Gasoline additive and preparation method thereof

A gasoline additive, solvent oil technology, applied in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as harmfulness to human body, large amount of methanol usage, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

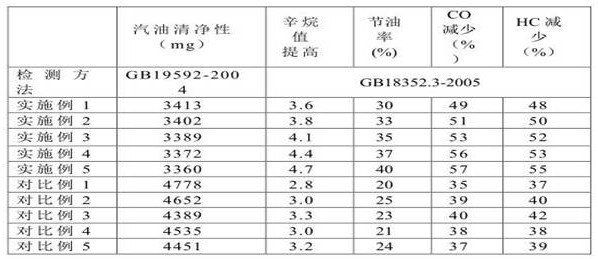

Examples

Embodiment 1

[0026] Embodiment 1 provides a kind of gasoline additive, is characterized in that, comprises the following components by weight: 4 parts of metal-organic nanomaterials modified by polyethylene glycol, 30 parts of solvent naphtha, 2 parts of tetrahydroxyglycoluril , 2-benzyltetrahydropyrrolo[3,4-c]pyrrole-1,3-dione 3 parts, quaternary ammonium salt-15 modified polyetheramine 1 part, diphenylguanidine 0.5 part, polyetheramine 4 Parts; The solvent oil is methanol.

[0027] The preparation method of the quaternary ammonium salt-15 modified polyether amine comprises the following steps: adding the quaternary ammonium salt-15 and polyether amine into an organic solvent, stirring and reacting at 40°C for 6 hours, and then rotary evaporating to remove the solvent , add the crude product, ethoxyacetic acid into water, stir at 50°C for 4 hours, and then remove the water by rotary evaporation to obtain quaternary ammonium salt-15 modified polyetheramine; the quaternary ammonium salt-15,...

Embodiment 2

[0030] Embodiment 2 provides a kind of gasoline additive, is characterized in that, comprises the following components by weight and is made: 4.5 parts of metal-organic nanomaterials modified by polyethylene glycol, 33 parts of solvent naphtha, 2.5 parts of tetrahydroxyglycoluril , 2-benzyltetrahydropyrrolo[3,4-c]pyrrole-1,3-dione 3.5 parts, quaternary ammonium salt-15 modified polyetheramine 1.2 parts, diphenylguanidine 0.7 parts, polyetheramine 5 parts Parts; The solvent oil is ethanol.

[0031] The preparation method of the quaternary ammonium salt-15 modified polyetheramine comprises the following steps: adding the quaternary ammonium salt-15 and polyetheramine into an organic solvent, stirring and reacting at 45°C for 6.5 hours, and then removing the solvent by rotary evaporation , add the crude product, ethoxyacetic acid into water, stir at 53°C for 4.5 hours, and then remove the water by rotary evaporation to obtain quaternary ammonium salt-15 modified polyetheramine; t...

Embodiment 3

[0034] Embodiment 3 provides a kind of gasoline additive, is characterized in that, comprises the following components by weight: 5 parts of metal-organic nanomaterials modified by polyethylene glycol, 35 parts of solvent naphtha, 3 parts of tetrahydroxyglycoluril , 4 parts of 2-benzyltetrahydropyrrolo[3,4-c]pyrrole-1,3-dione, 1.5 parts of quaternary ammonium salt-15 modified polyetheramine, 0.7 part of diphenylguanidine, 6 parts of polyetheramine Parts; The solvent oil is 2-ethylhexanol.

[0035] The preparation method of the quaternary ammonium salt-15 modified polyetheramine comprises the following steps: adding the quaternary ammonium salt-15 and the polyetheramine into an organic solvent, stirring and reacting at 50°C for 7 hours, and then rotary evaporating to remove the solvent , add the crude product, ethoxyacetic acid into water, stir at 55°C for 5 hours, and then remove the water by rotary evaporation to obtain quaternary ammonium salt-15 modified polyetheramine; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com