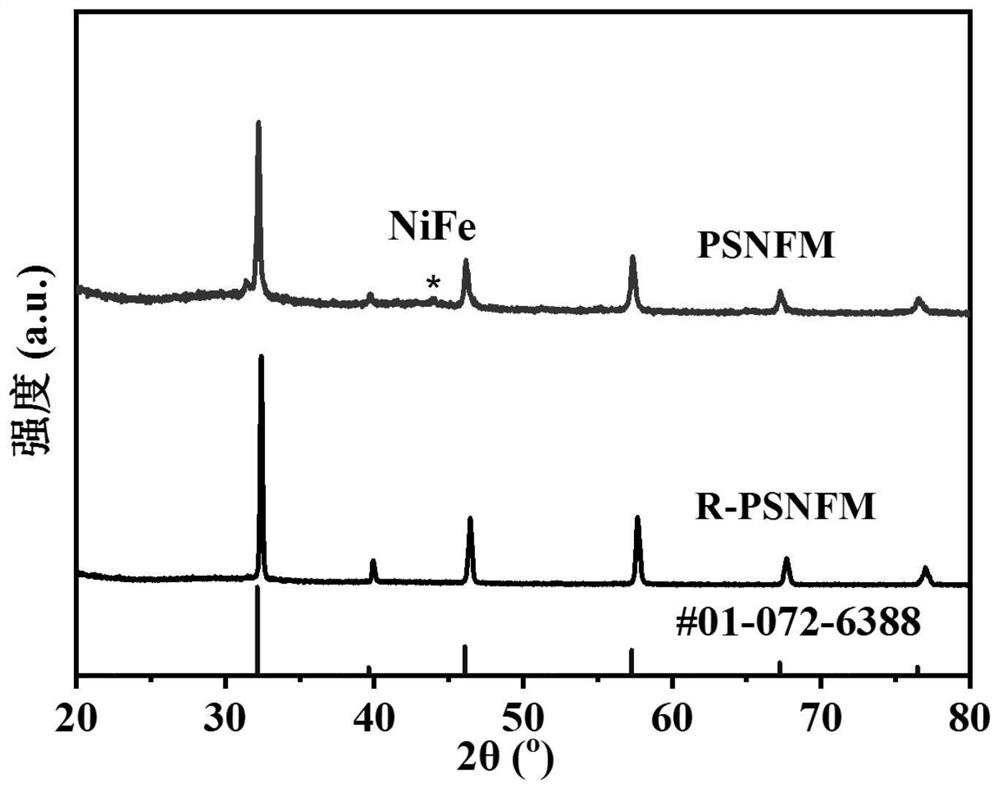

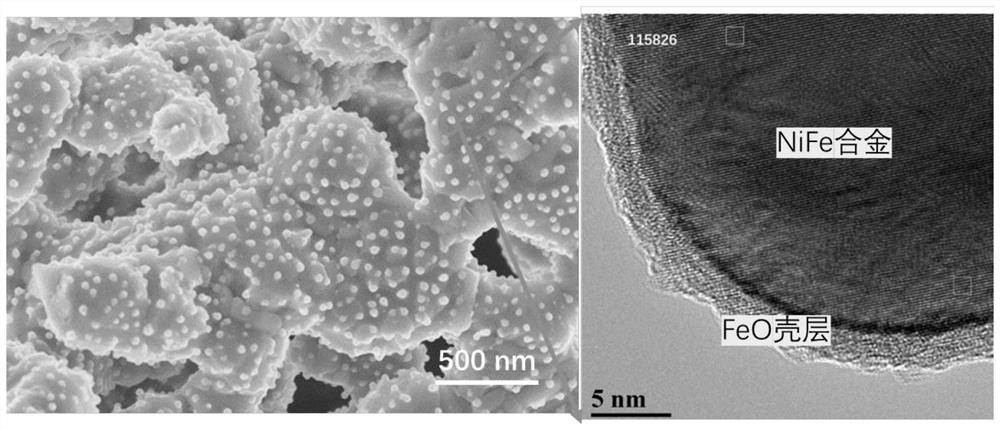

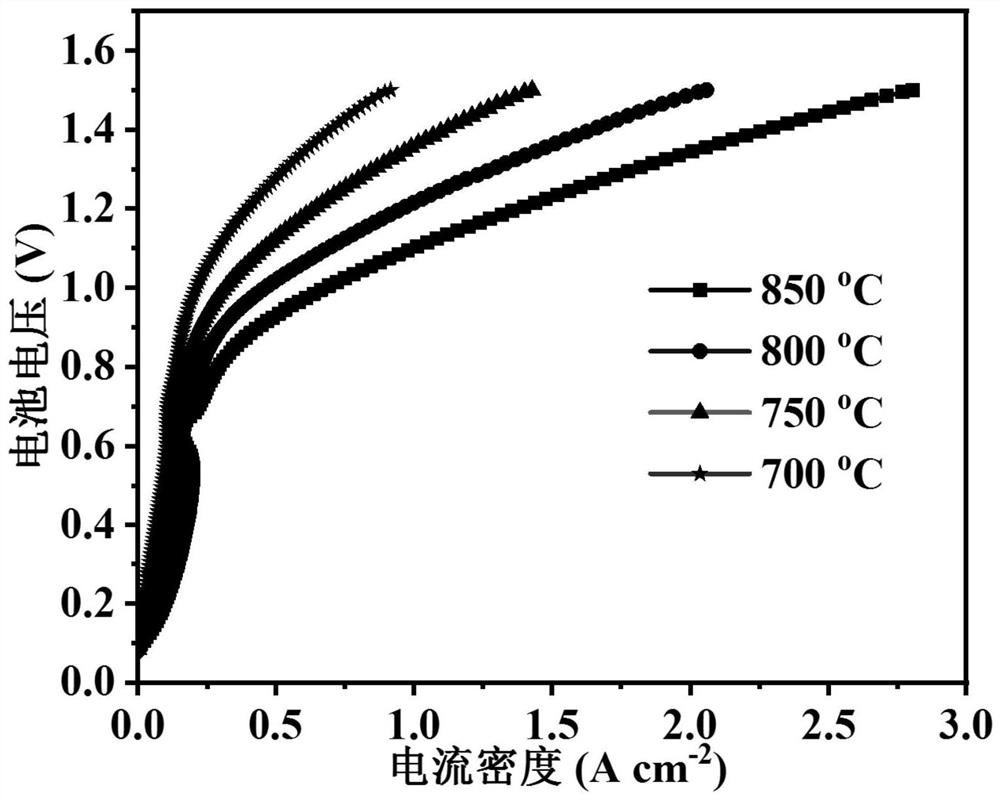

In-situ precipitation method self-assembled core-shell structure nanoparticle modified perovskite oxide electrode material, preparation method and application thereof

