Durable bridge deck pavement structure suitable for concrete bridge and construction method of durable bridge deck pavement structure

A concrete and durability technology, applied in bridges, bridge parts, bridge materials, etc., can solve the lack of understanding of pavement structure functions and durability requirements, the difficulty of asphalt mixture to meet existing needs, adverse effects of economic and social development, etc. problems, to achieve the possible effects of improving adhesion and fixation, improving stress distribution, and reducing stress concentration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

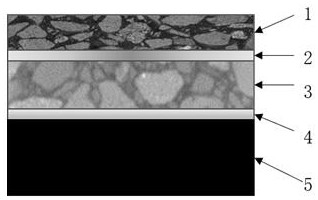

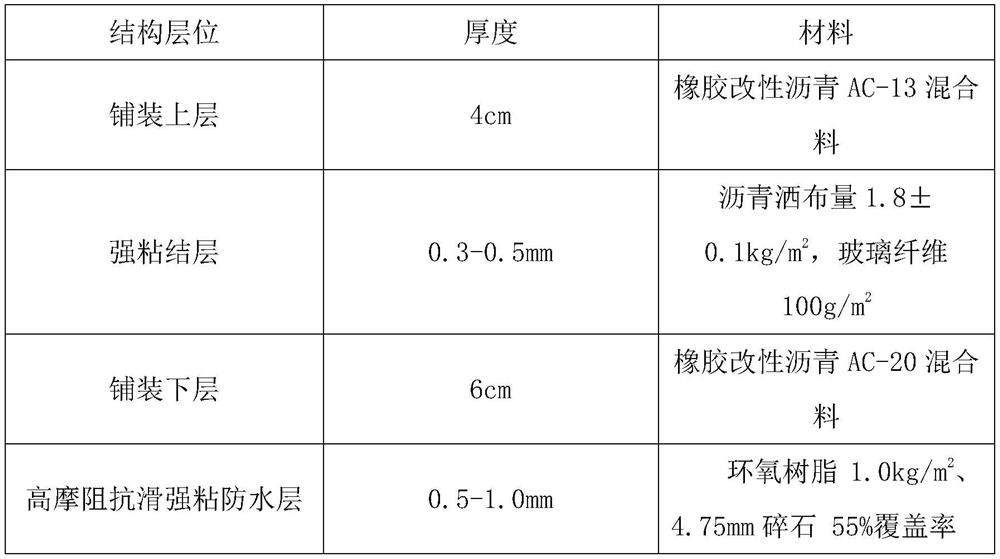

[0030] Such as figure 1 , a durable pavement structure suitable for concrete bridges, on the upper surface of the concrete cast-in-place layer from bottom to top, there are 0.5-1.0cm high-friction resistance sliding strong sticky waterproof layer 1, 6cm permanent structure layer 2 ( Pavement lower layer), 0.3-0.5mm strong bonding layer 3, 4cm anti-rutting, anti-cracking and wear-resistant layer 4 (pavement upper layer), the structural materials and thickness of each layer are shown in Table 1.

[0031] Table 1 Example 1 concrete bridge deck pavement structure

[0032]

[0033] In this embodiment, the high-friction, resistance-sliding, strong-adhesive waterproof layer is formed by synchronous spraying with epoxy resin binder and 4.75mm single-grain gravel. Among them, the coating amount of epoxy resin adhesive is 1kg / m 2 , the gravel coverage rate is 55%,

[0034] The epoxy resin used in this scheme is bisphenol F type epoxy resin NPEF-170 produced by Taiwan Nanya.

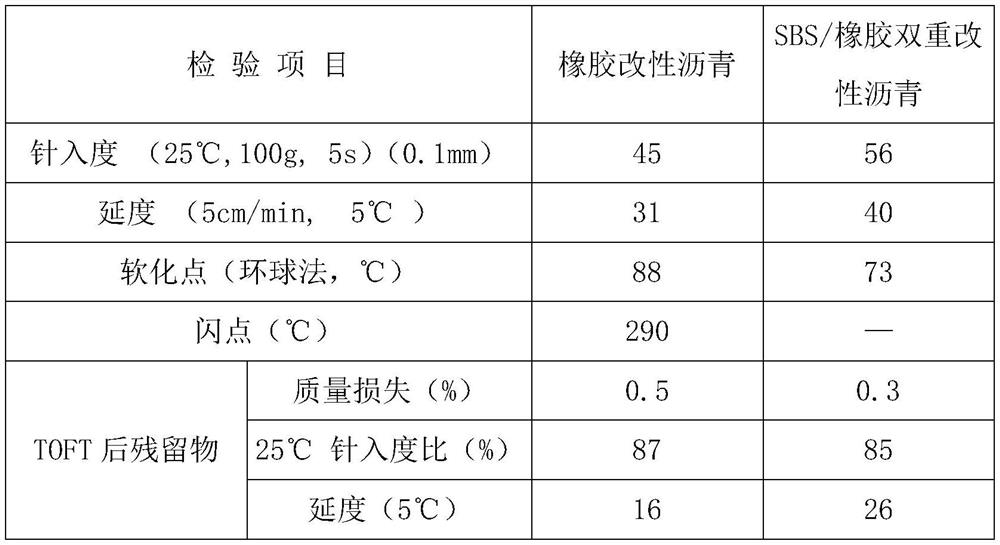

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com