Polyamide fiber oil

A technology of polyamide fiber and oil agent, applied in fiber processing, fiber type, textile and papermaking, etc., can solve the problems of polyamide fiber yellowing, excessive quality, and polyamide chemical fiber yellowing, etc., and achieve low metal friction, Good antistatic performance and low dynamic friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

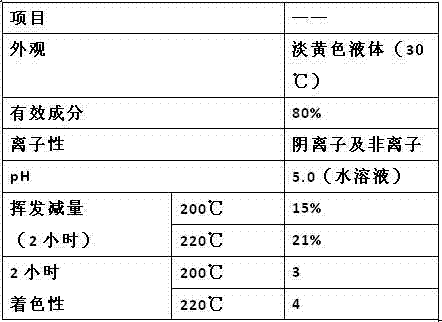

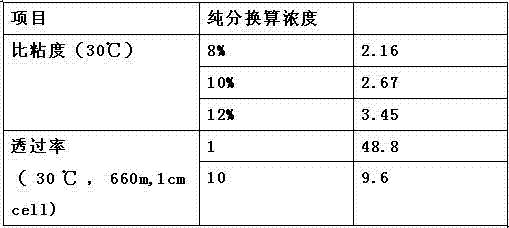

Image

Examples

Embodiment 1

[0016] A polyamide fiber oil, based on the total weight of the polyamide fiber oil, is mixed with the following components in percentage:

[0017] White oil, 30%; stearic acid, 6%; MOA3, 5%; succinic acid penetrant T, 20%; triethanolamine, 6%; lauric acid diester, 4%; oleic acid, 6%; Tween ( 80), 4%; MOA3PK, 8%; polyoxyethylene alkyl fatty ester, 8%; butyl cellosolve, 3%.

Embodiment 2

[0019] A polyamide fiber oil, based on the total weight of the polyamide fiber oil, is mixed with the following components in percentage:

[0020] White oil, 28%; stearic acid, 6%; MOA3, 5%; succinic acid penetrant T, 21%; triethanolamine, 6%; lauric acid diester, 5%; oleic acid, 5%; Tween ( 80), 5%; MOA3PK, 8%; polyoxyethylene alkyl fatty ester, 7%; butyl cellosolve, 4%.

[0021] The oil agent of the present invention should be made into an aqueous solution first, and then used by an oiling roller or a metering spray device. The suitable aqueous solution concentration is 10~15% by weight of solid silk. The appropriate oiling rate should be controlled at 0.6~2.0% of the fiber weight (based on the solid content of the oil agent) according to the thickness of the fineness. The concentration of the aqueous solution of the oil agent can generally be fixed at 10%.

[0022] In order to fully exert the performance of the oil agent, full attention should be paid to adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com