PendingCN113948714AHigh reducing activityGood control effectCell electrodesSolid electrolyte fuel cellsFuel cellsNanoparticle

The invention discloses an in-situ precipitation method self-assembled core-shell structure nanoparticle modified perovskite oxide electrode material, a preparation method and application thereof. The preparation method comprises the steps: preparing a perovskite oxide precursor, and obtaining core-shell structure nanoparticles of NiFe alloy coated with ion oxide FeO through an in-situ reduction precipitation method, wherein the nanoparticles are loaded on the surface of the perovskite oxide. According to the invention, the electrode material is applied to a cathode of a solid oxide electrolytic cell for high-temperature carbon dioxide electrolysis, so that the catalytic activity of the cathode material to carbon dioxide is effectively improved; as the anode of the solid oxide fuel cell, the electrode material has high fuel oxidation performance, and can improve the carbon deposition resistance; and the method has the characteristics of simple preparation, controllable conditions and obviously improved performance, and has wide application prospects in the field of preparation of solid oxide electrolytic cell cathodes and solid oxide fuel cell anodes.

Owner:SOUTH CHINA UNIV OF TECH

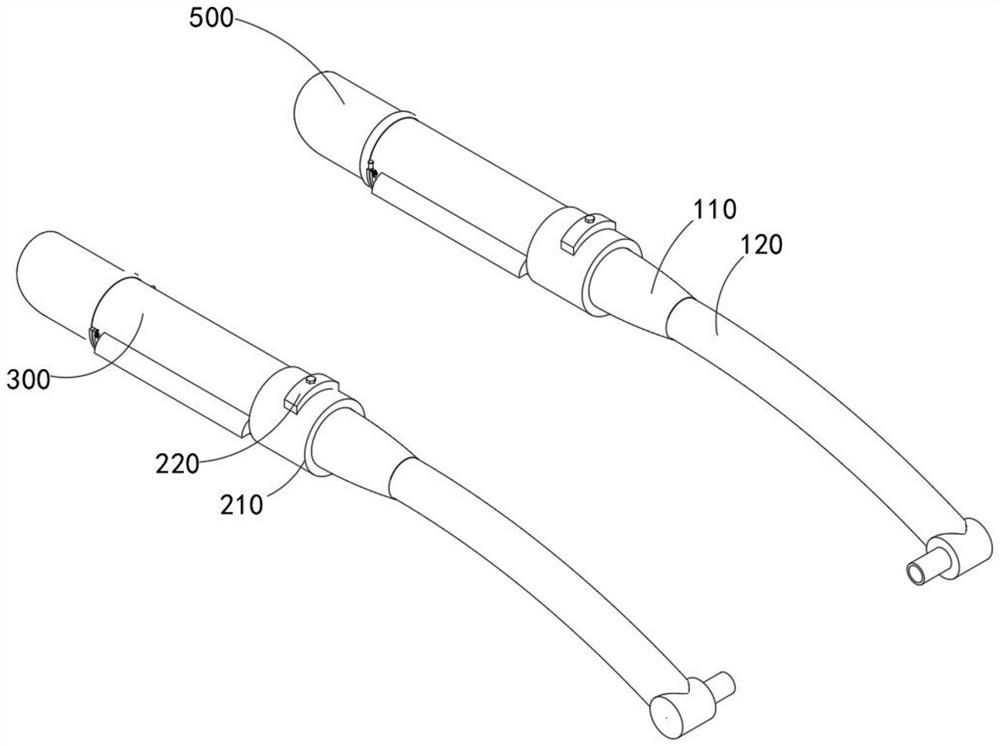

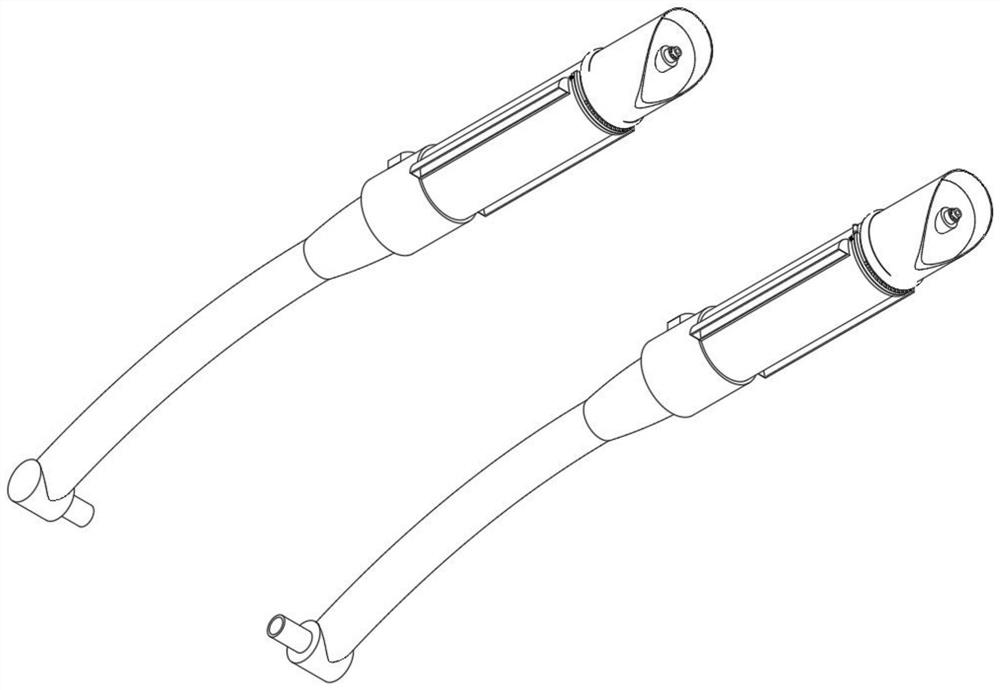

Muffler for motorcycle exhaust pipe

ActiveCN113339118BIncrease profitQuick disassemblyExhaust apparatusSilencing apparatusWater circulationDisplacement control

