Piston with a skirt having oil flow slots and method of construction thereof

A piston and skirt technology, which is applied in the piston field of heavy-duty diesel engines, can solve the problems of reducing engine performance and engine life damage, and achieve the effects of reducing dynamic friction, reducing fuel consumption, and reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

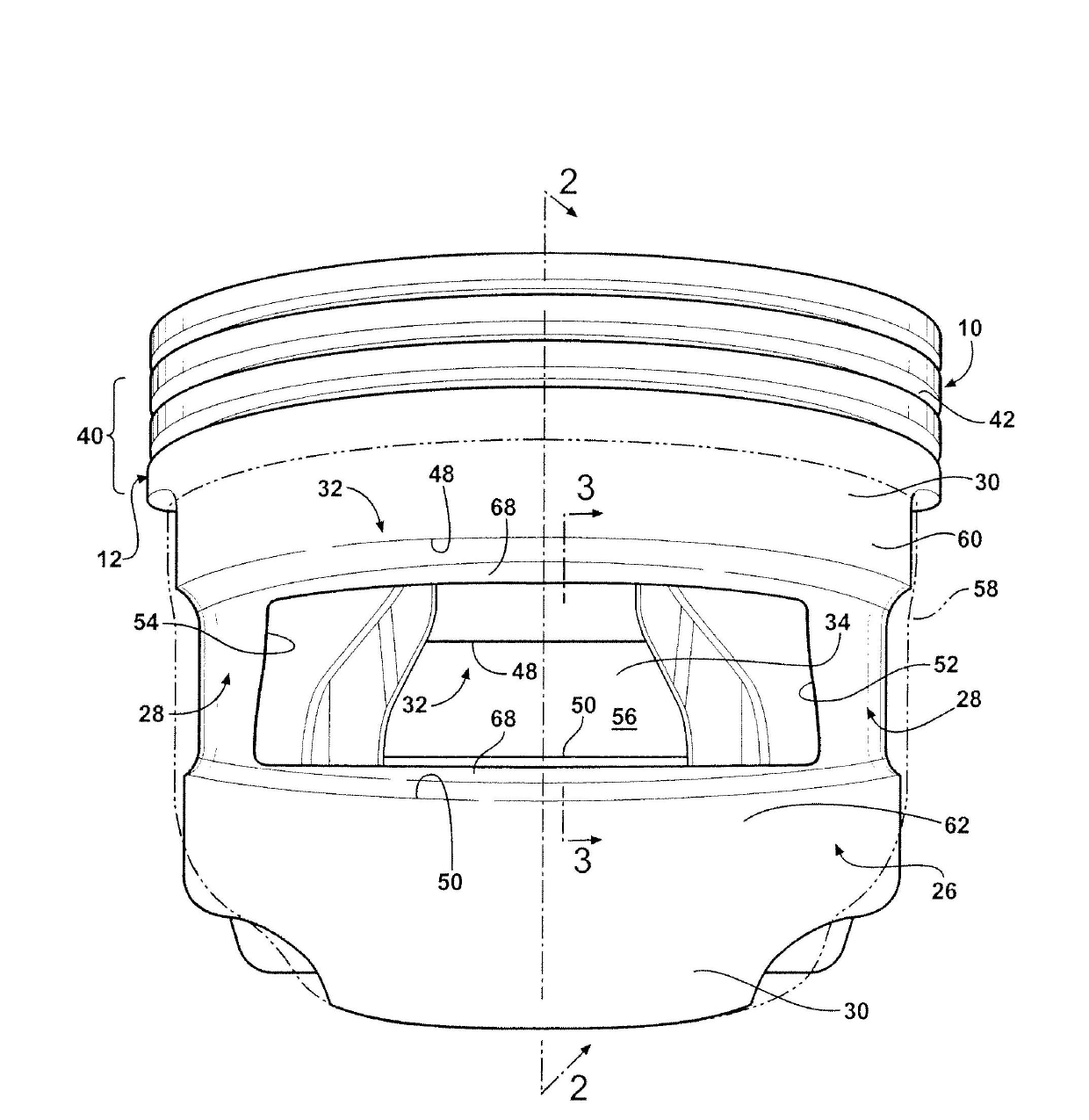

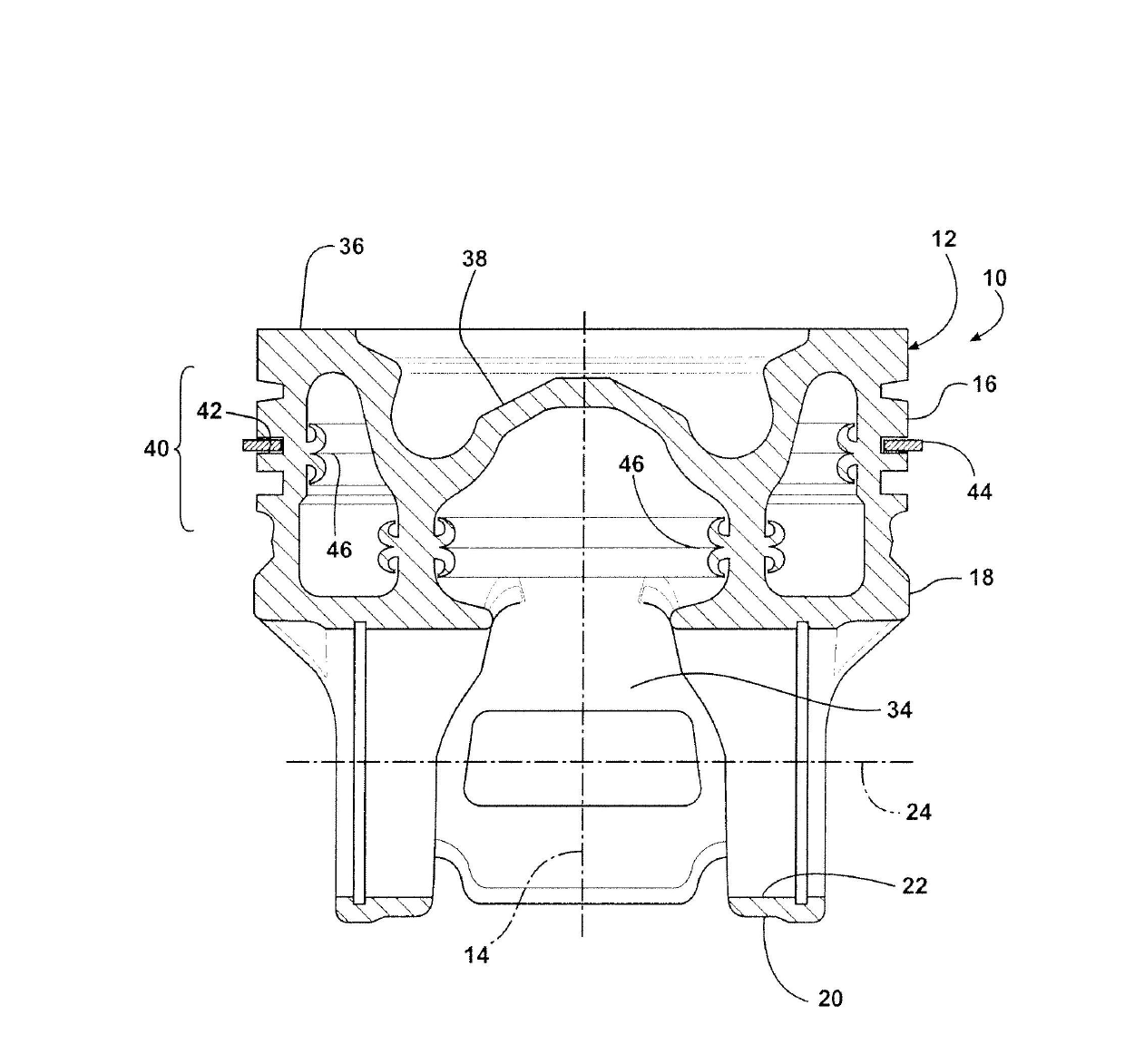

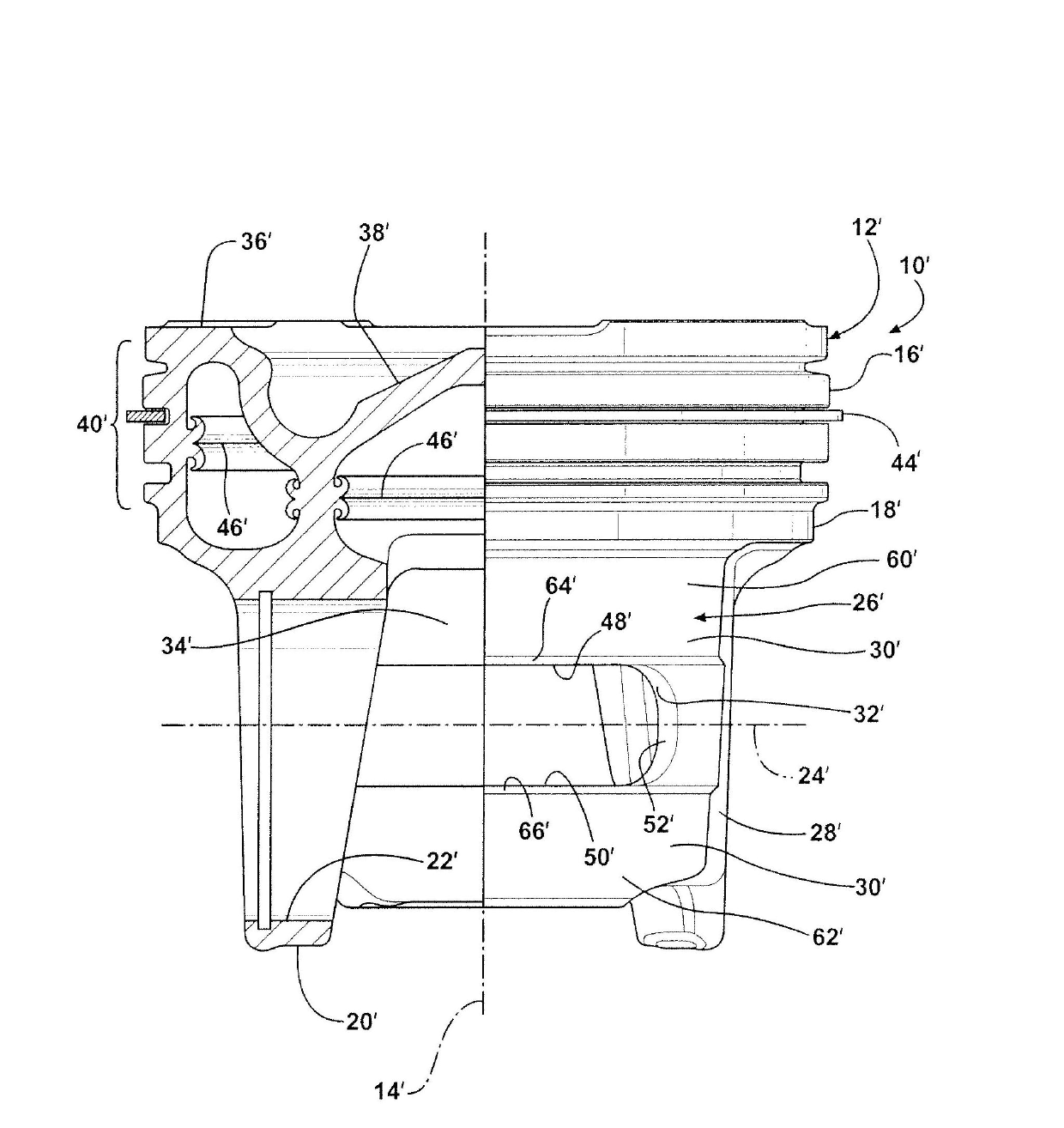

[0022] Referring to the drawings for more details, Figures 1 and 2 illustrate a piston 10 manufactured in accordance with a preferred embodiment of the present invention for reciprocating movement in a cylinder bore (not shown) of an internal combustion engine such as a diesel engine . The piston 10 has a body 12 extending along a central axis 14, the body 12 is either cast, forged, or made by any other manufacturing process, and the piston 10 is seated in the cylinder bore along the central axis 14. back and forth. By way of example, and not limitation, body 12 has an upper crown 16 connected to a lower crown 18 having a pair of pin seats 20 depending therefrom for providing laterally spaced pin holes 22 , the pair of pin holes 22 are aligned along a pin hole axis 24 that extends generally perpendicular to the central axis 14 . By way of example and not limitation, the pin seat 20 is connected by a support portion 28 to a laterally spaced skirt 26 to form a so-called "monob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com