A pipe processing mechanical arm

A technology for robotic arms and pipes, applied in the field of robotic arms, can solve problems such as hidden safety hazards, difficult control, and high labor intensity, and achieve the effects of eliminating hidden safety hazards, occupying less space, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

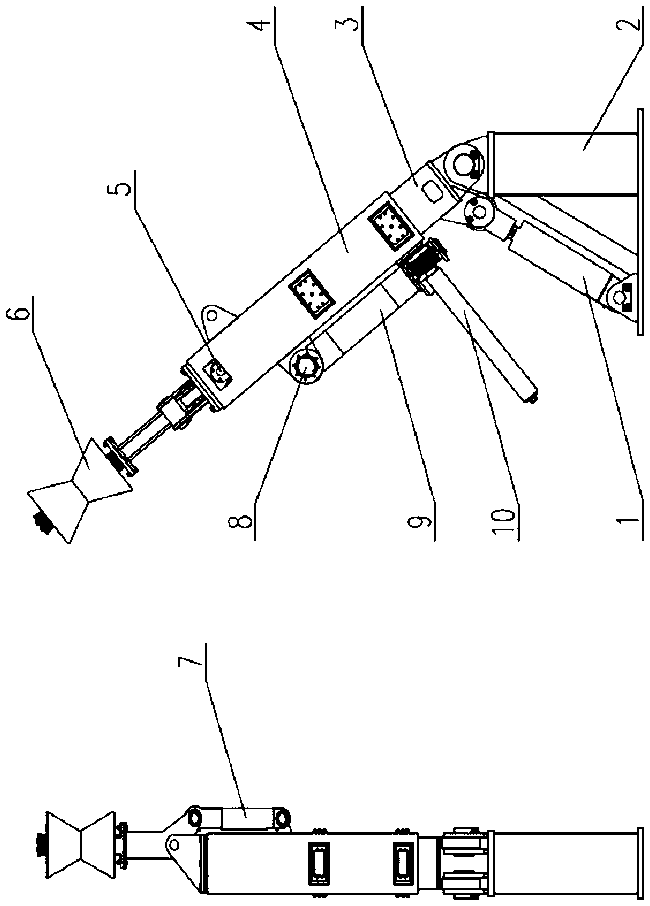

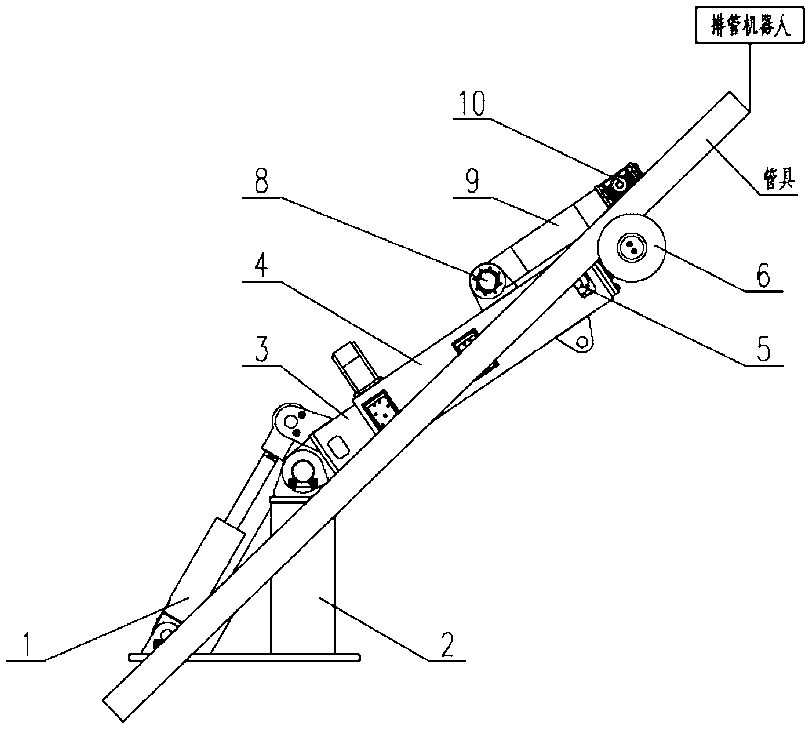

[0011] The Pipe Handling Robot is a robust integrated robot that guides drill pipe joints into ratholes. The pipe handling arm is bolted to the front end of the catwalk trolley and can handle pipe sizes from 2 7 / 8” to 36” without changing any parts.

[0012] When the pipe processing mechanical arm is working, the dumping cylinder (1) pushes the inner arm (3), and drives the outer arm (4) and its connected parts to rotate around the connecting pin on the top of the pillar (2) to the maximum angle and then Swivel, while rotating, the idler hydraulic cylinder (7) pushes the idler roller (6) to flip 90° inwardly in the direction perpendicular to the outer arm. When the drill pipe is pressed against the idler roller (6), the swing hydraulic cylinder (8) drives the rocker The arm (9) rotates 180° upwards, and at the same time, the rocker arm pressure roller (10) presses the drill pipe, and then the whole moves with the lifting of the drill pipe until the drill pipe is vertical, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com