The invention discloses a muffler for a motorcycle exhaust pipe and its assembly, including a connecting mechanism, a waste gas displacement control mechanism, a sound-absorbing combination, a water circulation heat dissipation combination and an assembled tail end mechanism. The connecting mechanism has a built-in cavity, and the exhaust gas discharge The volume control mechanism includes a fine-tuning part and an exhaust part, and the exhaust part includes a safety outer cylinder, an inner core ring welded in the middle of the inner cavity of the safety outer cylinder, and an anti-seepage pad installed outside the safety outer cylinder, The sound-absorbing combination includes a jacket and an output pipe located in the middle of the jacket. By opening an inwardly recessed annular notch on the inner side of the outer end of the jacket, at this time, insert the external port on the inner side of the ring, and use the fixing piece to fix the jacket and the external port, and use the ring at the inner end of the cooling member to The protrusion pair interferes with the fixation of the inner cylinder, so that the exhaust pipe can be quickly disassembled, thereby solving the problem that the exhaust pipe is difficult to disassemble today.

Owner:XINGHUA FUBANG MACHINERY

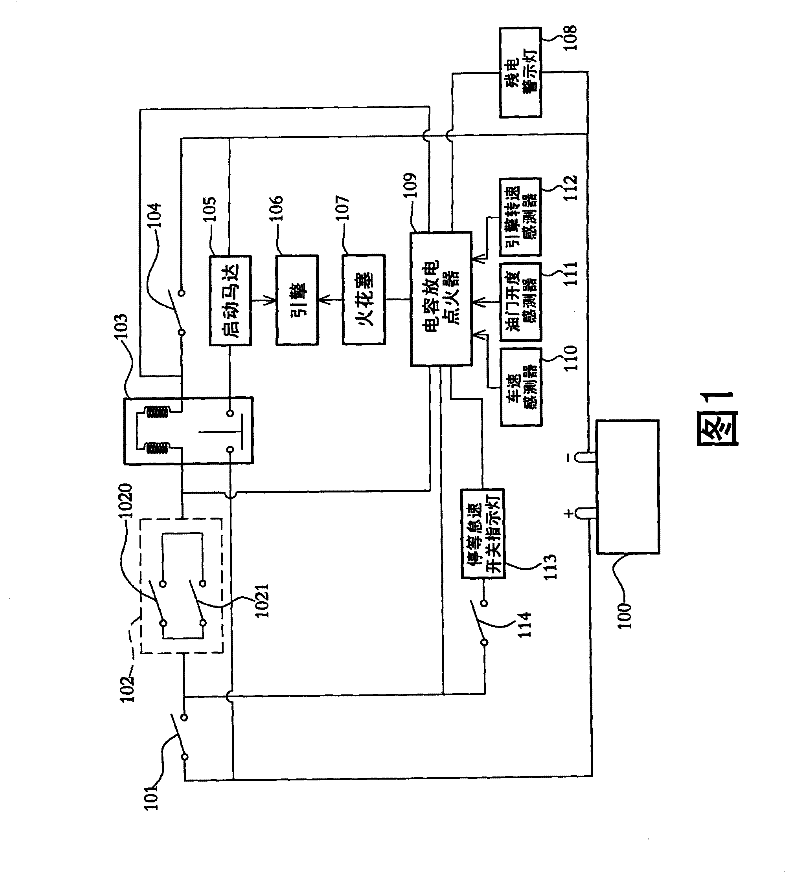

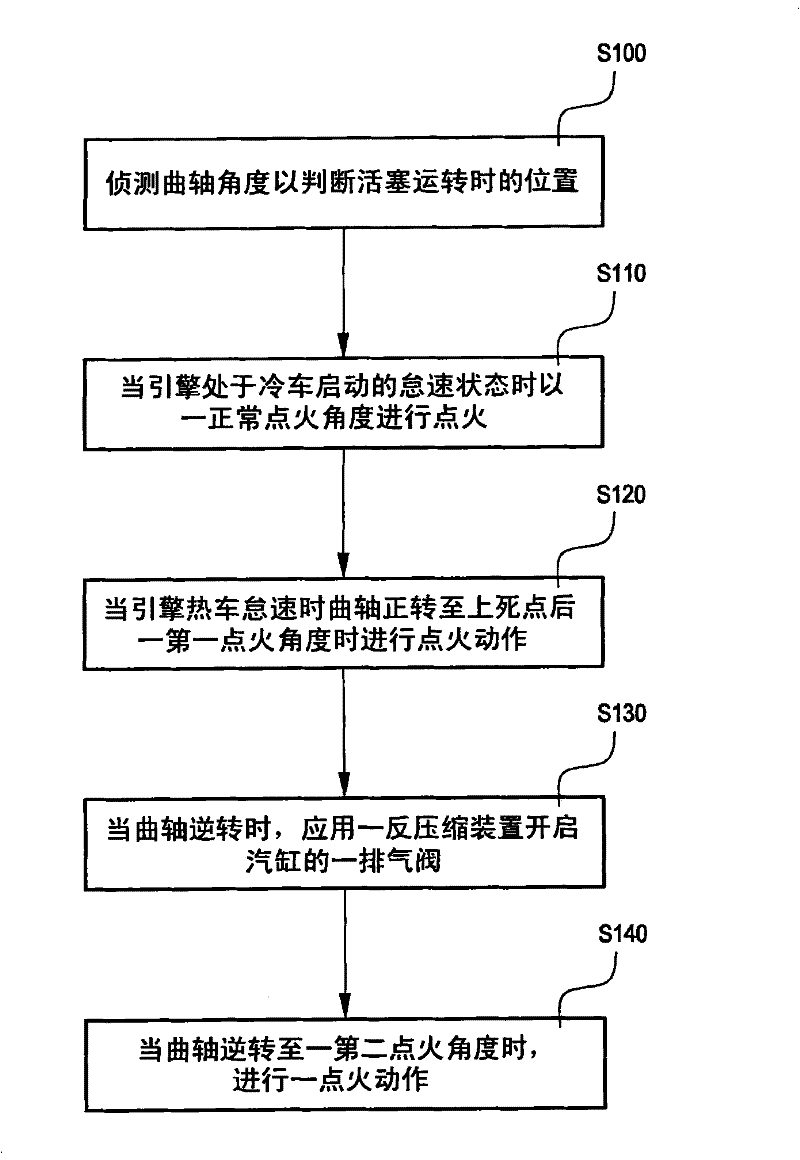

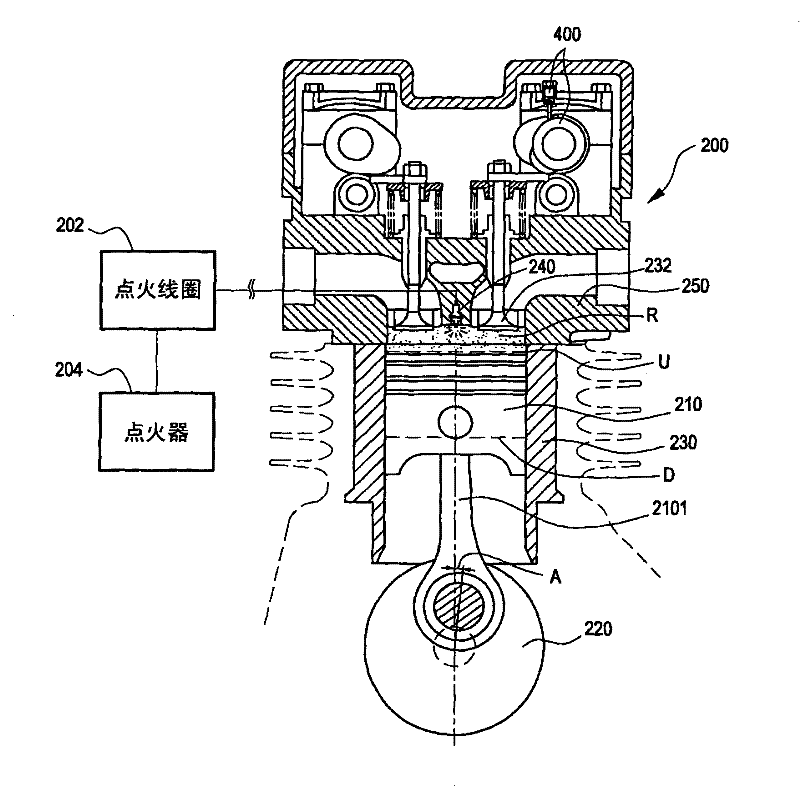

Method for controlling idling mode of engine

InactiveCN101649801BAvoid erosionExtend your lifeElectrical controlMachines/enginesCylinder headResidual oil

Owner:KYMCO

Catalyst for dehydrogenating alkanes to olefins and its preparation and dehydrogenation method

ActiveCN113198513BGood choiceImprove stabilityCatalystsHydrocarbon preparation catalystsAlkanePtru catalyst

The invention belongs to the technical field of catalytic dehydrogenation, and specifically discloses a method for preparing a catalyst for alkane dehydrogenation to olefins. The compound raw materials that can provide B, P, S, and N elements are recrystallized in a solvent, and then the recrystallized product is In an ammonia-containing atmosphere, the temperature is raised to 700-1000°C at a heating rate greater than or equal to 5°C / min, and heat preservation is carried out to obtain the catalyst; in the compound raw materials, S: B element moles The ratio is greater than or equal to 10; the P:B element molar ratio is greater than or equal to 0.5; the N:B element molar ratio is greater than or equal to 10. The invention also includes the catalyst prepared by the preparation method and the application of the catalyst in the direct or oxidative dehydrogenation of alkanes to prepare alkenes. Based on the preparation method, the present invention can obtain a special catalyst, and the catalyst has good conversion rate, and simultaneously has excellent product selectivity and stability.

