Fluoropolyether group-containing polymer-modified organic silicon compound, surface treatment agent, and article

A technology of organosilicon compounds and polymers, applied in the direction of coating, etc., can solve problems such as insufficient wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

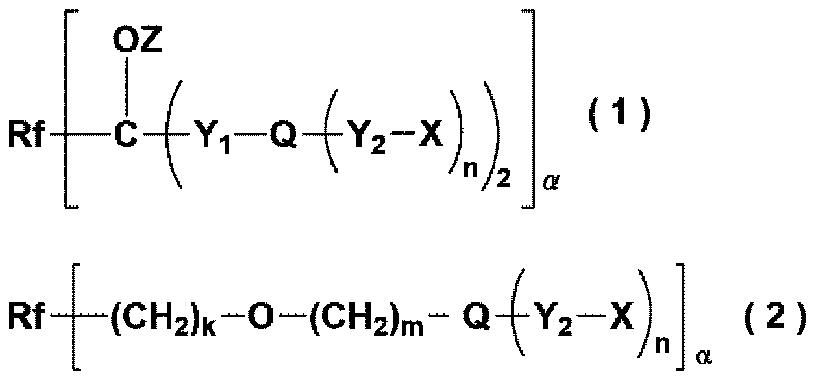

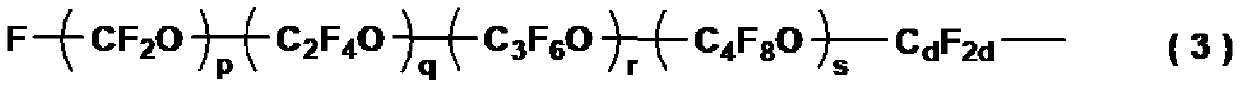

Method used

Image

Examples

Embodiment

[0281] Hereinafter, synthesis examples, examples, and comparative examples are shown, and the present invention will be described in more detail, but the present invention is not limited by the following examples.

[0282] In Examples and Comparative Examples, compounds obtained in the following Synthesis Examples were used.

Synthetic example 1

[0283] [Synthesis Example 1] Synthesis of Compound 1

[0284] 150 g of tetrahydrofuran and 300 g of 1,3-bis(trifluoromethyl)benzene were mixed in a reaction vessel, and 160 ml of 0.7 M allylmagnesium bromide was added dropwise. Then, slowly drop into the following formula (A)

[0285] [Chemical 53]

[0286]

[0287] p1:q1=47:53,

[0288] Represented compound 200g (4.8×10 -2 mol), heated at 60°C for 4 hours. After heating, it was cooled to room temperature, and the solution was dropped into 300 g of a 1.2M aqueous hydrochloric acid solution to stop the reaction. After recovering the fluorine compound layer as the lower layer by a liquid separation operation, it was washed with acetone. The washed lower fluorine compound layer was collected again, and the remaining solvent was distilled off under reduced pressure to obtain a fluoropolyether group-containing polymer represented by the following formula (B).

[0289] [Chemical 54]

[0290]

[0291] p1:q1=47:53,

...

Synthetic example 2

[0318] [Synthesis Example 2] Synthesis of Compound 2

[0319] In a reaction vessel, 100 g of 1,3-bis(trifluoromethyl)benzene, 8.2 g of DBU (diazabicycloundecene) (5.4×10 -2 mol), by the following formula (B)

[0320] [Chemical 59]

[0321]

[0322] p1:q1=47:53,

[0323] Represented compound 114g (2.7×10 -2 mol) after mixing, drop 5.8g (5.4×10 - 2 mol). Next, it heated at 50 degreeC for 3 hours. After heating, it was cooled to room temperature, and aqueous hydrochloric acid solution was added dropwise. After recovering the lower fluorine compound layer by a liquid separation operation, it was washed with methanol. The washed lower fluorine compound layer was collected again, and the remaining solvent was distilled off under reduced pressure to obtain a fluoropolyether group-containing polymer represented by the following formula (E).

[0324] [Chemical 60]

[0325]

[0326] 1 H-NMR

[0327] δ0-0.2(-OSi(C H 3 ) 3 )9H

[0328] δ2.4-2.6(-C H 2 CH=CH 2 )4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com