A method for removing dissolved oxygen in oil products

A technology for dissolved oxygen and oil products, applied in chemical instruments and methods, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems of low deoxidation efficiency of gasoline, and achieve the effects of complete deoxidation reaction, prolonged catalyst life and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

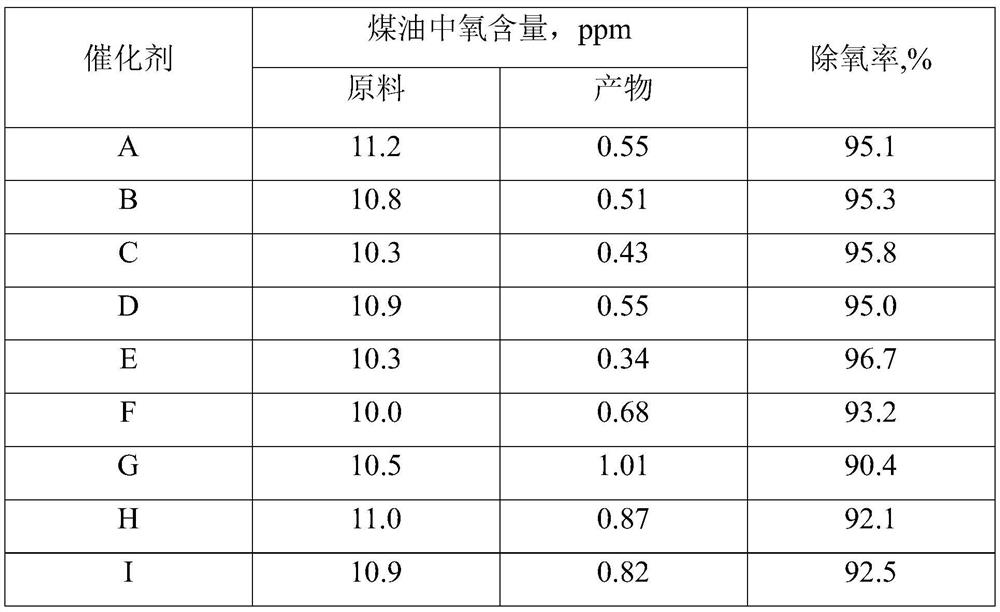

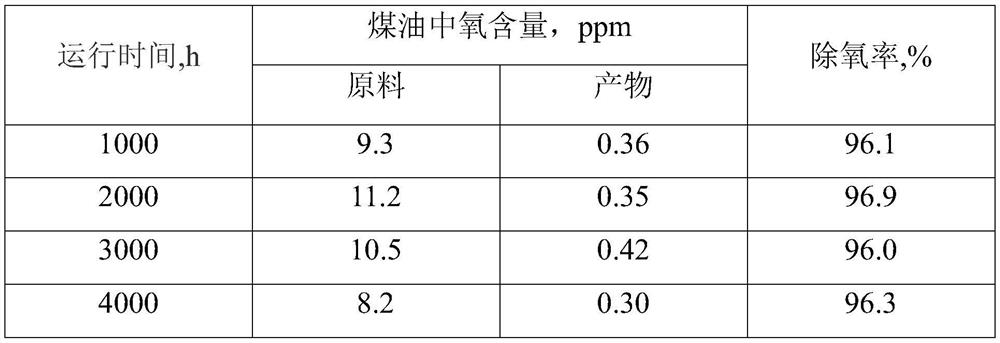

Examples

Embodiment 1

[0031] The preparation of embodiment 1 catalyst A

[0032] In this example, an alumina powder with two types of pores (the pore size distribution ranges of the two types of pores are 10-20nm and 150-300nm respectively) is used to prepare the second layer of carrier, and mullite is used as the first layer of carrier , effectively combined to obtain a carrier containing inner and outer layers, and to prepare a catalyst.

[0033] Take 500 grams of high-purity Al 2 o 3 powder, 196 grams of high-purity SiO 2 Powder, 70 grams of water, 10 grams of 10% nitric acid were mixed, kneaded for 1 hour, pressed into pellets, placed in a closed space at 70°C under constant temperature and humidity conditions and continued to react for 10 hours, and then dried at 150°C for 2 hours. Then bake at 1450° C. for 1 hour to obtain the first layer of carrier pellets with a diameter of 2.0 mm. XRD analysis showed mullite crystal form.

[0034] Take 50 grams of alumina powder (with two types of por...

Embodiment 2

[0037] The preparation of embodiment 2 catalyst B

[0038] In this example, alumina powder with one type of pores (the pore size distribution range is 15-30nm) is used, and the pore-forming agent methylcellulose is added to prepare the second layer of carrier with two types of pores, and mullite As the first carrier, it is effectively combined to obtain a carrier containing inner and outer layers, and a catalyst is prepared.

[0039] The first layer of carrier was prepared according to the method of Example 1.

[0040] Take 50 grams of alumina powder (with one type of pores, the pore size distribution range is 15-30 nm), 20 grams of 20% nitric acid, 12 grams of methyl cellulose, and 600 grams of water are mixed and stirred to prepare alumina slurry. Molded according to the method of Example 1, a carrier containing inner and outer layers was obtained. Analysis showed that the thickness of the second layer of support was 110 μm, and the ratio of the diameter of the first layer...

Embodiment 3

[0043] The preparation of embodiment 3 catalyst C

[0044] In this example, an alumina powder with two types of pores (the pore size distribution ranges of the two types of pores are 8-18nm and 200-500nm respectively) is used to prepare the second layer of carrier, and mullite is used as the first layer of carrier , effectively combined to obtain a carrier containing inner and outer layers, and to prepare a catalyst.

[0045] The first layer of carrier was prepared according to the method of Example 1.

[0046] Take 50 grams of alumina powder (with two types of pores, the pore size distribution ranges of the two types of pores are 8-18nm and 200-500nm respectively), 20 grams of 20% nitric acid, and 600 grams of water are mixed and stirred for 2 hours to prepare alumina material pulp. Molded according to the method of Example 1, a carrier containing inner and outer layers was obtained. Analysis showed that the thickness of the second layer of support was 240 μm, and the rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com