Owner:CENT SOUTH UNIV +1

Anti-carbon deposit injector

ActiveCN105221314BImprove carbon depositionExtended service lifeFuel injection apparatusMachines/enginesFuel tankEngineering

The invention discloses an anti-carbon fuel injector, which comprises: a main body, the main body has a casing, a plunger, a nozzle and a controller, a cavity is arranged in the casing, the plunger is sealed and slidably fitted in the cavity, and the casing is There is a liquid inlet hole and a liquid return hole, and the controller is connected to the plunger drive so that the controller drives the plunger to slide in the cavity. The bottom of the cavity is provided with a liquid outlet hole, a liquid inlet hole and a liquid return hole. The holes are respectively connected with the oil circuit of the fuel tank; the reversing valve, the position of the fuel injection state and the position of the non-fuel injection state are set on the reversing valve. When the controller drives the plunger and drives the reversing valve to the position of the non-fuel injection state, The liquid inlet hole is connected with the cavity, and at the same time, the liquid outlet hole of the cavity is connected with the liquid return hole through the reversing valve and is in a disconnected state with the nozzle; when the controller drives the plunger and drives the reversing valve to be in the oil injection state At this time, the plunger blocks the liquid inlet hole, and at the same time, the liquid outlet hole of the cavity communicates with the nozzle through the reversing valve and is in a disconnected state with the liquid return hole. The invention can effectively improve the carbon deposit of the fuel injector and increase the service life of the fuel injector.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

A method for comprehensively treating organosilicon by-products

ActiveCN103613608BAvoid cleavageAvoid diseconomiesGroup 4/14 element organic compoundsPtru catalystReaction temperature

The invention relates to a method for comprehensively treating organosilicon by-products. The organosilicon by-products, high boilers, azeotropes, low boilers, and methyltrichlorosilane are mixed in a volume ratio of 1: (0.1~1): (0.1~ 1): (0.1~1), after mixing, it is integrated into dimethyldichlorosilane through disproportionation reaction under the Lewis catalyst; the reaction temperature is 280~350°C, and the reaction time is 1~6h , and during the reaction process, the pressure is 3-10Mpa as the filling amount of the material, the temperature rise and the composition of the organochlorosilane change. The invention is simple and easy to implement, has a high dimethyl selectivity, and converts by-products that cause hidden dangers to safety and the environment into dimethyldichlorosilane through a rearrangement reaction, thereby generating both economic value and social benefits.

