Machining device and method for machining ultrafine hole by adopting graphite fine needle electric discharge

A technology of electric discharge machining and machining device, which is applied in the field of machining devices using graphite fine needle EDM machining of ultra-fine holes, can solve the problems of residual thermal stress on the surface of workpieces, inability to meet the dimensional accuracy requirements of ultra-fine holes, easy carbon deposition and consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

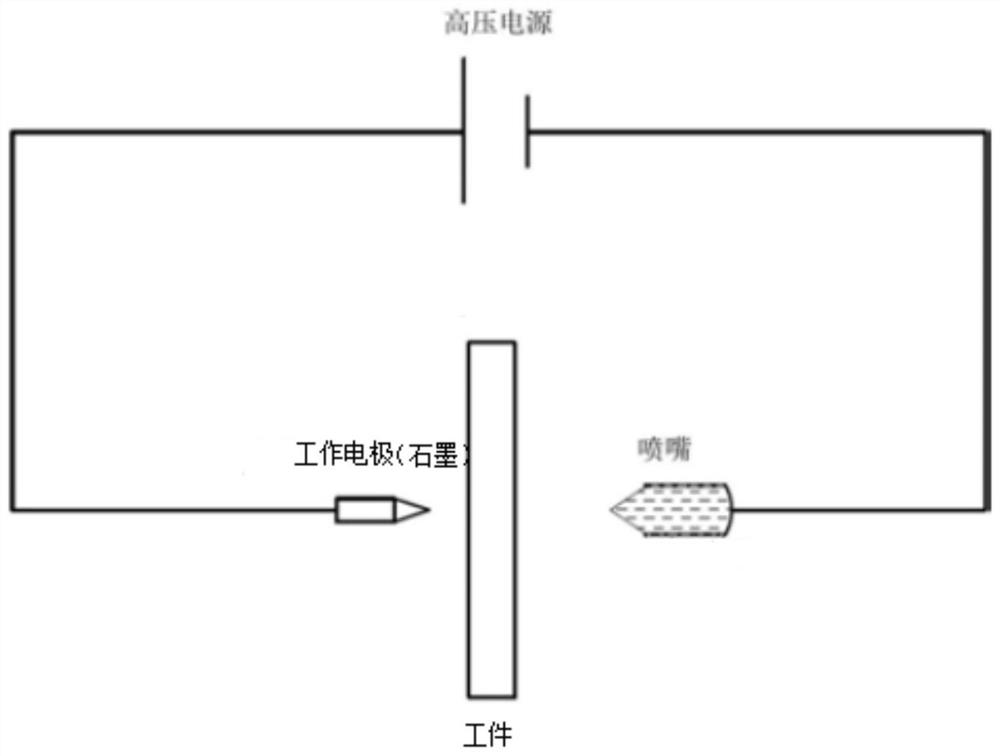

[0029] refer to figure 1 , which is a processing device that uses graphite fine needle electric discharge machining pores disclosed in the present invention, comprising a high-voltage power supply, a nozzle and a working electrode respectively connected to the high-voltage power supply, the end of the working electrode far away from the high-voltage power supply and the end of the nozzle far away from the high-voltage power supply There is a floating potential between them, and the workpiece to be processed is placed in the floating potential, and the high-voltage electrostatic field strength between the nozzle and the working electrode is 15000V / m. In this embodiment, the working electrode is isostatic graphite, which has the characteristics of high-purity and fine-grained graphite. The dense structure of isostatic graphite ensures its strength and no slag during processing, thus improving the problems of carbon deposition and large deformation of conventional electric discha...

Embodiment 2

[0031] The preparation process of graphite electrode comprises the following steps,

[0032] Step 1. Choose isostatic graphite and use a special graphite milling cutter D2 round nose cutter;

[0033] Step 2. Rough machining of the machine tool. Install the fine graphite needle on the chuck of the machine tool, turn on the machine tool, adjust the processing parameters, set the spindle speed to 10000r / min, the feed rate to 70mm / min, and the cutting amount to 0.3mm. Processed to a graphite fine needle diameter of 0.5mm;

[0034] Step 3, machine tool finishing, finishing machining until the diameter of the graphite fine needle is 0.04mm.

[0035] In this embodiment, the precision tolerance of the graphite fine needle is +0.003mm.

[0036] The graphite electrode processed by a professional graphite milling cutter has small surface roughness and high precision, plus the advantages of small micro-discharge pulse energy, small discharge trace size, and small gap error, which can en...

Embodiment 3

[0038] The preparation process of graphite electrode comprises the following steps,

[0039] Step 1. Select isostatic graphite and use a special graphite milling cutter D3 round nose cutter;

[0040] Step 2. Rough machining of the machine tool. Install the fine graphite needle on the chuck of the machine tool, turn on the machine tool, adjust the processing parameters, set the spindle speed to 35000r / min, the feed rate to 70mm / min, and the cutting amount to 0.6mm. Processed to a graphite fine needle diameter of 0.5mm;

[0041] Step 3, machine tool finishing, finishing machining until the diameter of the graphite fine needle is 0.04mm.

[0042] In this embodiment, the precision tolerance of the graphite fine needle is +0.005mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com