Owner:内蒙古恒业成有机硅有限公司

A chemical chain hydrogen production composite oxygen carrier with anti-carbon deposition properties and preparation method thereof

ActiveCN105754681BLow costUniform particlesCatalyst activation/preparationHydrogen productionCompound (substance)Oxygen

The invention relates to a chemical chain hydrogen production composite oxygen carrier with anti-carbon deposition properties and a preparation method thereof. First, the iron ore is crushed with a crusher, and the iron ore particles with a particle size range of 0.2-0.45mm are screened out; the iron ore is added into a jar with a rubber stopper, and vacuumized; the preparation of Cu(NO3 )2 3H2O solution and KNO3 solution and mix evenly, add the jar that is filled with iron ore through the separatory funnel, continue vacuumizing for 1-2 hours; Seal and let stand for 20 hours, carry out Cu(NO3) 2 3H2O impregnation of iron ore with solution and KNO3 solution; the mixture was dried and calcined at a temperature of 900-950°C for 4 hours to prepare a composite oxygen carrier based on iron ore. The main raw material of the method is iron ore, the price is low, the process is simple, the composite oxygen carrier prepared by the impregnation method has high reactivity, and has anti-coking ability, and the hydrogen produced has high purity.

Owner:SOUTHEAST UNIV

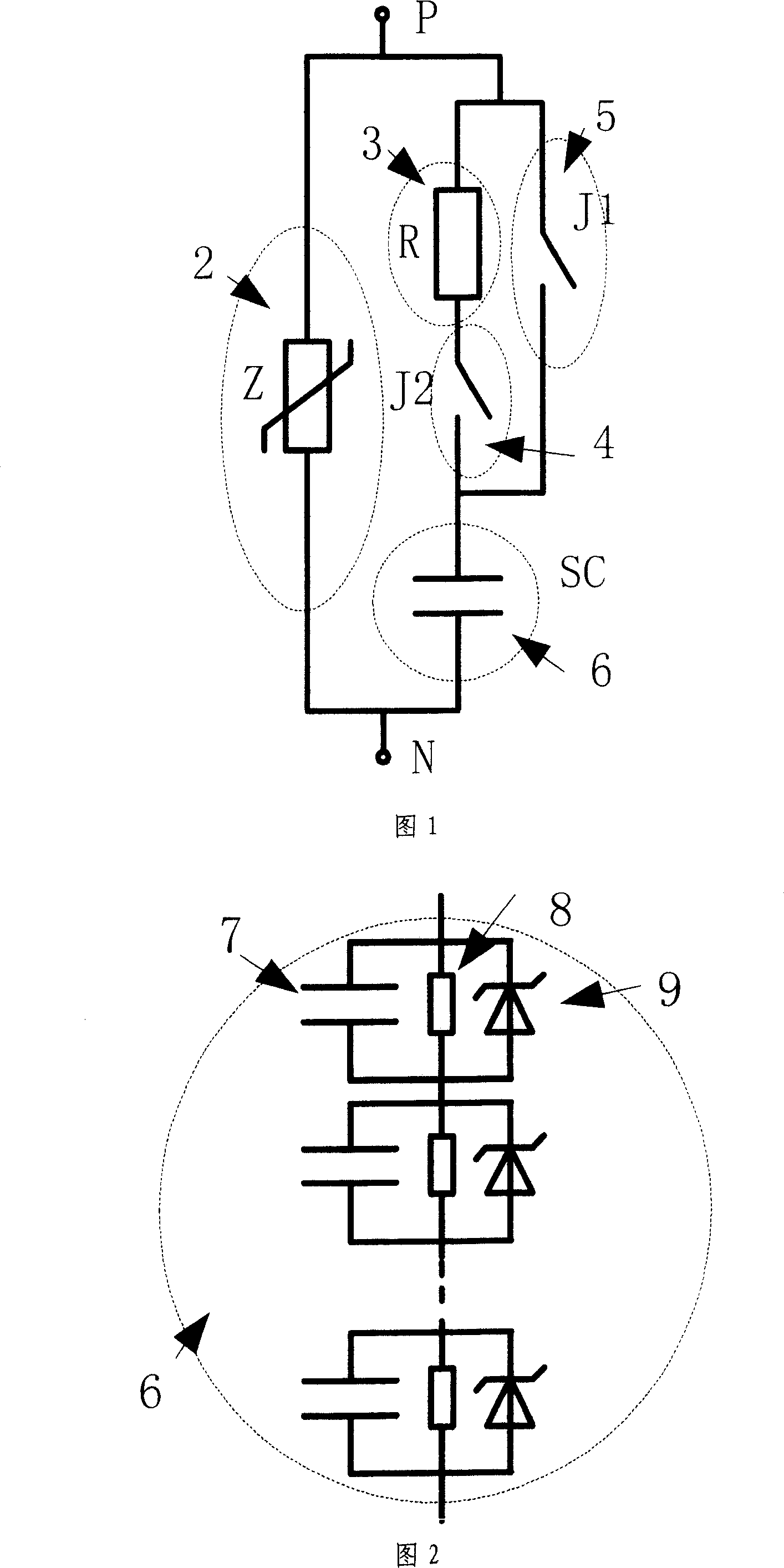

Transient power compensator for automobile storage battery

InactiveCN100364207CIncrease motivationIncrease fuel consumptionBatteries circuit arrangementsElectric powerCapacitanceEngineering

Present invention provides car accumulator transient state power compensator, belonging to car power supply technology field. It contains pressure responsive resistor, charging resistor, charging relay, compensation relay, transient state energy storage module, wherein transient state energy storage module consisting of series connected several super capacity modules, each super capacity module consisting of parallel connected super capacitor, static equalizing resistor, and dynamical voltage-sharing voltage stabilizing diode. Said invention has advantage of effectively compensating car shock load current, suppressing power supply voltage pulse and ripples, improving car power, oil consumption, carbon deposition, tail gas performance, and prolonging accumulator service life.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

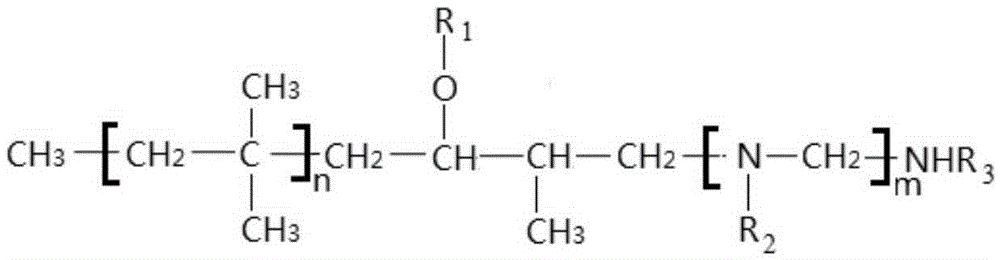

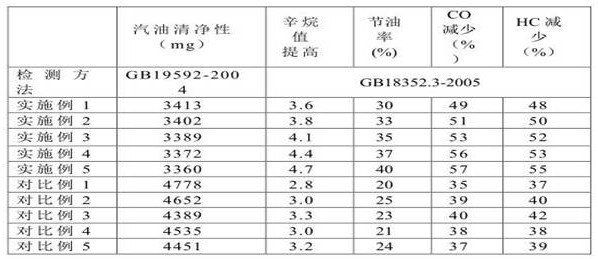

Gasoline additive and preparation method thereof

InactiveCN112625766AImprove pass rateSimple manufacturing methodLiquid carbonaceous fuelsFuel additivesGlycolurilOil additive

The invention discloses a gasoline additive, which is characterized by being prepared from the following components by weight: 4-6 parts of a polyethylene glycol modified metal organic nano material, 30-40 parts of solvent oil, 2-4 parts of tetrahydroxy glycoluril, 3-5 parts of 2-benzyl tetrahydropyrrolo[3, 4-c]pyrrole-1, 3-dione, 1-2 parts of quaternary ammonium salt-15 modified polyether amine, 0.5-1 part of diphenylguanidine, and 4-8 parts of polyether amine. The invention also provides a preparation method of the gasoline additive and an application of the gasoline additive in gasoline. The gasoline additive provided by the invention can effectively improve the quality of gasoline, has an obvious oil-saving effect and multiple functions, and is environment-friendly and safe to use; gasoline can be promoted to be fully combusted and decomposed, the lubricity, cleanliness and corrosion resistance of an automobile are improved, power is enhanced, the service life of an engine is prolonged, automobile tail gas emission is reduced, and air and environment pollution is reduced.

Owner:泗县唯澳生物技术开发有限公司

Novel ion source for time-of-flight mass spectrometer

InactiveCN102789953AImprove collision efficiencyImprove ionization efficiencyIon sources/gunsIonizationMass spectrum analysis

The invention relates to an external ion source for a time-of-flight mass spectrometer. The external ion source comprises a gas sample inlet, an ionization chamber, a filament, a slit, a repulsion electrode, a magnetic pole, an ion lead-out slit, a heating rod, a temperature probe and a fixing rod. An external ion source device disclosed by the invention takes the gas sample inlet as a starting point and the repulsion electrode as a circle center; the fixing rod, the filament, the slit, the temperature probe, the heating rod, a dual-gas sample inlet, the fixing rod and the magnetic pole are orderly arranged on the ionization chamber in a clockwise direction; the filament, the slit, the repulsion electrode and the magnetic pile are on the same axis; the ion lead-out slit is parallel to the axis, and the repulsion electrode is an ellipse repulsion electrode. Compared with the prior art, the time-of-flight mass spectrometer has the advantages of being simple in structure, compact in structure, light in weight, less in energy consumption, high in ionization rate and convenient to clean and maintain; a multi-channel gas sample inlet is convenient to carry out inner reaction of a plurality of gas ion sources; the ion sources are heated unilaterally, the energy consumption and deposited carbon are reduced, and the time-of-flight mass spectrometer is suitable for an online and portable time-of-flight mass spectrometer ion source.

Owner:ANHUI USTC JIANCHENG HAISHENG TECH

Self-cleaning injectors

ActiveCN105240180BImprove carbon depositionExtended service lifeFuel injection apparatusMachines/enginesCombustionCarbon particle

The invention discloses a self-cleaning oil injector. The self-cleaning oil injector comprises a body and a reversing valve. The body is provided with a shell, a plunger, a nozzle and a controller. A cavity is formed in the shell. The plunger is in sealing sliding fit in the cavity. The shell is provided with a liquid inlet hole and a liquid returning through hole. The controller is in transmission connection with the plunger. A liquid outlet through hole is formed in the bottom end of the cavity. The oil inlet hole and the oil returning through hole are communicated with an oil path of an oil tank. The reversing valve is provided with a nozzle connecting pipe, the nozzle connecting pipe is communicated with the nozzle through a spiral bent channel, and the reversing valve is provided with an oil injecting state position and a non-oil-injecting sate position. According to the self-cleaning oil injector, the accumulated carbon on the inner wall of a fuel channel in the oil injector can be reduced, carbon particles or colloidal materials on the inner wall of a fuel channel at the lower end of the oil injector are cleaned, the particles or colloidal materials generated after combustion in an air cylinder are more hardly to reach the surface of a valve element, the carbon is prevented from being accumulated at the valve element, and accordingly the service life of the oil injector is prolonged.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

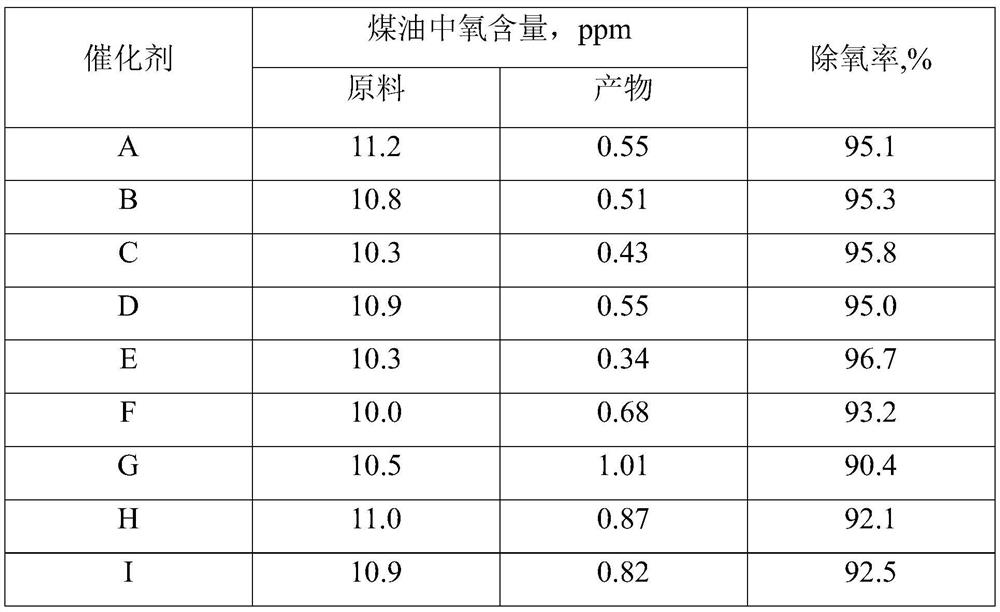

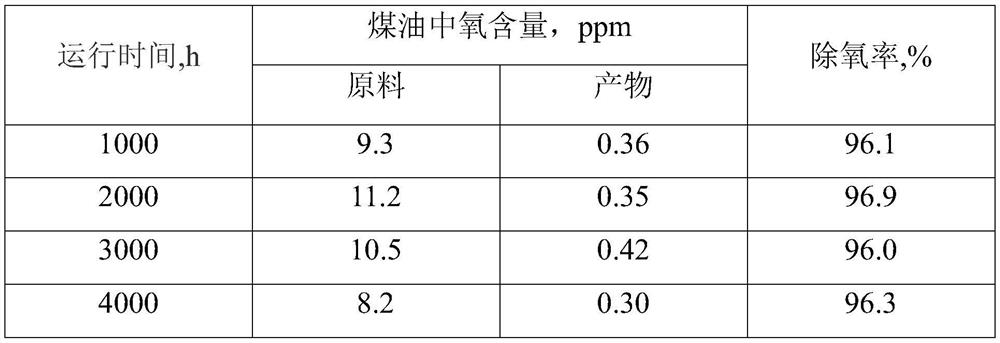

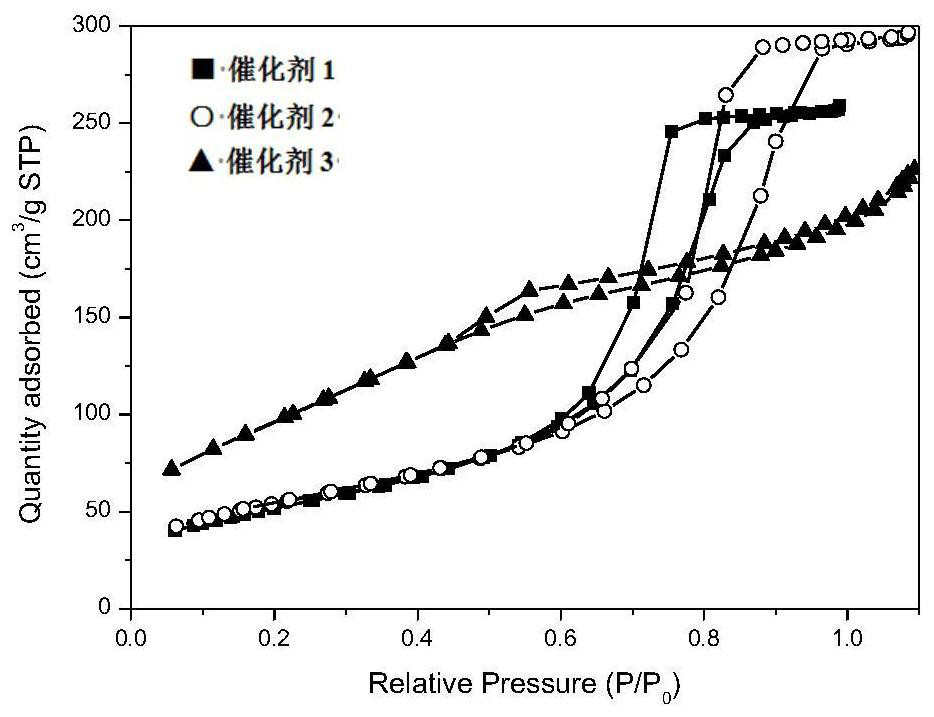

A method for removing dissolved oxygen in oil products

ActiveCN112899012BShorten the diffusion distanceFacilitated DiffusionCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

Owner:SINOPEC JINLING PETROCHEMICAL CO LTD

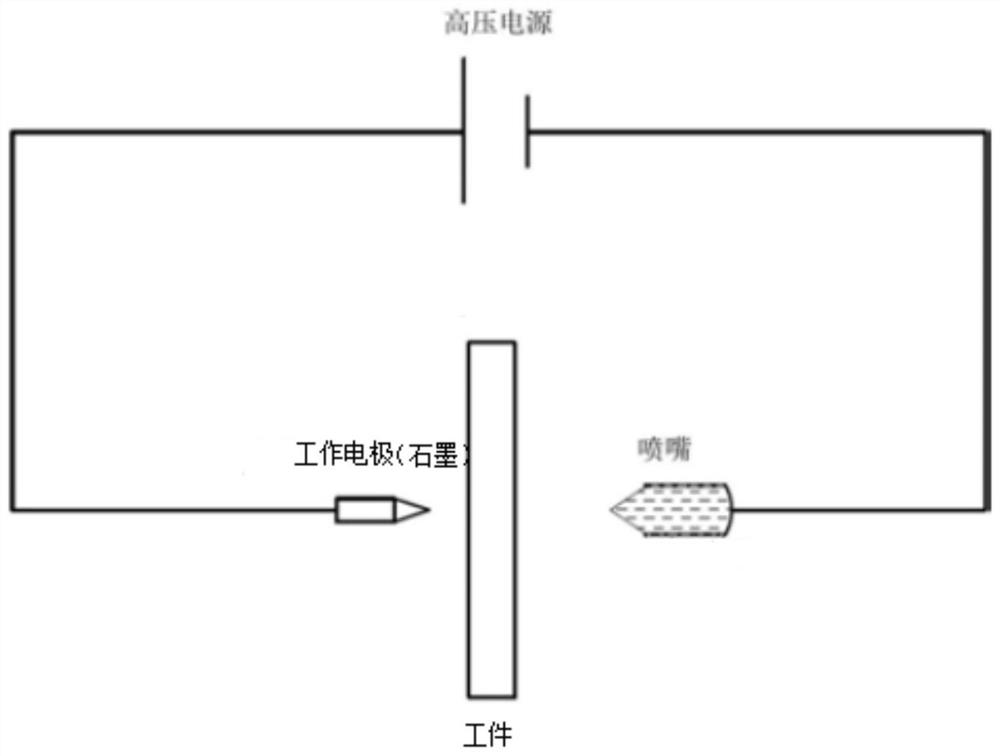

Machining device and method for machining ultrafine hole by adopting graphite fine needle electric discharge

PendingCN111790958AImprove carbon depositionSmall sizeElectrical-based machining electrodesElectric dischargeGraphite electrode

The invention discloses a machining device for machining an ultrafine hole by adopting graphite fine needle electric discharge, and relates to the technical field of fine hole electric discharge. Themachining device for machining the ultrafine hole by adopting the graphite fine needle electric discharge aims at solving the problems that a copper electrode cannot meet the size precision requirement of the ultrafine hole, and the product precision is reduced. According to the technical solution, the machining device comprises a high-voltage power supply, a nozzle and a working electrode, wherein a suspension potential is arranged between the working electrode and the nozzle, a workpiece is placed in the suspension potential, the problems of carbon deposition and large deformation of a conventional electric discharge machining copper electrode are solved by the graphite electrode, the graphite electrode is small, the discharge energy of each pulse is small, the size of a discharge mark is small, the roughness of a machining surface is small as well, and the shape precision converted by the graphite electrode is high, so that the size precision of an ultrafine hole and the product quality are improved. The invention correspondingly discloses a method for machining the superfine hole through the graphite fine needle discharge, the surface roughness of the graphite electrode machined through a professional graphite milling cutter is small, and it is guaranteed that the machined superfine hole is high in size precision and smooth in surface.

Owner:途泰精密模具(苏州)有限公司

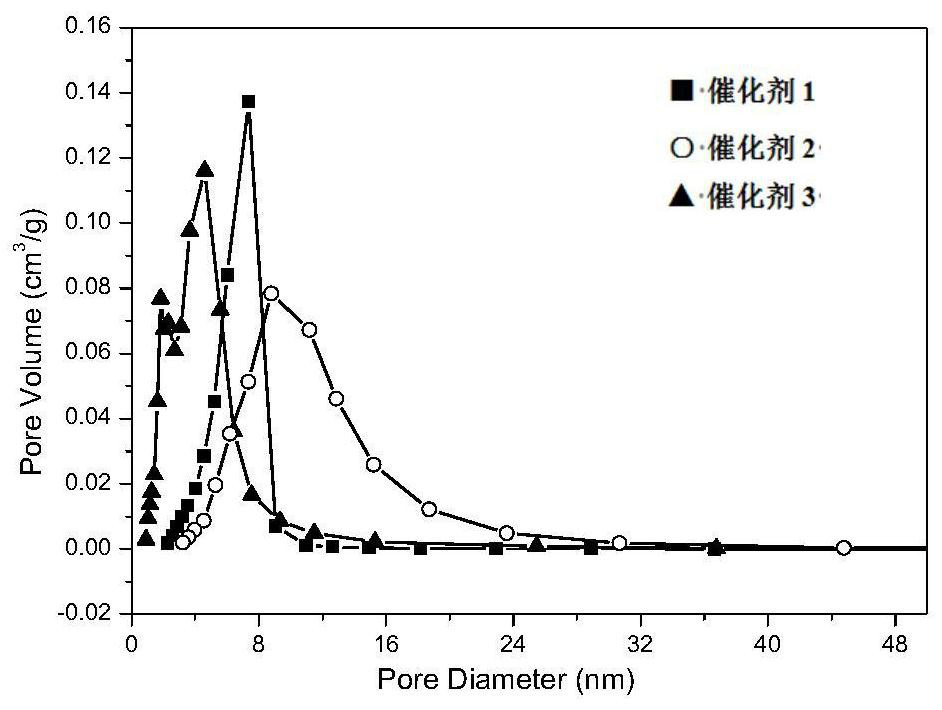

Catalyst for producing isobutene by dehydrogenating isobutane

InactiveCN112717919ALow selectivityHigh selectivityCatalyst carriersHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

The invention relates to a catalyst for producing isobutene by dehydrogenating isobutane, which takes VIB group elements in a periodic table of elements as main active components, at least one element in IIA group of the periodic table of elements as an alkaline assistant, at least one element in IVB group and VB group of the periodic table of elements as other assistants, and silicon-aluminum oxide as a carrier; wherein the carrier is treated by a hot solution containing group IIA elements in the periodic table of elements, and then is loaded with other components to obtain the dehydrogenation catalyst with the specific surface area of 100-300 m2 / g and the average pore size of 2-20 nm. The catalyst obtained by the method can improve the activity and selectivity of the isobutane dehydrogenation catalyst prepared by the prior art, and can be used for industrial application of isobutane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silencer for motorcycle exhaust pipe and assembly thereof

ActiveCN113339118AIncrease profitQuick disassemblyExhaust apparatusSilencing apparatusWater circulationMechanical engineering

The invention discloses a silencer for a motorcycle exhaust pipe and an assembly thereof. The silencer comprises a connecting mechanism, a waste gas emission control mechanism, a silencing combination, a water circulation heat dissipation combination and an assembly tail end mechanism, wherein a cavity is arranged in the connecting mechanism; the waste gas emission control mechanism comprises a fine adjustment part and an exhaust part; the exhaust part comprises a safety outer barrel, an inner core ring welded to the middle of an inner cavity of the safety outer barrel and an anti-seepage pad installed on the outer side of the safety outer barrel; and the silencing combination comprises an outer sleeve and an output pipe located in the middle of the outer sleeve. The inner side of the outer end of the outer sleeve is provided with an annular notch which is concave inwards, at the moment, the annular inner side of the outer sleeve is connected with an external connection port in an inserted mode, the outer sleeve and the external connection port are fixed through a fixing piece, meanwhile, an annular protrusion at the inner end of a cooling piece is used for fixing an interference inner barrel, therefore the exhaust pipe can be rapidly disassembled and assembled, and the problem that an existing exhaust pipe is difficult to disassemble can be solved.

Owner:XINGHUA FUBANG MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com